During operation – VACUUBRAND HP 63B2 User Manual

Page 15

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check carefully

the validity of this document with respect to his product. Manual-no.: 999069 / 24/09/2014

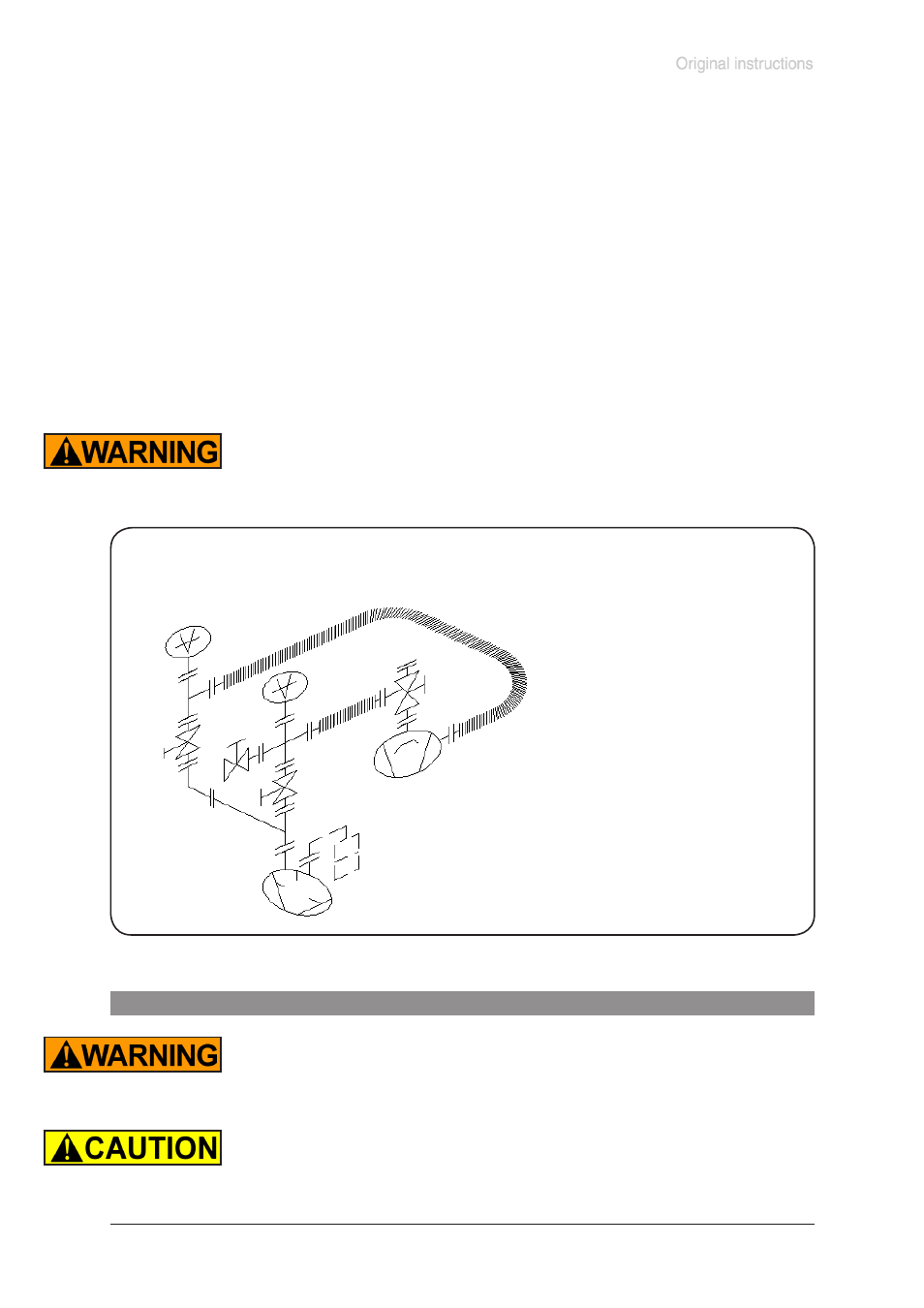

Vacuum connection diagram:

P1

Backing pump

P2

Diffusion pump

V1

Fore-vacuum valve

V2

By-pass valve

V3

High vacuum valve

V4

Venting valve

M1

Measuring point 1

M2

Measuring point 2

F0

Oil mist filter

V1

V2

V3

V4

M1

M2

F0

P1

P2

Venting the vacuum vessel

➨

Close high vacuum valve (V3).

➨

Close by-pass valve (V2) (if not closed).

➨

Open venting valve (V4).

Pumping down again

➨

Close venting valve (V4).

➨

Close fore-vacuum valve (V1).

➨

Open by-pass valve (V2).

➨

Close by-pass valve (V2) once the pressure inside the vacuum vessel is below

0.1 mbar.

➨

Open fore-vacuum valve (V1).

➨

Open high vacuum valve (V3).

+

Note: If the fore-vacuum (M1) rises above 0.1 mbar, close the high vacuum valve

(V3) and pump down with the backing pump to a pressure below 0.1 mbar.

+

If the thermal cutout of the rotary vane pump has tripped, it is imperative

that the high vacuum valve (V3) be closed and the diffusion pump switched

off!

During operation

+

Maximum ambient temperature: 40 °C

Check the maximum temperatures, if installing the pump in a cabinet or a housing.

Make sure ventilation is adequate, especially if the ambient temperature is el-

evated.

• Check the oil level of the rotary vane pump and the pump fluid level of the diffu-

sion pump every time before starting the pump, however at least once a week.

Check the oil and pump fluid levels more frequently if high amounts of gas or

vapor are pumped.