Chain sharpening, Filing chisel chain – Poulan 1980-02 User Manual

Page 8

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

w BE CAREFUL! The chain will be moving during thii

procedure.

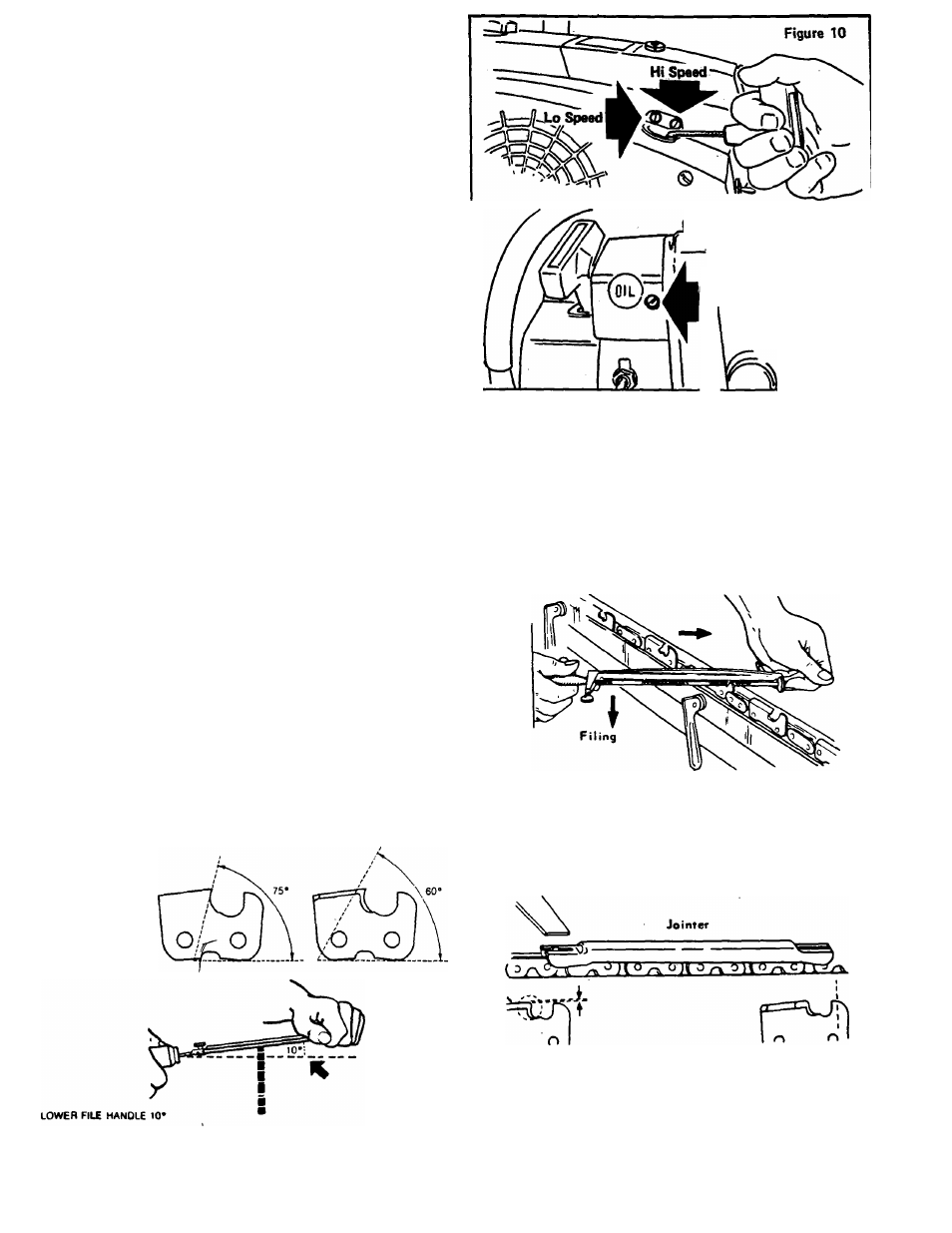

1. Stop the engine.

2. Turn the high speed and low speed mixture screws clock

wise

until they stop. (Figure 10) Don't tighten

them, you may damage the needle seats!

3. Turn the high speed and low speed mixture screws one

full turn counterclockwise

4. Start the engine. If it stops, increase the idle speed by

turning the idle speed screw clockwise

. (Figure 11)

5. Run the engine for a few minutes to bring it up to opera

ting temperature.

6. Set the idle speed as fast as possible without the chain

moving. Turn the idle speed screw clockwise

for

faster idle, counterclockwise

for slower idle.

7. Squeeze the trigger quickly. If the engine stops, restart it.

The engine should accelerate without hesitating when the

trigger is squeezed. If it does not. turn the low speed

mixture screw counterclockwise

1/16 of a turn and

check the acceleration again. If the idle speed slows while

adjusting the low speed mixture, reset the idle speed as in

step 6. Continue step 7 until acceleration is smooth.

8. Make a test cut with the saw.

9. If the engine seems to smoke excessively in the cut, turn

the high speed mixture screw clockwise

1/16 of a

turn. Repeat step 8 and 9, if necessary. WARNING; The

high speed needle must never be less than 7/8 turn open.

Too lean of a setting will quickly ruin the engine.

10. If the engine seems to weaken or lose power in the cut.

^

\ \ Figure 11

Idle Speedz.

Adjustment

^1^

J_

turn the high speed mixture screw counterclockwise

1/16 of a turn at a time until the saw cuts smooth

ly. The high speed mixture screw should not be open

more than VA turns (counterclockwise

) from the

stopped position in step 2.

11. Reset the idle speed (see step 6).

CHAIN SHARPENING

A.properly sharpened chain is the secret of effortless, trouble

free cutting. Your authorized dealer or authorized master ser

vice center will be happy to answer your question on chain

sharpening and supply whatever materials you need. To avoid

any delay, while working, carry a spare sharp chain and do

your sharpening after you have completed cutting.

FILING CHISEL CHAIN

To properly sharpen your chain, you will need a fileholder, the

correct size file and jointer. Follow these instructions;

1. If possible, remove the chain from the saw and put it an a

saw chain filing vise. If you do not have a filing vise, tension

the chain up snugly on the guide bar.

2. There are three angles that must be maintained for a pro

perly sharpened chain. These are; (a) 30° Top Plate Filing

Angle, (b) 60° Top Plate Cutting Angle, (c) and 75° Side

Plate Angle. All three angles can be maintained accurately

by using a No. 55047 Fileholder and holding it in the right

position.

v' !

' 30* —"

3. Using a 3/16" dia. file, press the flat side of the file holder

firmly against the top of the cutters.

4. Lower fileholder handle down 10°below horizontal position.

5. Maintain 30° mark on file holder parallel to the chain.

6.

Push the file through the cutter, from inside out while

holding the holder in the position outlined above. Apply

pressure on the forward stroke only.

7. To set all depth gauges at the same level, place the jointer

over each depth gauge and file the depth gauge with a flat

file until it is level with the jointer, then round off the lead

ing edge of each depth gauge.

8

63793

2/80

printed in U.S.A.