Troubleshooting – VACUUBRAND MZ 2 VARIO-SP User Manual

Page 36

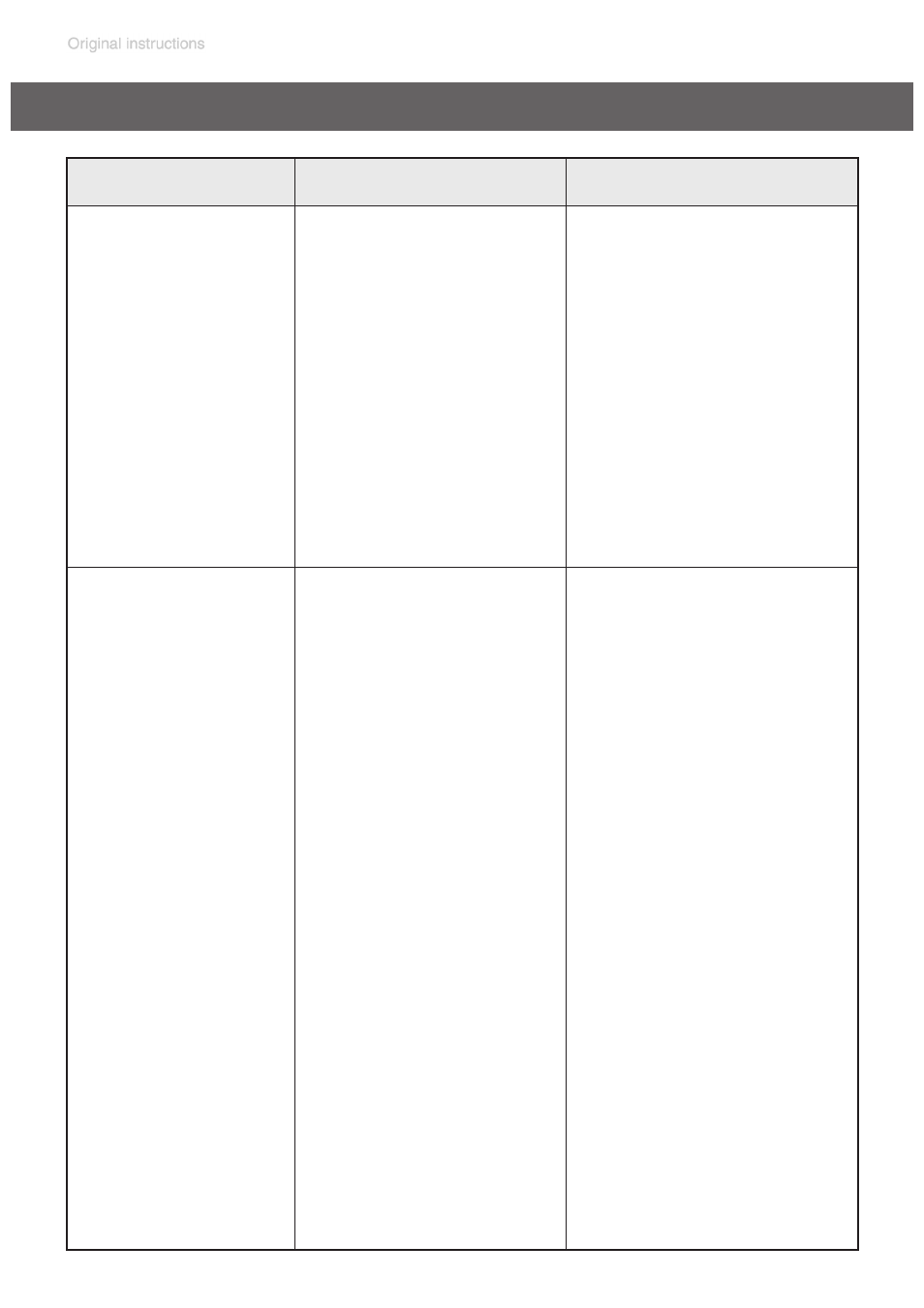

Fault

Possible cause

Remedy

❑ Pump does not

start or stops im-

mediately.

➨ Supply voltage is miss-

ing or is too low?

✔ Check or connect electri-

cal supply voltage.

➨ Control signal for motor

speed is missing?

✔ Check control signal.

➨ Overpressure in outlet

line?

✔ Remove blockage in line,

open valve, or reduce

overpressure.

➨ Motor overloaded?

✔ Allow motor to cool down,

identify and eliminate

cause of failure. Manual

reset is necessary. Sepa-

rate pump from supply

voltage.

❑ Pump does not

achieve its ultimate

vacuum or usual

pumping speed.

➨ Centring ring at small

flange connection not

correctly positioned, or

leak in the pipeline or

vacuum system?

✔ Check pump directly -

connect vacuum gauge

directly at pump inlet -

then check connection,

pipeline and vacuum

system if necessary.

➨ Long, narrow vacuum

line?

✔ Use lines with larger di-

ameter, length as short as

possible.

➨ Pump has been ex-

posed to condensate?

✔ Allow pump to run for

some minutes with atmo-

spheric pressure at the

inlet to purge.

➨ Deposits have been

formed inside the

pump?

✔ Clean and inspect the

pump heads.

➨ Diaphragms or valves

damaged?

✔ Replace diaphragms and/

or valves.

➨ Outgassing substances

or vapor generated in

the process?

✔ Check process parame-

ters.

➨ Pump temperature

too high (motor speed

reduced or pump

switched off)?

✔ Ensure sufficient cooling

of the pump or reduce

inlet pressure. Separate

pump from supply volt-

age if the pump has been

switched off.

Troubleshooting