A warning, A caution – Carrier 58DXC User Manual

Page 4

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Step 3—Wiring

1. Disconnect yellow wire from heat exchanger differential

pressure switch (PRS) on inducer housing; add splice connec

tor to this wire.

2. Connect uninsulated terminal of one yellow wire (provided in

kit) to the splice connector; connect other end to terminal C on

low gas pressure switch (LGPS) on gas valve.

3. Connect insulated terminal of second yellow wire (provided in

kit) to terminal NO on pressure switch LGPS; connect other

end to pressure switch PRS.

4. Route yellow wires along wire harness; secure wires with wire

tie provided.

Step 4—Check Furnace Operation and Make Necessary

Adjustments

1. Ensure gas and electrical supplies to furnace are OFF.

2. Attach manometer at manifold pressure tap on downstream

side of gas valve.

3. Set room thermostat to “call for heat.”

4. Turn ON gas supply manual shut-off valve.

A WARNING

Never use a match or other open flame to check for leaks. Use

a soap-and-water solution. Failure to follow this warning

could result in personal injury or death.

16. With main burners ignited, check pressure tap plug for gas

leaks.

BURNER FU\ME

5. Turn furnace gas valve control knob ON and check all

threaded pipe connections for gas leaks.

6. Turn ON electrical supply to furnace.

7. When hot surface ignitor glows, check it for cracks in silicon

carbide.

8. When burners ignite, check manifold orifices for gas leaks.

9. Gas input rate for propane gas is the same as for natural gas.

See furnace rating plate for input rate. Input rate for propane

is determined by manifold pressure. Set manifold pressure at

10.5-in. wc. To adjust manifold pressure, turn adjustment

screw for gas valve regulator either counterclockwise (out) to

decrease pressure, or clockwise (in) to increase pressure.

NOTE;

The manifold pressure must always be measured with the

burner enclosure front removed.

10. Replace regulator seal cap.

11. Replace burner enclosure front.

A CAUTION

Ensure burner enclosure front is in place after adjustment has

been made.

