Troubleshooting – VACUUBRAND PC 3001 basic User Manual

Page 15

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999198 / 29/09/2009

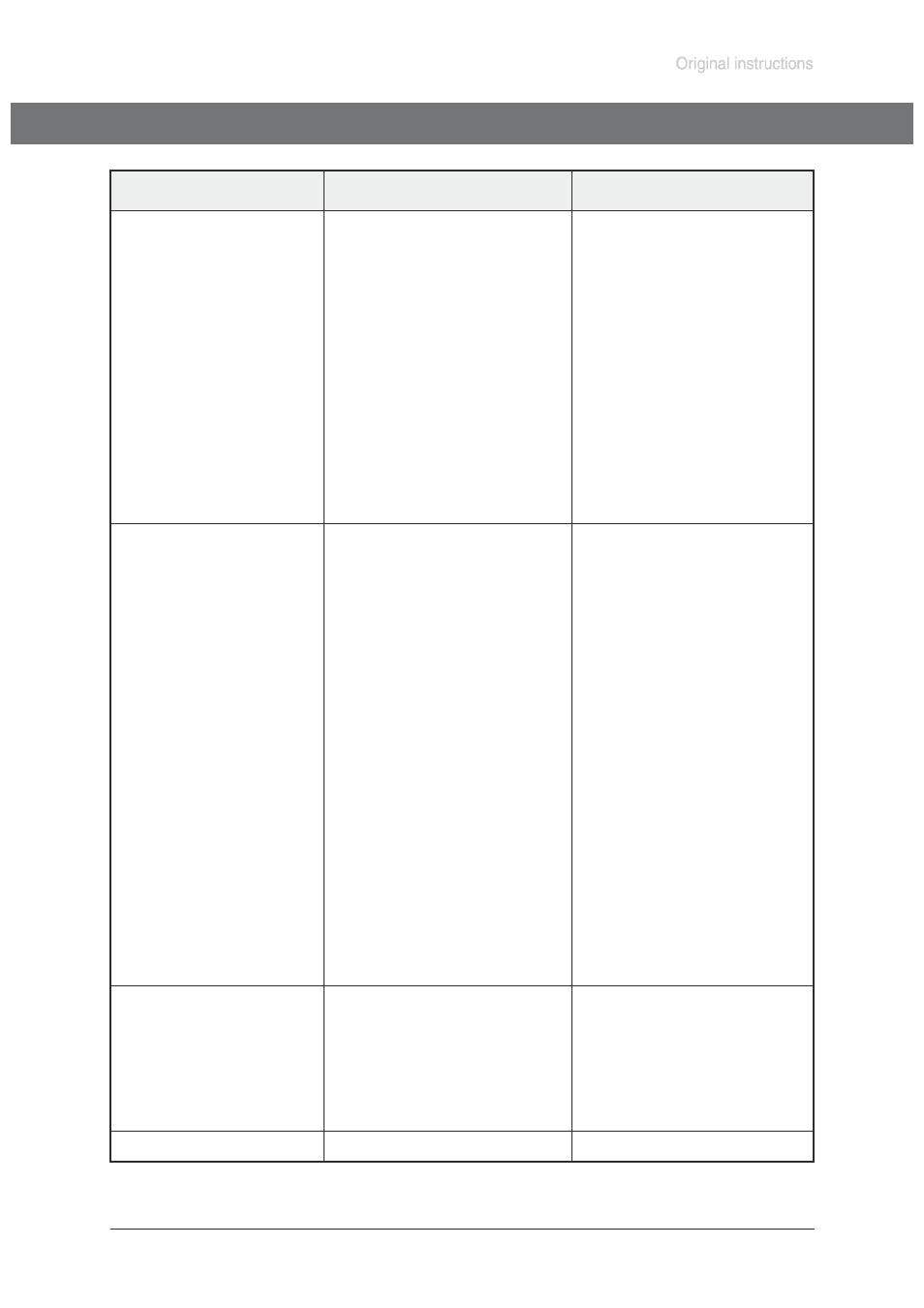

Troubleshooting

Fault

Possible cause

Remedy

❑ Pump does not start or

stops immediately.

➨ Knob for motor speed is

turned to the left stop?

✔ Turn the knob to the right.

➨ Supply voltage is missing or

too low?

✔ Check or connect the supply

voltage; check the mains

fuse.

➨ Overpressure in the exhaust

line?

✔ Open exhaust line, ensure a

free (pressureless) outlet line

➨ Motor overloaded?

✔ Allow motor to cool. Identify

and eliminate the cause of

failure.

➨ VACUU•BUS fuse has been

triggered, e.g. load in the

VACUU•BUS system too high

or short circuit in valves?

✔ Remove VACUU•BUS com-

ponents (e.g. valves). The

fuse is self-resetting.

❑ Pump does not achieve

ultimate vacuum or nor-

mal pumping speed.

➨ Centring ring at a small flange

connection not correctly posi-

tioned or leak in the pipeline

or vacuum system?

✔ Check pump directly - con-

nect vacuum gauge directly

at pump inlet - then check

connection, pipeline and

vacuum system if necessary.

➨ Long, narrow vacuum line?

✔ Use lines with larger dia-

meter, length as short as

possible.

➨ Pump has been exposed to

condensate?

✔ Allow pump to run for some

minutes with atmospheric

pressure at the inlet.

➨ Deposits have been formed

inside the pump?

✔ Clean and inspect the pump

heads.

➨ Diaphragms or valves defec-

tive?

✔ Replace diaphragms and/or

valves.

➨ Outgassing substances or

vapour generated in the pro-

cess?

✔ Check process parameters.

➨ Pump temperature too high

(reduced motor speed)?

✔ Ensure sufficient cooling

of the pump or reduce inlet

pressure.

❑ Pump too noisy.

➨ Loud exhaust noise?

✔ Connect hose or silencer to

pump outlet.

➨ Diaphragm crack or dia-

phragm clamping disc loose?

✔ Perform maintenance.

➨ Other than above mentioned

causes?

✔ Contact local distributor.

❑ Pump seized.

✔ Contact local distributor.