Maintenance and lubrication, A warning, Mower blade maintenance – Troy-Bilt 14094 User Manual

Page 10: Mower blade maintenance (continued), Lubrication

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Section 4

Maintenance and Lubrication

A WARNING

BEFORE

PERFORMING

ANY

MAINTENANCE,

OR ADJUSTMENTS

TO

THE UNIT, SHUT OFF ENGINE, REMOVE

KEY

AND

DISENGAGE

AHACHMENT/PTO

DRIVE. WAIT FOR ALL MOVING PARTS

TO STOP. FAILURE TO FOLLOW THESE

INSTRUCTIONS MAY RESULT IN

PERSONAL INJURY.

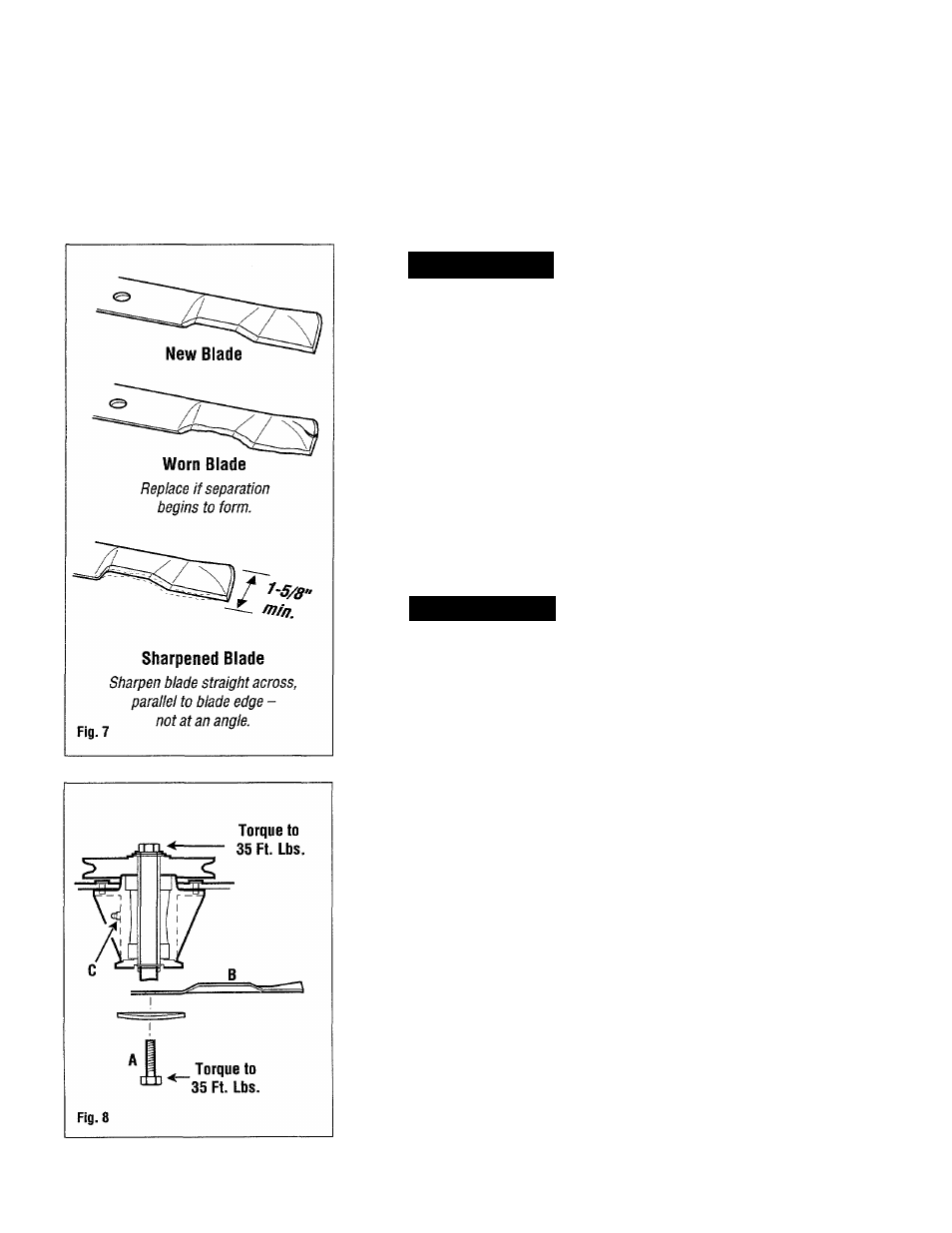

Mower Blades

Examine mower blades before each use.

Check for blade wear. See Fig. 7.

A WARNING

BEFORE REMOVING OR REPLACING THE

MOWER BLADES, SHUT OFF ENGINE,

REMOVE KEY AND DISENGAGE

ATTACHMENT/PTO DRIVE. USE

CAUTION WHEN SHARPENING MOWER

BLADES. WEAR GLOVES OR WRAP

MOWER BLADES WITH RAGS.

Mower Blade Maintenance

For efficient mowing, always keep cutting

edges of mower blades sharp. Examine

mower blades for wear. Re-sharpen

blades when they begin to dull.

Blade Removal:

Remove bolt (A, Fig. 8) and washer.

Remove mower blade (B).

Mower Blade Maintenance

(continued)

Blade Sharpening:

Grind or file the same amount from

each blade end to maintain mower

blade balance. An unbalanced mower

blade produces excessive vibration

and may damage spindle bearings.

Sharpen cutting edge straight across -

parallel to rear edge of mower blade.

See Fig. 7. After sharpening, check

mower blades on a blade balancer.

Blade Installation:

Install mower blades (B) as shown in

Fig. 8 with flat side down. Blades are

identical and may be installed

randomly on each spindle. Torque

bolts (A, Fig. 8) to 35 ft. lbs. (47 Nm).

Lubrication

The mower deck has two grease fittings

(C, Fig. 8 and 9), beneath the mower deck

on each blade spindle. See Figs. 8 and 9.

1.

Lubricate gage wheels (D, Fig. 9) and

anti-scalp wheels (E) with oil every

100 operating hours or twice yearly.

2.

Lubricate spindle grease fittings;

Remove mower deck (page 11)

and turn it upside down. Clean

fittings before lubricating.

Lubricate grease fittings every 50

hours of operation or yearly with

multi-purpose grease. (2 - 3

strokes from a grease gun per

fitting.)

a.

b.

10