Intended uses, Restricted uses, Unit capabilities – Winco W9500HE User Manual

Page 5

Page 3

60706-161

3177-10

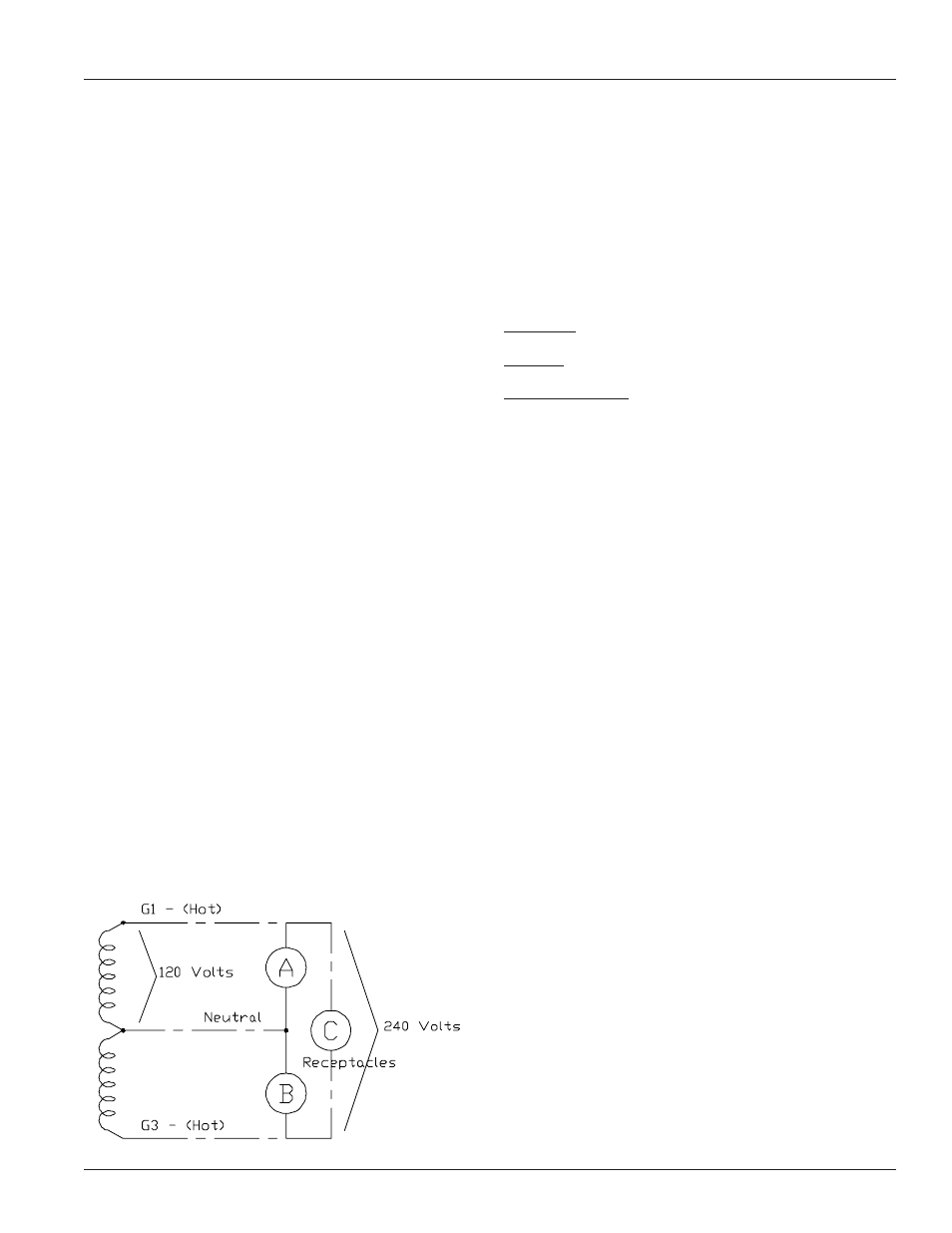

having to choose between powering them or a 240 Volt load.

There are no switches or connectors to change. Simply plug in

and use the power without being concerned about overloading

the generator winding as long as the load doesn't exceed the

size of the generator.

