Engine care – Winco DL6000HE/E User Manual

Page 11

11

3072-10

60707-125

circuits to be powered during the outage to the emer-

gency panel. Keep in mind only a limited amount of

amperage is available from the generator set. Some

circuit breakers may still have to be turned off to

prevent an overload on the generator during the initial

start up. See the nameplate on your generator for

the amperage capabilities of your unit.

CAUTION: EQUIPMENT DAMAGE

Failure to properly limit and balance the load ap-

plied to the generator will cause the generator to

produce low voltage and may damage the engine

generator set. It may also cause severe damage to

the loads connected to the generator at that time. Im-

proper loading of the generator set constitutes abuse

and will not be covered by warranty.

ENGINE CARE

If major engine service or repair is required, contact

an authorized engine service center. The manufac-

turer of these engines has established an excellent

world-wide engine service organization. Engine ser-

vice is very likely available from a nearby authorized

dealer or distributor. Check the yellow pages of your

local telephone directory under “Engines-Gasoline”

for the closest engine repair center or ask the dealer

from whom you purchased the power plant.

1. Change the oil after the fi rst 20 hours of opera-

tion and yearly or 100 hours thereafter under normal

operating conditions. Change engine oil every 50

hours of operation if the engine is operated under

heavy load, or in high ambient temperatures.

a. Start the engine and warm it up, stop the engine

and remove the spark plug wire to prevent it

from accidently being started.

b. Remove oil drain bolt at base of the engine

and drain the oil into an approved container.

c. Replace oil drain bolt making sure the sealing

washer is in place..

d. With the engine in a level position, fi ll with new

oil. Refer to the table on page 5 for the proper

grade of oil.

NOTE: This engine requires 19 to 20 ounces of oil

if it is completely drained. Use caution when refi lling

the engine as some residual oil may have remained

in the engine. Always use the dipstick when fi lling

the engine with oil to prevent overfi lling.

e. Replace

fi ller plug.

f

Start the engine up and warm it up.

h. After warming up the engine, recheck the oil

level and refi ll as necessary to bring it to the

proper

level.

2. Checking the Oil Level: The oil level must al-

ways be checked before the engine is started. Take

care to remove any dirt or debris from around the

oil fi ll plug before removing. Be sure the oil level is

maintained. Fill to the “FULL” mark on the dipstick.

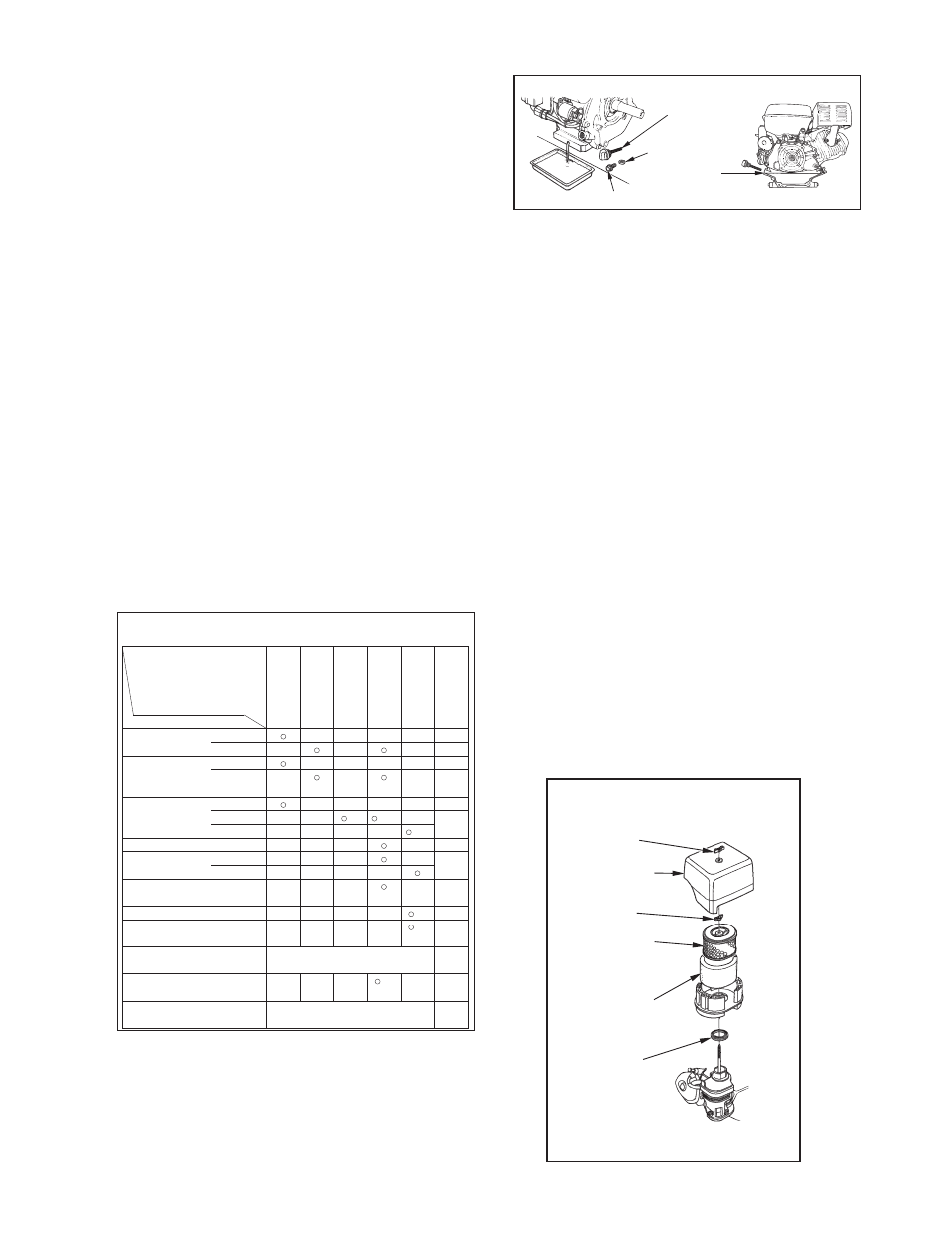

3. Dual Element Air Filter: Clean and/or replace

foam pre-cleaner and air fi lter annually or every 100

hours. Service more often under dusty conditions.

MAINTENANCE SCHEDULE

REGULAR SERVICE PERIOD (3)

ITEM

Perform at every

indicated month or

operating hour interval,

whichever comes first.

Check level

Change

Check level

Change

Check

Clean

Replace

Clean

Check-adjust

Replace

Clean

Check-adjust

Check-adjust

Clean

Clean

Check

Each

Use

First

Month

or

20 Hrs

Every 3

Months

or

50 Hrs

(1)

Every 6

Months

or

100 Hrs

(1)

(2)

Every

Year

or

300 Hrs

(2)

(2)

After every 500 Hrs. (2)

Every 2 years

(Replace if necessary) (2)

Engine oil

Reduction case

oil

(

)

Air filter

Sediment cup

Spark plug

Spark arrester

(

)

Idle speed

Valve clearance

Combustion

chamber

Fuel tank &

filter

Fuel tube

Refer

to

Page

9

9

9

10

10

10

11

12

12

13

13

Shop

manual

Shop

manual

Shop

manual

Shop

manual

applicable types

applicable types

WASHER

OIL LEVEL

DRAIN PLUG

OIL FILLER CAP/

DIPSTICK

GASKET

AIR CLEANER

COVER

PAPER FILTER

ELEMENT

FOAM FILTER

ELEMENT

WING NUT

STANDARD DUAL-FILTER-

ELEMENT TYPE

WING NUT

.

if