Traxxas 41094-1 User Manual

Page 14

14

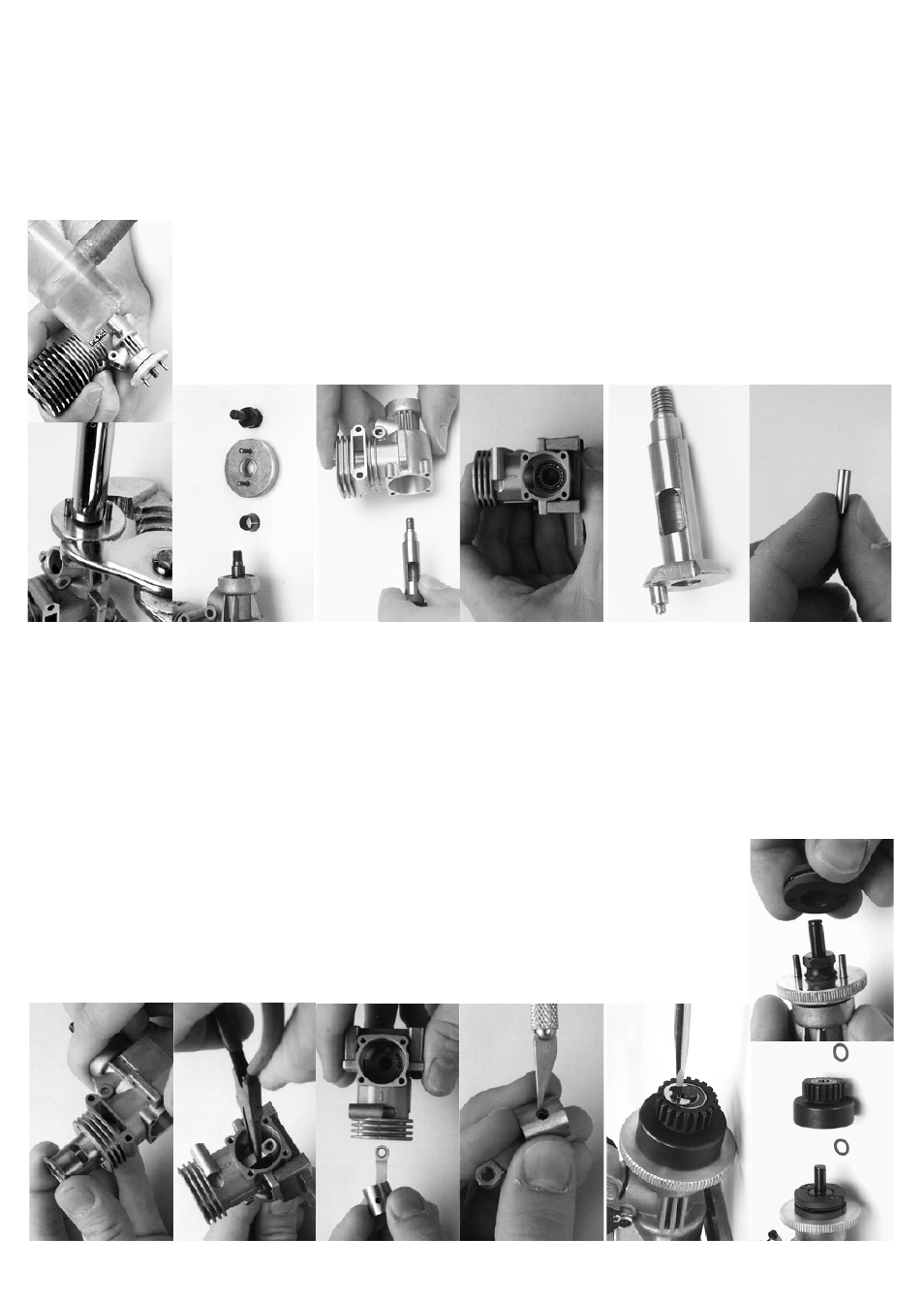

STEP

15:

Remove the connecting

rod and piston through the top

of the crankcase.

STEP

16:

To remove the connecting rod from the piston, use a s

har

p-

point

ed t

ool t

o r

em

ov

e t

he s

mall m

et

al

G-clip in the side of

the piston. Do not re-use the old

G-clip. When installing

a new conne

cting rod, use the

supplied

new G-clip.

STEP

21:

Remove the crankshaft by pulling

it straight out of the

crankcase.

STEP

22:

The bearings are press-fit into the crankcase. To remove them, the crankcase

must be heated

with a

heat

gun or torch. The crankcase

will

expand

with

heat and release

the bearings.

To avoid the possibility

of

burns or other damage, do not attempt

to

remove

the bearin

gs. Clea

n the bearings

by flushing

them

with dena

tured alcohol and then place one or two

drops of after-run oil on the races.

STEP

23:

Before

installing

a

new

connecting

rod,

you

can

increase connecting rod life by

polish

ing the

crankshaft

journal. Use 1200 grit sandpaper to remove the

surface scratches followed

by liqui

d metal polish

to

buff the crankshaft journal

to a bright, smooth shine.

Rinse

thoroughly

with denatured

alcohol.

Lube

with

after-run oil.

STEP

24:

Use the 1200 grit sandpaper

and

the liquid metal

polish

on the wrist pin

also. Rinse

thoroughly

with

denatured alcohol

and lube with after-run oil.

STEP

13:

Pull the sleeve straight up and out of

the crankcase. If

the sleeve will not move, rotate the crankshaft until the sleeve pushes up.

STEP

14:

Rotate the crankshaft

to

bottom dead center. Lightly

grab the

connectin

g

rod with a

pair of

needlenose

pliers and gently pull it off

of the crankshaft journal.

Removing the clutch and

flywheel

STEP

17:

It is not necessar

y to remove

the clutch assembly

unless

you are

servicing

the clutch, crankshaft, or

engine

bearings. Use the tip of a small screwdriver

to

remove the E-clip that holds the clutch bell gear.

STEP

18:

Remove

the clutch bell

gear

and the clutch shoes.

Note that there are two 5x8mm PTFE washers,

one

on each side of the clutch bell

gear. Check the clutch

shoes for

excessive wear

or

cracking around

the

pin

holes. If

the

clutch

shoes

are worn

to

the point that

the clutch

spring contacts

the

clut

ch

bell,

then

the

shoes must

be replaced.

STEP

19:

Grip the flywheel with a

pair of

pliers (locking pliers

work best). Remove the

clutch adapter nut with a 10mm

deep

socket.

Hold

the engin

e

just above your

workbench and tap the

flywheel from behi

nd with a

non-marring

hammer (plastic or wood). Several easy

blows

may be necessary to release

the flywheel

and

split beveled cone.

STEP

20:

The flywheel

and

the split-beveled

cone should pull

smoothly

off

of the crankshaft.