Operating instructions (continued), User-maintenance instructions – Campbell Hausfeld IN715501AV User Manual

Page 6

4 . Release the pusher . Allow pusher to

rest against nails . The nailer is now

loaded .

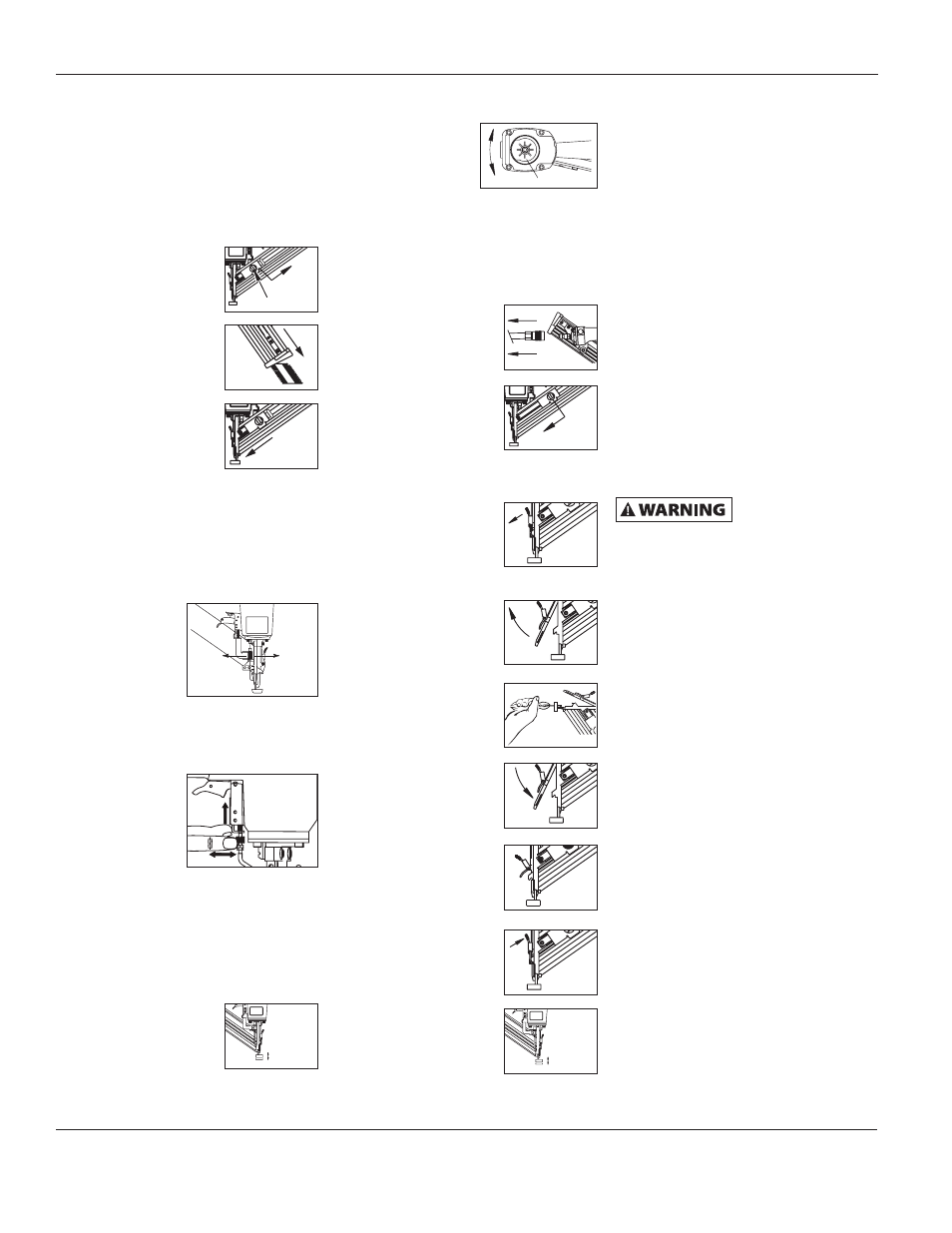

UNloADiNG THE NAilEr

1 . Always unload all fasteners before

removing tool from service .

