Upflow furnace filter table, Downflow furnace filter table, Combustion area and vent system – Carrier 58RAP User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

5. Inspect the filter. If tom, replace the filter.

6. Wash the filter (if dirty) in a sink, bathtub, or outside with

a garden hose. Always use cold tap water. A mild liquid de

tergent may be used if necessary. Spray water through the

filter in the opposite direction of airflow (through the

cross-mesh binding side). Allow filter to dry.

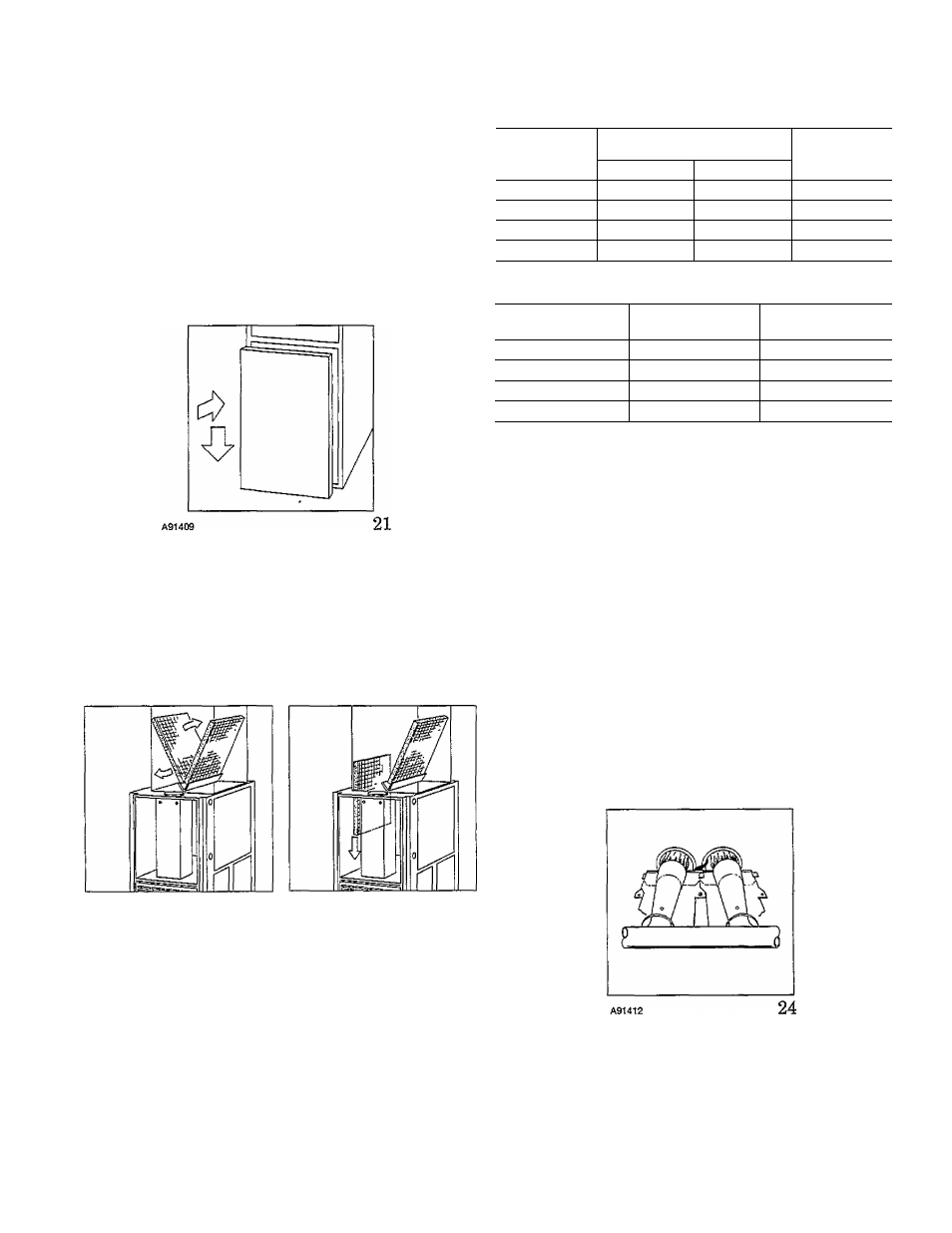

7. Reinstall the clean filter with its cross-mesh binding side

facing the furnace blower.

