Note, Two speed adjustment, Handle adjustment – MTD 215-370 A User Manual

Page 5: Tailpiece adjustment

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

NOTE

NOTE

A brief break-in period is essential to

insure maximum engine life. This con

sists of running the engine at half speed

for a period of time required to use one

tank of gasoline. This is necessary on

the initial run only. It is also recom

mended that the oil be changed after

five (5) hours of operation. This allows

for

the

removal

of

impurities

which

may have accumulated during the break-

in

period.

Subsequent

oil

changes

should be made as stated in the engine

manual. Always check oil before using

your tiller especially during the break-in

period. Be sure oil level is adequate.

The Low Speed Groove for the 5 H.P.

tiller is the groove closest to the engine.

The Low Speed Groove for the 8 H.P.

tiller is the groove towards the oper

ator. See figure 8.

The High Speed Groove for the 5 H.P.

tiller is the groove towards the operator.

The High Speed Groove for the 8 H.P.

tiller is the groove closest to the engine.

See figure 8.

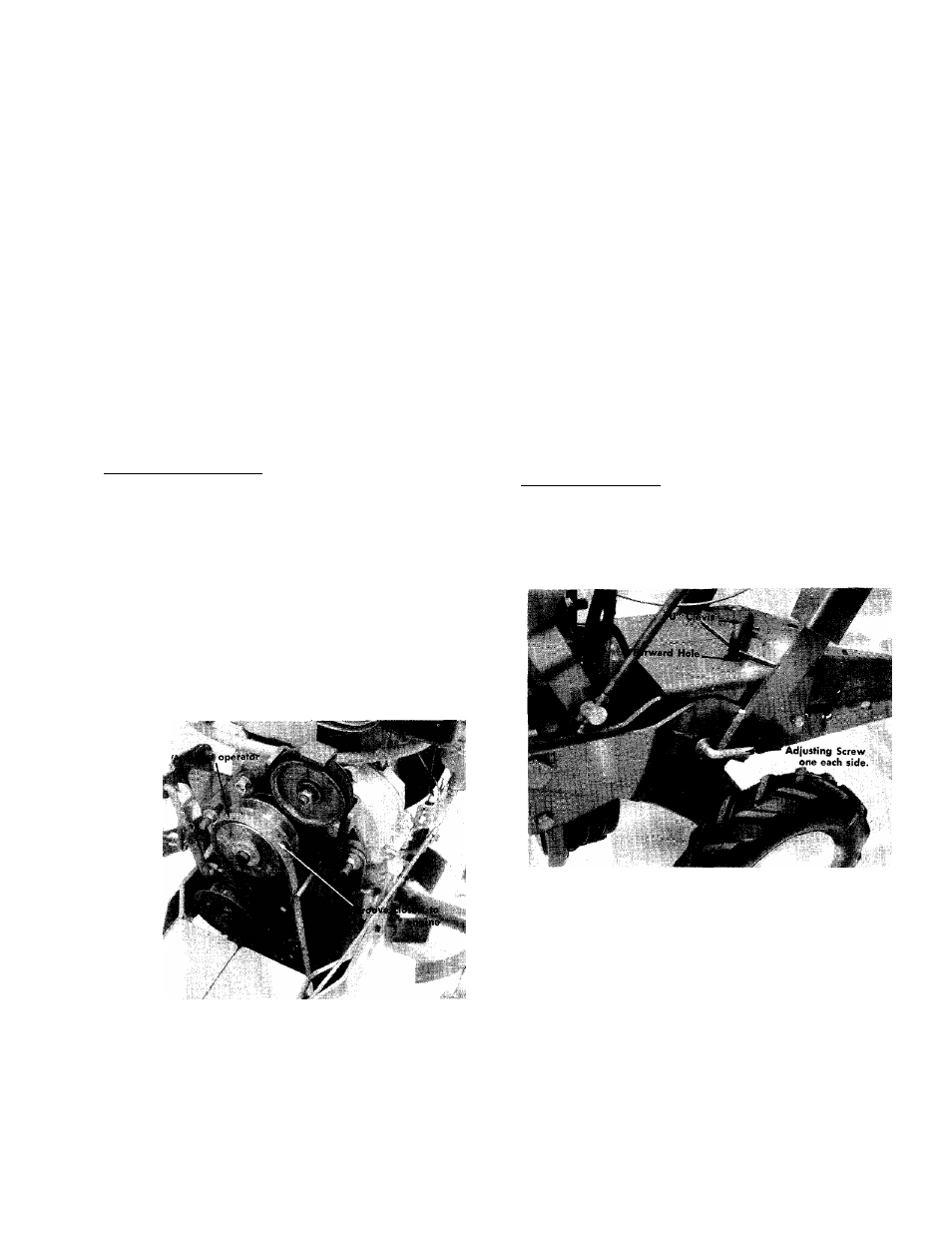

TWO SPEED ADJUSTMENT

Your tiller can be operated in two speed ranges. See

figure 8.

The forward drive belt can be in either the high speed

groove or the low speed groove. The soil condition

determines the best speed range for your tiller.

To change belt from one groove to the other, shut off

the engine remove the spark plug wire and ground,

pull the clutch control lever into REVERSE with your

left hand and move the belt on the upper pulley to

the other groove. Repeat with the lower pulley.

Groove tow

HANDLE ADJUSTMENT

The handle may be adjusted to five different heights

by loosening the adjusting screw (and pulling it out

enough to clear the notches) on each side of the handle

and pivoting the handle up or down. See figure 9.

FIGURE 9. HANDLE ADJUSTMENT

FIGURE 8. TWO SPEED ADJUSTMENT

TAILPIECE ADJUSTMENT

The tailpiece can be made stationary or free floating.

To be free floating simply lift the "U" clevis and rotate

"U" clevis to engage forward hole and push down.

See figure 9. See figure 2 for stationary position.