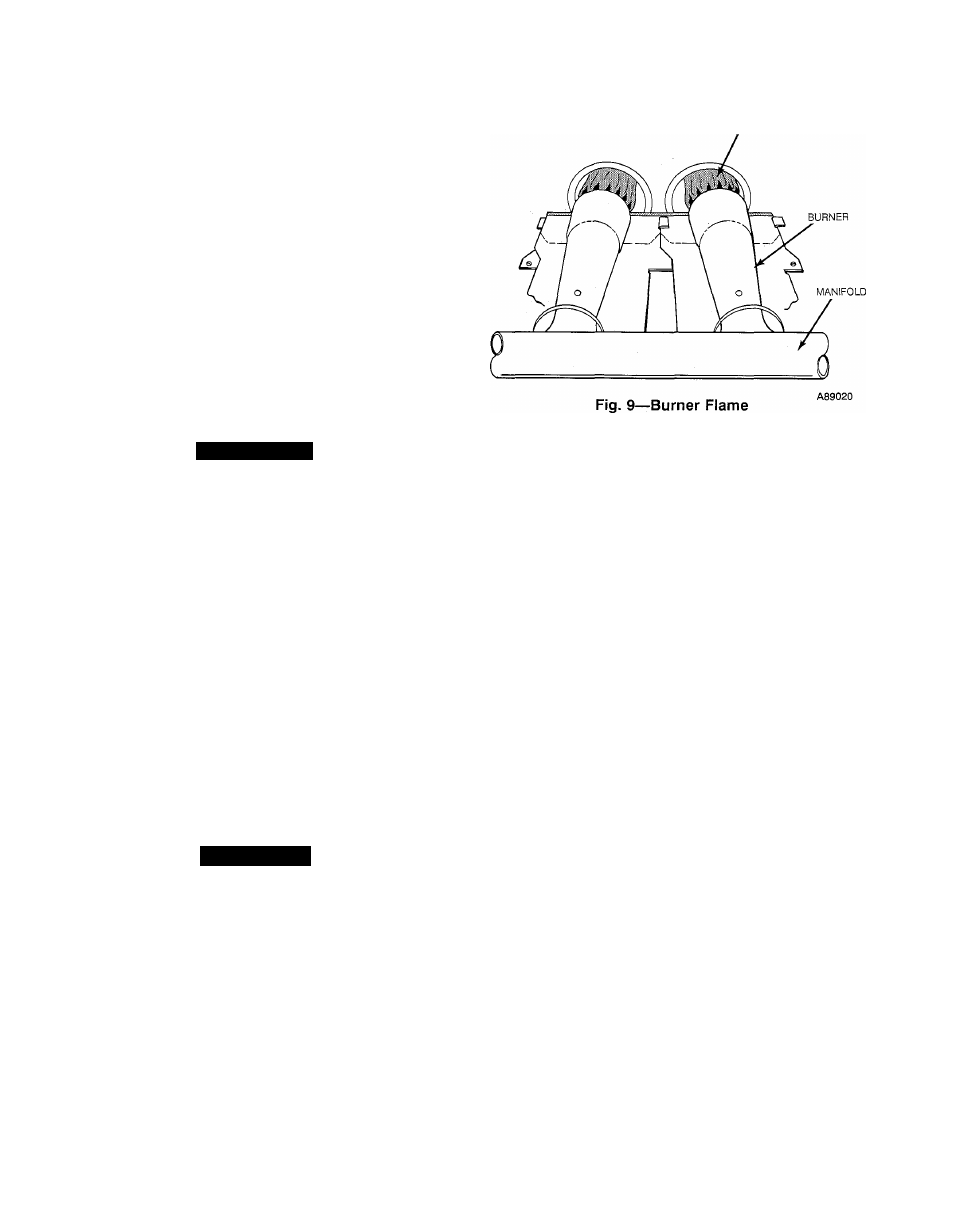

12. Look through sight glass in burner enclosure and check burner

flame. Burner flame should be clear blue, almost transparent.

(See Fig. 9.)

13. Turn furnace gas valve control knob OFF.

14. Remove manometer and replace manifold pressure tap plug.

15. Turn furnace gas valve control knob ON.

Step 5—Check Pressure Switch Operation

The newly-installed pressure switch is a safety device used to

guard against possible ignition of unburned gas in the combustion

chamber. Adverse burner operating characteristics can result from

low gas supply pressure.

This normally-open switch closes when gas is supplied to the gas

valve under normal operating conditions. The closed switch

completes the control circuit.

Should an interruption or reduction in the gas supply occur the gas

pressure at the switch drops below the pressure switch setting and

the switch opens. Any interruption in the control circuit (in which

the pressure switch is wired) instantly closes the gas valve and

stops gas flow to the burners.

When normal gas pressure to the gas valve is restored, the system

must be electrically reset to re-establish normal heating operation.

Before leaving the installation, observe unit operation through a

few complete heating cycles. During this time, turn OFF the gas

supply to the gas valve just long enough to completely extinguish

the burner flame, then instantly restore the full gas supply to the

gas valve. To ensure proper pressure switch operation, observe that

there is no gas supply to the burners until after the hot surface

ingitor begins glowing.

Step 6—Label Application

1. Fill in Conversion Responsibility Label (310167-354) and

apply it to front of blower access door.

2. Attach Gas Control Conversion Label (310148-301) to burner

enclosure front. (See Fig. 1 or 2.)

3. Attach Furnace Conversion Rating Plate (310168-384) on left

side of furnace near existing furnace rating plate. (See Fig. 1

or 2.)

NOTE:

Discard labels and instructions packed with White-

Rodgers regulator spring conversion kit.

4. Replace furnace control access door.

5. Set room thermostat to desired temperature.

Copyright 1991 Carrier Corporation Indpis, IN 46206

15027

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

BookI 1

I

4 PC 101

Catalog No. 565-972 Printed in U.S.A. Form 58D,S-28SI

Pg 4

8-91

Replaces: 58D,S-21 SI

Tab 16al8a