Sigtronics Sport 200 S Installation Instructions User Manual

Sigtronics sport 200 s installation instructions, Specialists in “sound” management

Sigtronics Sport 200 S Installation Instructions

Specialists in “SOUND” Management

178 East Arrow Highway, San Dimas, CA 91773 ( 909 ) 305-9399

INTRODUCTION

ATTENTION INSTALLER: To assure a trouble free installation,

please read the entire instructions through once before

beginning.

Sport 200 S SYSTEM SPECIFICATIONS

C

ONFIGURATION – The Sigtronics Sport 200 S Intercom system is

specifically designed for permanent, panel mounted installation in

aircraft. The Sport 200 S provides voice activated (VOX) intercom, a

Push-to-intercom mode for applications where voice activated (VOX)

intercom operation is not desired, and music input for two headset

positions in a small single chassis unit.

STEREO MUSIC INPUT – Music input accepts standard portable music

headphone or line level outputs. Automobile Speaker level outputs can

be adapted for use with Sport 200 S systems.

COMPATIBILITY – Sigtronics Sport 200 S intercoms have been

designed to operate with all standard general aviation aircraft radios

and headsets.

SIZE: Panel 1” x 2.5”. Chassis - 1” high x 2.5” wide x 4” deep. Can be

mounted either horizontally or vertically in the aircraft panel.

WEIGHT: 5.5 ounces (Sport 200 S intercom unit with panel and knobs).

Jacks and wiring harness weigh 6.0 ounces

INPUT POWER: 11VDC through 32VDC. Maximum current drain 0.11

Amps

DISTORTION: Less than 1% total harmonic distortion.

WARRANTY: Sport 200 S intercoms are constructed of high quality

components and carry a five year parts and labor warranty.