Check the appliance or tool nameplates for the current and

voltage to insure compatibility. Remember that power taken

from receptacle C reduces the power available at both A and

B and vice versa.

Starting Electric Motors

Electric motors require much more current (amps) to start

them than to run them. Some motors, particularly low cost

split-phase motors, are very hard to start and require 5 to 7

times as much current to start them as to run them.

Capacitor motors are easier to start and usually require 2 to 4

times as much current to start them as to run them.

Repulsion Induction motors are the easiest to start and

usually require 1 1/2 to 2 1/2 times as much to start them as

to run them.

Most fractional horsepower motors take about the same

amount of current to run them whether they are of Repulsion-

Induction (RI), Capacitor (Cap), or Split-Phase (SP) type. The

chart below shows the approximate current required to start

and run various types and sizes of 120 volt 60 cycle electric

motors under average load conditions.

RUNNING

STARTING AMPS

HP AMPS

SP

CAP

RI

1/6

3.2

16 TO 22

6 TO 13

5 TO 8

1/4

4.5

22 TO 32

9 TO 18

7 TO 12

1/3

5.2

26 TO 35

10 TO 21

8 TO 17

1/2

7.2

NOT MADE

14 TO 29

11 TO 18

1

13.0 NOT MADE

26 TO 52

20 TO 33

The figures given above are for an average load such as a

blower or fan. If the electric motor is connected to a hard

starting load such as an air compressor, it will require more

starting current. If it is connected to a light load, or no load

such as a power saw, it will require less starting current. The

exact requirement will also vary with the brand or design of

the motor.

Self-excited generators respond to severe overloading

differently than the power line. When overloaded, the engine

is not able to supply enough power to bring the electric motor

up to operating speed. The generator responds with high

initial starting current, but the engine speed drops sharply.

The overload may stall the engine. If allowed to operate at

very low speeds, the electric motor starting winding will burn

out in a short time. The generator winding might also be

damaged.

CAUTION: EQUIPMENT DAMAGE

RUNNING THE GENERATOR SET UNDER THESE

CONDITIONS MAY RESULT IN DAMAGING THE

GENERATOR STATOR AS WELL AS THE MOTOR

WINDING.

Because the heavy surge of current required for starting

motors is required for only an instant, the generator will not

be damaged if it can bring the motor up to speed in a few

seconds of time. If difficulty is experienced in starting motors,

turn all other electrical loads off and if possible reduce the load

on the electric motor.

INTENDED USES

These engine generator sets have been designed primarily

for portable use. Both 120 and 240 volt AC receptacles are

provided in the 'control panel' to plug in your loads (lights,

portable tools, and small appliances). These units are

dual wound generators, therefore the 120 Volt loads must

be equally split with 1/2 of the rated capacity available on

each of the two 120 Volt circuits. See unit capabilities for

further explanation.

These portable units require large quantities of fresh air for

cooling of both the engine and the generator. Fresh air is

drawn from both the engine end and the generator end and

is exhausted at the center of the unit. For safety, long life

and adequate performance, these units should never be

run in small compartments without positive fresh air flow.

RESTRICTED USES

DO NOT remove from the cradle assembly. Removal of the

generator from the cradle assembly may cause excessive

vibration and damage to the engine generator set.

DO NOT install and operate these portable generators in a

small compartment., i.e. generator compartment of

vehicles, motor homes or travel trailers. These

compartments will not allow enough free flow fresh air to

reach the engine generator set for cooling and will cause

the unit to overheat, damaging both the engine and the

generator. Small compartments will also develop hot

spots where there is very little air flow and may cause a fire.

DO NOT attempt to operate at 50 cycles. These units are

designed and governed to operate at 60 Cycles only.

UNIT CAPABILITIES

Generator Connections

The diagram below represents a typical 4000 watt

generator. Receptacles A and B are the two 120 Volt

duplex receptacles. Up to 2000 watts at 120 volts (16.6

Amps) can be taken from the generator at each of the

receptacles. This generator produces 120 and 240 volt, 60

Hz (Hertz), AC (Alternating Current).

The WINCO Industrial series generators have the EXTRA

Heavy FULL POWER winding to allow the use of all the

power available from the engine at either 120 Volts, or 240

Volts or any combination of the 120 or 240 volts. You are

not restricted to splitting up your large 120 Volt loads or