Winco Rotating Armature Design Troubleshooting Guide User Manual

Page 2

60711-020

9089-10

field is grounded and should be repaired or replaced. To

determine which of the fields is grounded, cut the connec

tor between the two coils and retest to determine which

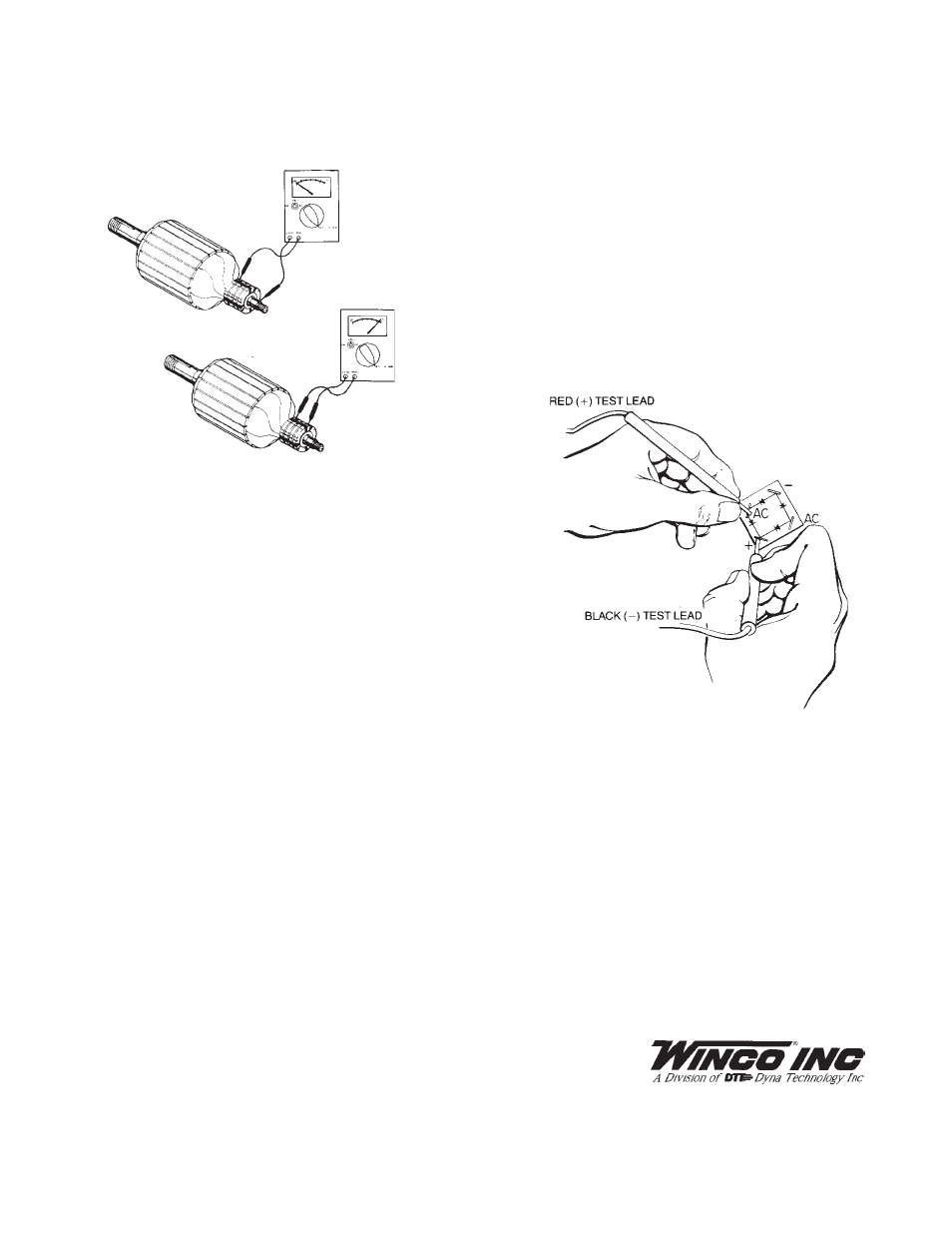

B. Testing the Armature for Opens and Grounds

1. Remove all brushes.

2. Ground fault test - set multimeter to read high resistance

(meg-ohms).Holding one meter lead against a clean spot

on the armature shaft, touch the other lead to each of the

slip rings (one at a time) while observing the meter. If meter

indicates continuity (any reading lower than one meg-

ohm), the armature is grounded. Dirt between the slip rings

and on the insulator surface can cause grounding. If ground-

ing was indicated, carefully clean all dirt off the slip rings and

their insulators and then recheck it. Replace the armature if

it is grounded and unrepairable.

3. Open Test. Set meter to read low resistance (R x 1

ohms). Holding one meter lead on surface of slip ring

No. 1, touch other meter lead to surface of slip ring No.

2 while observing the meter. Meter should indicate

continuity (low resistance - less than one ohm is typical). If

the meter indicates open circuit (infinite resistance) part of

armature winding is open. This may be caused by a

repairable defect in the connection at the slip ring, however

generally an open armature will have to be replaced.

Continue reading the continuity between slip ring No. 2 to

No. 3 and No.2 and No.4. All the slip rings should have

continuity to slip ring number 2, the neutral ring.

NOTE: If these tests have not located the trouble, remove the

armature and have it tested for opens, shorts, and grounds on

a growler.

C. Testing Rectifiers

The field excitation is supplied through a full wave bridge

rectifier. This type of rectifier has four terminals, two AC, a

DC positive and a DC negative.

A rectifier may be tested in the following manner:

1. Disconnect all leads from rectifier.

2. Connect the red ohmmeter lead to the positive DC (+)

terminal.

3. Connect the black lead to each of the AC terminals in turn.

Either a high or low resistance reading will be obtained.

4. Reverse the meter leads, (black lead to the DC POS (+)

and red to the AC terminals, each in turn. An opposite

reading should be observed.

5. Connect the red ohmmeter lead to the negative DC (-)

terminal.

6. Connect the black lead to each of the AC terminals in turn.

Either a high or low resistance reading will be obtained.

7. Reverse the meter leads, (black lead to the DC NEG (-)

and red to the AC terminals, each in turn. An opposite reading

should be observed.

8. Check each terminal to the case. An open circuit (very

high resistance) reading should be observed. A battery pow

ered test light is used. Follow the same procedures described

above. A good diode element will allow current to pass to the

light in the test lamp when the leads are connected in the

forward direction.

9. If the rectifier fails any of the above tests, it should be

considered defective and replaced.

Condenser Testing

Condensers are built into the generator circuit to minimize

radio interference during operation. If a condenser shorts out,

it will also short out the generator output. To determine

whether a condenser is shorted, stop the generator and

disconnect the condenser lead wire from the brush holder.

Using a multimeter on the R x 100 scale, check the resistance

of the condenser. Normal response is a sharp swing of the

meter towards low resistance and then a steady rise towards

high resistance (open circuit). If the capacitor is shorted it will

show as a constant low resistance.

Otherwise, restart the generator without the capacitor connected

to recheck the generator for output. If the generator then

provides power, the condenser was at fault and should be

replaced. (If the generator doesn't provide power, the problem

was not caused by that condenser, reconnect the lead wire).

225 South Cordova Avenue

Le Center, Minnesota 56057

507-357-6821