8. Put filter retainer back in the bracket opening and lock it

in place.

9. Replace the blower and control access doors and turn ON

electrical power to your furnace. (See Fig. 15,16, and 21.)

NOTE: If side return ducts are used, two filters may be required

in some models. The procedure listed above may be used to re

move side filters.

• DOWNFLOW FURNACES ONLY:

TVo filters are located in the return-air plenum above the

blower (above line-of-sight) resting in the V-shaped channel on

top of the furnace. (See Fig. 22.)

1. lUrn OFF electrical supply to the furnace. (See Fig. 18.)

2. Remove blower access door after removing 2 screws.

3. Remove left side filter by tipping the filter top toward the

center—^raise it firom the V-shapped channel in which it

rests. (See Fig. 22 and 23.)

A91410

22

A91411

23

4. Lower filter down along side of the blower and remove from

the furnace.

5. Tb remove the second filter, lift from V-shaped channel

and remove the same way as left side filter.

6. Inspect the filters. If tom, replace the filter.

7. Wash the filters (if dirty) in a sink, bathtub, or outside

with a garden hose. Always use cold tap water. A mild liq

uid detergent may be used if necessary. Spray water

through the filter in the opposite direction of airflow

through the cross-mesh binding side. Allow filter to dry.

8. Reinstall clean filters with the cross-mesh binding side

facing the furnace blower.

9. Replace blower door (secure with 2 screws) and turn ON

electrical power to your furnace.

UPFLOW FURNACE FILTER TABLE

FURNACE

CASING

FILTER SIZE

WIDTH

Side Return

Bottom Return FILTER TYPE

14-3/16

(1) 16x25x1*

(1) 14x25x1

Cleanable

17-1/2

(1)16x25x1*

(1) 16x25x1

Cleanable

21

(1) 16 X 25 X 1 (1) 20 X 25 X 1* Cleanable

24-1/2

(2) 16 X 26 X 1 (1) 24 X 25 X 1* Cleanable

DOWNFLOW FURNACE FILTER TABLE

FURNACE

CASING WIDTH

FILTER

SIZE

FILTER

TYPE

14-3/16

(2) 16 X 20 X 1*

Cleanable

17-1/2

(2) 16 X 20 X 1*

Cleanable

21

(2) 16x20x1*

Cleanable

24-1/2

(2) 16 X 20 X 1*

Cleanable

* Factory provided with the furnace. Filter may be field modified

by cutting as required. Alternate sizes and additional filters

may be ordered from your dealer.

COMBUSTION AREA AND VENT SYSTEM

Inspect the combustion area and vent system before each heat

ing season. An accumulation of dirt, soot, or rust can mean a

loss of efficiency and improper performance. Buildups on the

main burners or pilot assembly can cause faulty firing. This

“delayed ignition” is characterized by an alarmingly loud

sound. If your furnace makes a loud noise when the main burn

ers are ignited by the pilot, shut down the furnace—call your

servicing dealer. Refer to the lighting instructions label on the

blower door for shutdown procedures.

Use your flashlight and follow these steps for inspecting the

combustion area and vent system of your furnace:

1. Thm off the electrical supply to the furnace and remove

the access doors. (See Fig. 8 and 9, or 10.)

2. Carefully inspect the gas burner (see Fig. 24) for dirt, rust,

or scale. Then, inspect the relief box, flue connection area,

and the vent pipe for mst.

NOTE: If dirt, rust, soot, or scale accumulations are found, call

your servicing dealer. DO NOT OPERATE THE FURNACE.

3. Inspect the vent pipe for a sag, holes, or a disconnection. A

horizontal vent pipe must slope upward. If msty joints or

seams, or signs of water leakages are found call your dealer

for service.