Chromalox PQ410-4 User Manual

Page 5

-5-

14.

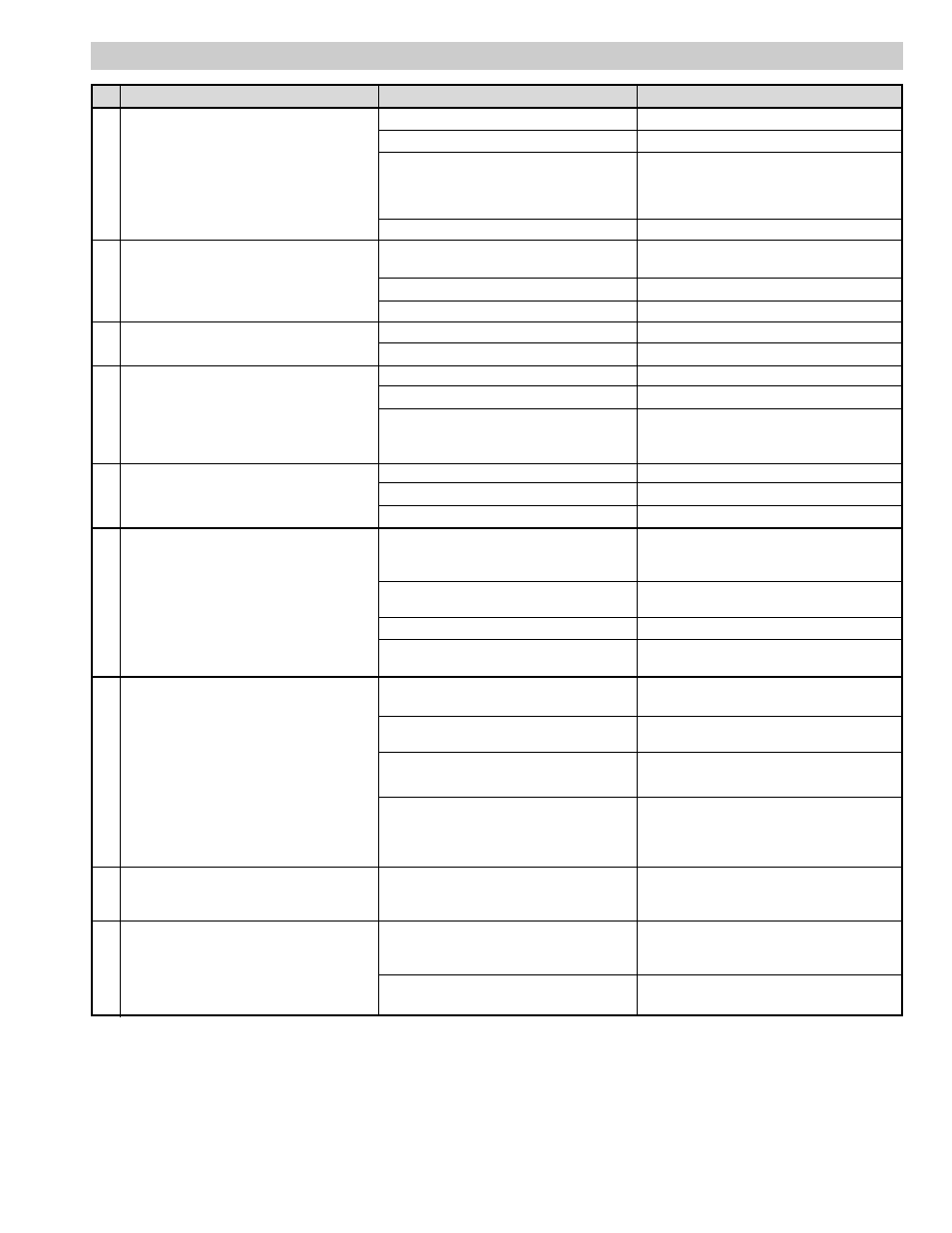

STANDARD HEAT TRANSFER SYSTEM TROUBLE SHOOTING CHART

Problem

Cause

Corrective Action

Main power feed off

Turn on main power

Circuit breaker off

Turn on circuit breaker

A

Power light off

Control transformer

Primary fuse blown

Replace fuse

Secondary fuse blown

Replace fuse

Transformer bad

Check and/or replace

Pilot light blown

Replace bulb

Float switch open

Add oil to system

B

Power light on, pump will not start

If no float switch, jumper terminals 4 & 5

Motor overloads tripped

Reset overloads, check running current

Motor starter bad

Check motor starter coil

C

Power light on, pump light on, motor

Motor fuse blown

Replace fuse, check motor overloads

not running

Motor burned out

Replace motor, check motor for overload

Broken belt

Check and replace belt

D

Power light on, pump light on, motor

Broken coupling

Check and replace coupling

running, pump not running

Turn off system and rotate pump by hand

Pump jammed by slag or foreign object

if jammed, disassemble and clean pump.

Check and clean strainer.

Power light on, pump light on,

Control relay #1 not closed

See M

E

motor running, pump running heat

Heat on-off switch in off position

Turn switch to on

will not come on

Process control ITC-1 set too low

Set process control to desired temperature

See items, pump noisy, see O;

No oil flow

insufficient suction pressure, see J:

high discharge pressure, see K

F

Insufficient heat

Process piping too small or restricted

Check process piping, check heat transfer

area of platen, etc.

Heater fuses blown

Check and replace fuses

Heater elements burned out

Check continuity and resistance of

elements

Excessive operating pressure over

See K

40 psig

Packing gland loose

Check and adjust packing gland nuts per

manufacturer’s recommendations

G

Pump packing gland leaking

Use mechanical seals or sealless pumps

Wrong pump specified

where no oil leaks can be tolerated

Mechanical seals on pumps should be

water cooled over 350°F.

Improper cooling of seals

Failure to do so will cause seal failure

and leaks.

Check piping and flange alignment

H

System leaks when filling

Rough handling during shipment

retighten and torque all bolts to

specifications

Expansion and contraction due to

Check all flange bolts and connections

temperature has loosened connections

retighten and torque to manufacturer’s

I

System leaks at temperature and after

specifications

cool down

Wrong gasket materials

Replace gaskets as necessary, use spiral

wound or Grafoil

®

gaskets