Service notes, Drive belt slips, Reverse drive wheel adjustment – MTD 219-360 User Manual

Page 6: Adjustments - (see fig. 4), To check, To adjust

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SERVICE NOTES

DRIVE BELT SLIPS

1.

Lubricate contact surface between pivot bracket

assembly and adjustment plate.

2. Check pivot bracket assembly locknuts for excessive

tightness.

3. Check control rod for improper assembly. If adjust

ment tube is attached to lower end instead of upper

end, it may bind on control lever and prevent full

use of tension spring.

4.

If spring tension is still insufficient, adjust to

another mounting hole on control lever.

5. Some measure of belt adjustment may be made by

loosening the mounting bolts on the adjustment plate

and moving as needed. This adjustment is usually

used for reverse drive wheel adjustments.

6. Large pulley and belt may be rubbing on lower belt

guard,

7. Idler pulley must operate freely.

8. Belt guard or clips must not touch the belt when it

is tightened.

REVERSE DRIVE WHEEL ADJUSTMENT

1. Reverse drive wheel should line up with its matching

pulley. If it does not, loosen pulley to which revers

ing drive wheel is attached and align as needed.

When reassembling, tighten set screw securely.

2. Matching pulley for reversing drive wheel can be

mounted one way only. The reversing drive wheel

must operate in the deeper groove.

3. If belt retainer touches engine pulley after adjust

ment, move to outside mounting or bend away as

needed.

4.

Additional reverse adjustment may be made by

loosening the mounting bolts on the adjustment plate

and moving as needed.

5. Reverse should operate only when control handle

assembly is held in reverse position. Adjust control

rod for proper operating position.

NOTE: If belts are excessively stretched, replacement

will be necessary.

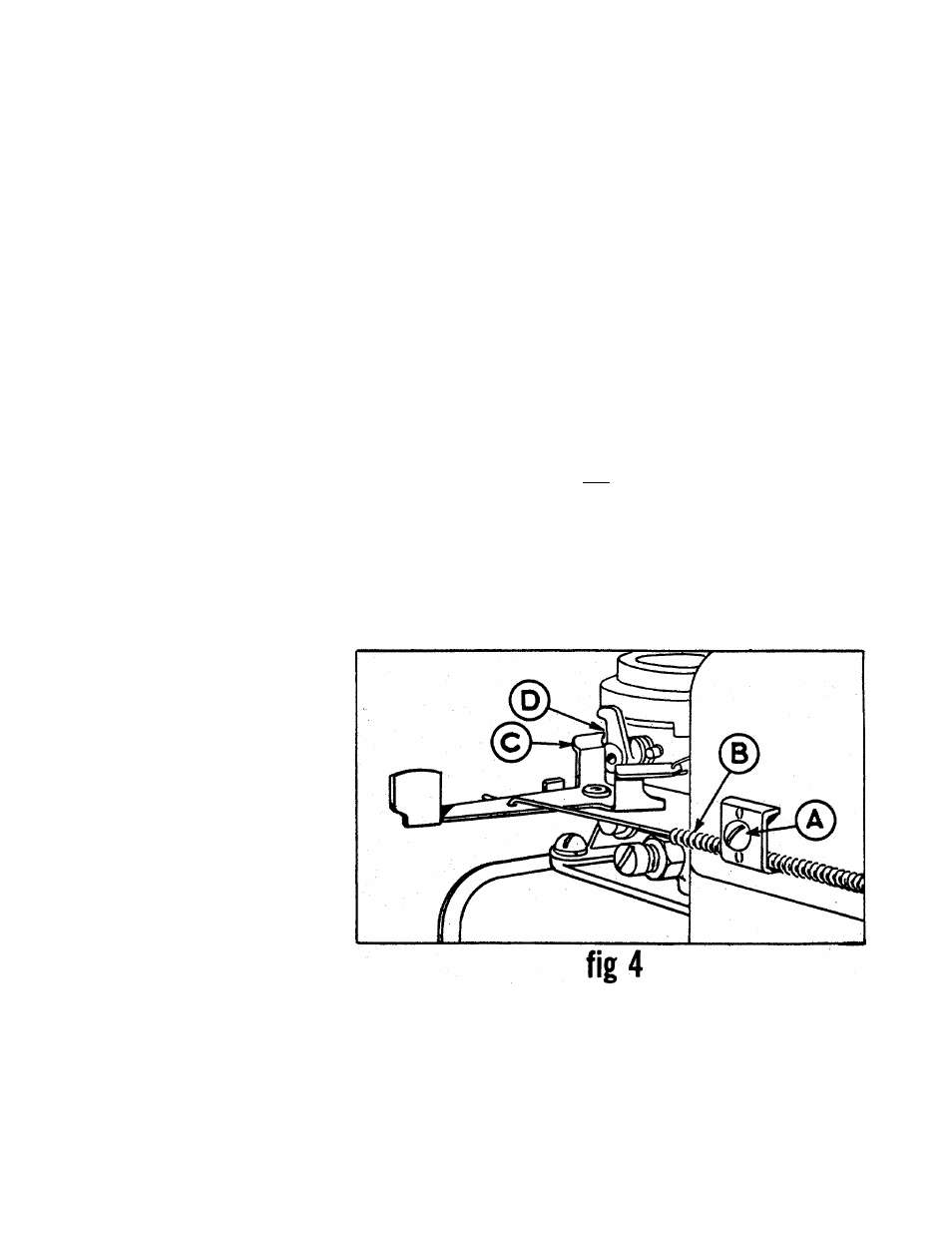

ADJUSTMENTS - (see fig. 4)

To Check:

Remove Air Cleaner. Move Throttle

Assembly to CHOKE position. The

carburetor

choke should then be

closed. Move the Throttle to STOP.

Control lever on carburetor should

then make good contact with stop

switch to short out ignition.

To Adjust:

Place Throttle on equipment in FAST

(high speed) position. Lever “C” on

carburetor should be just touching

choke arm at “D”. To adjust, loosen

casing clamp screw “A” on blower

housing. Move control casing ”B”

forward or backward until correct

position is obtained. Tighten screw

“A”. Recheck above operation and

replace Air Cleaner.

NOTE:

This instruction manual covers various models and all'accessories

shown do not necessarily apply to your model tiller.

MT-D PRODUCTS INC extends its warranty only on

the tiller. If repairs or service is needed on the engine,

please contact your nearest, authorized engine service

outlet. Check tiie “Yellow Pages” of your telephone

book under “Engines — Gasoline.”

Find It Fast

In Th*

'Yellow Pages'

FORM NO.770-1884H

PRINTED IN U.S.A.