Unloading is the

reverse of loading,

except always

disconnect the

air hose before

unloading .

2 . Pull nail pusher

mechanism back and

press “Nail Bypass

Button .”

3 . Hold tool upright so

nails will slide out of

magazine .

4 . Release the Pusher .

ADJUsTiNG

THE NAil

pENETrATioN

The NB356502 is

equipped with an

adjustable depth

of drive feature . This allows the user to

determine how deep a fastener will be

driven into the work surface .

1 . Adjust the

operating

pressure to a

pressure which

will consistently

drive the

fasteners . Do not exceed the

maximum operating pressure of the

nailer of 110 psi .

2 . To increase depth of drive, first

pull up on the upper WCE, then

rotate thumbwheel to the left

(counter-clockwise) .

To decrease depth

of drive, rotate

thumbwheel to the

right (clockwise) . Then release upper

WCE into detents which hold the

6

Operating Instructions

www.chpower.com

opErATiNG iNsTrUCTioNs

(Continued)

thumbwheel in place after each

adjustment .

3 . Make sure that

the trigger and

work contact

element (WCE)

move freely up and down without

binding or sticking after each

adjustment .

ADJUsTiNG THE DirECTioN oF THE

EXHAUsT

The NB356502 is

equipped with an

adjustable direction

exhaust deflector . This

is intended to allow

the user to change the

direction of the exhaust .

Simply twist the deflector

to any direction desired .

ClEAriNG A JAM FroM THE Tool

1 . Disconnect the air

supply from the tool .

2 . Remove all nails from the magazine

(see "Loading/

Unloading The

Nailer") . Failure to

do so will cause the

nails to eject from the

front of the nailer .

3 . Undo latch by pulling

out and down .

The wire latch will

disengage from the

hooks on the nose .

4 . The door can now be

rotated, exposing the

jammed fastener .

5 . Remove the jammed

fastener, using pliers

or a screwdriver if

required .

6 . Rotate door back into

the closed position .

7 . Extend the wire latch and place over

the hooks on the nose .

8 . Close the latch by pushing the latch

up and in until the latch snaps into

place .

9 . Make sure the trigger and work

contact element (WCE) move freely

up and down without sticking or

binding .

UsEr-MAiNTENANCE

iNsTrUCTioNs

TECHNiCAl sErviCE

Please call our Tool Hotline at 1-800-

543-6400 with any questions regarding

the operation or repair of this tool or

for additional copies of this manual .

FAsTENEr AND rEplACEMENT

pArTs

Use only 15 gauge

35° fasteners.

Use only genuine Campbell Hausfeld

replacement parts. Never substitute

parts. Do not use modified parts or

parts which will not give equivalent

performance to the original equipment.

Tool performance, safety and durability

could be reduced. When ordering

replacement parts or fasteners, specify

by part number.

Tool rEpAir

Only qualified personnel should repair

the tool and they should use genuine

Campbell Hausfeld replacement parts

and accessories, or parts and accessories

which perform equivalently .

AssEMBlY proCEDUrE For sEAls

When repairing a tool, the internal

parts must be cleaned and lubricated .

Parker O-lube or equivalent must be

used on all o-rings . Each o-ring must be

coated with O-lube before assembling .

A small amount of oil must be used on

all moving surfaces and pivots . After

reassembling, a few drops of 30W

non-detergent oil or equivalent, must

be added through the air line before

testing .

sTorAGE

The stapler should be stored in a cool

dry place .

Rotate

rotate

Pusher

Mechanism

Nail

Nail Bypass Button

COUNTER-

CLOCKWISE

CLOCKWISE

Movement

Movement

Movement

Movement