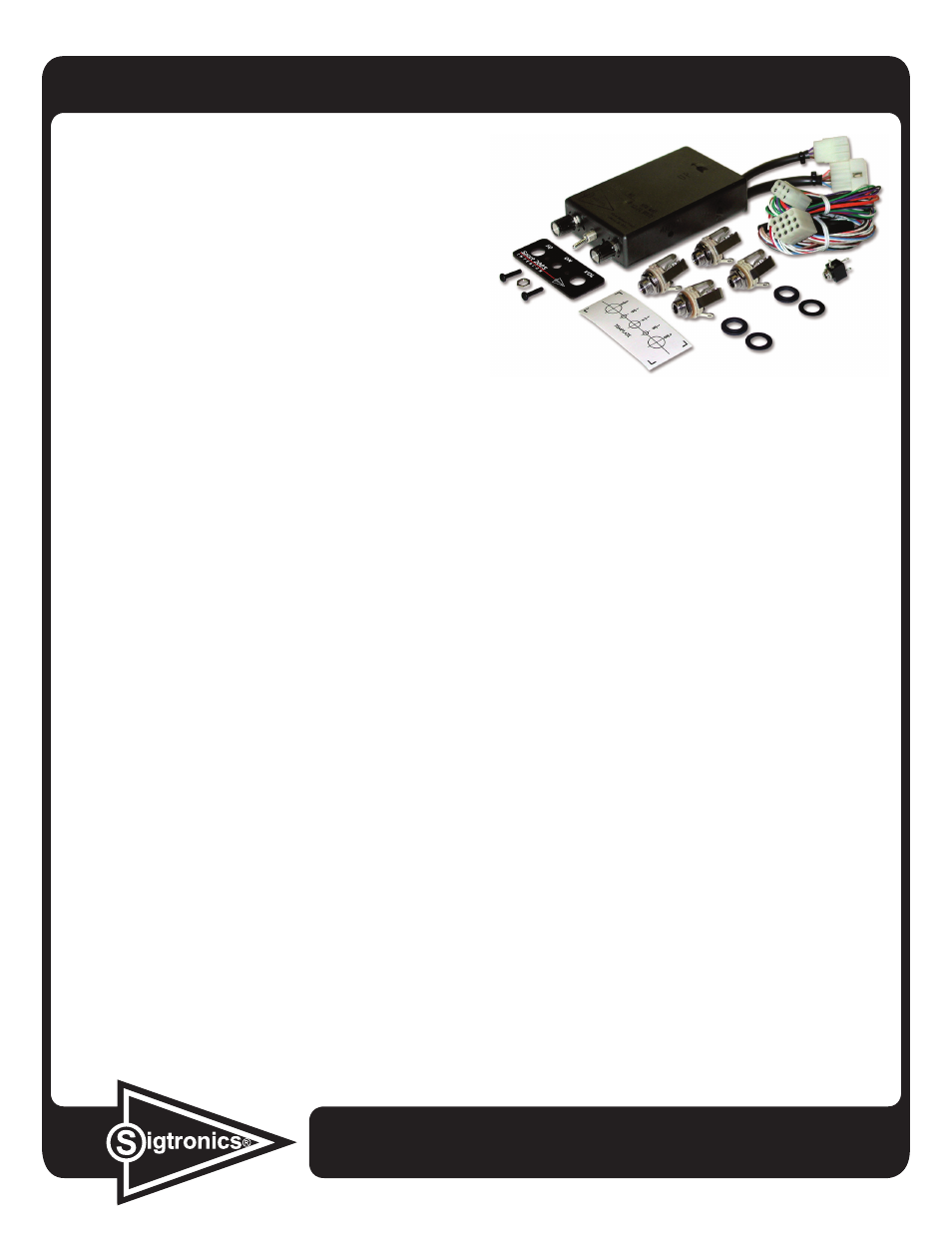

HARDWARE SUPPLIED

Besides the intercom unit and instructions, each Sport 200 S system

comes with the following hardware:

Headphone Output Jacks - Accept standard 0.250” aircraft

stereo or monaural headphone plugs. .................................................2

Microphone Input Jacks - Accept standard 0.206” aircraft

microphone plugs. (U93 plug compatible jacks can be used in

place of the jacks provided – monaural installations only). ..........2

Mic Jack Insulating Washers, Flat ............................................................2

Mic Jack Insulating Washers, Shoulder .................................................2

Intercom Panel - lettered on both sides. ..............................................1

Intercom Control Knobs .............................................................................2

Mounting Screws 4-40 x 1/2 .....................................................................2

Drill Template - Adhesive backed hole size pattern for

drilling aircraft panel. ..................................................................................1

Intercom/Aircraft Interface Cable (4 feet long) .................................1

Headphone/Music Interface Cable (4 feet long) ...............................1

Stereo music input jack 3.5mm ...............................................................1

MUSIC MUTE OPTIONS

FACTORY DEFAULT - PARTIAL MUSIC MUTE DURING ICS - When

listening to music and someone speaks on the intercom the default

factory operation is to partially mute the music so you can hear the

conversation. The Sport 200 S intercoms have one additional option

that can be enabled if desired. This option is enabled with the intercom

removed from the aircraft.

FULL MUSIC MUTE DURING ICS OPTION - The music can be

completely muted during intercom conversations. To enable this

option, small jumper wires are installed on the solder side of the

circuit board.

CHASSIS INSTALLATION

UNIT PLACEMENT

The Sport 200 S unit has been designed to mount either horizontally

or vertically in your aircraft panel. The location selected for the Sport

200 S unit requires a minimum front panel area of 2 1/2” by 1”. Depth

required behind panel is 4” plus cable access.

CAUTION: Move the aircraft flight controls through the limits of travel

while observing the selected area and making sure that the rear of

the intercom and cable will not interfere with any aircraft control

components.

PANEL PREPARATION:

1. Position the adhesive drill template on the aircraft panel in the

selected area.

2. Center punch each hole at the cross lines. (Five holes are in a straight

line and equally spaced 0.4” apart)

3. Drill 1/8” pilot holes in all five places.

4. Enlarge holes to 1/4” and 3/8” per the template.

MOUNTING CHASSIS (See Figure 2)

1. Remove the knobs from the Volume and Squelch controls using a

0.050” Allen wrench. Remove the nut from the ON/OFF switch. NOTE:

DO NOT REMOVE the nuts from the Volume and Squelch controls.