Spa-400n installation drawing figure 4 – Sigtronics SPA-400N User Manual

Page 2

MOUNTING CHASSIS (continued)

5. Install panel and lightly thread nut on to ON-OFF switch. Nuts and

washers on Volume and Squelch controls should fit inside the 3/8”

diameter holes.

6. Select two 4-40 screws through holes in intercom panel. Tighten ON-

OFF switch nut.

7. Install knobs on Volume (VOL) and Squelch (SQ) control shafts using

.050” Allen wrench.

MOUNTING HEADPHONE AND MICROPHONE JACKS:

1. Select mounting areas. (One mic and one headphone jack for each

headset). Again, make sure the jacks will not interfere with aircraft

control components.

2. Drill 3/8” diameter holes for headphone jacks and install.

3. Drill 1/2” diameter holes for mic jacks and install with insulating

washers supplied. (See Figure 3).

WIRING INSTRUCTIONS

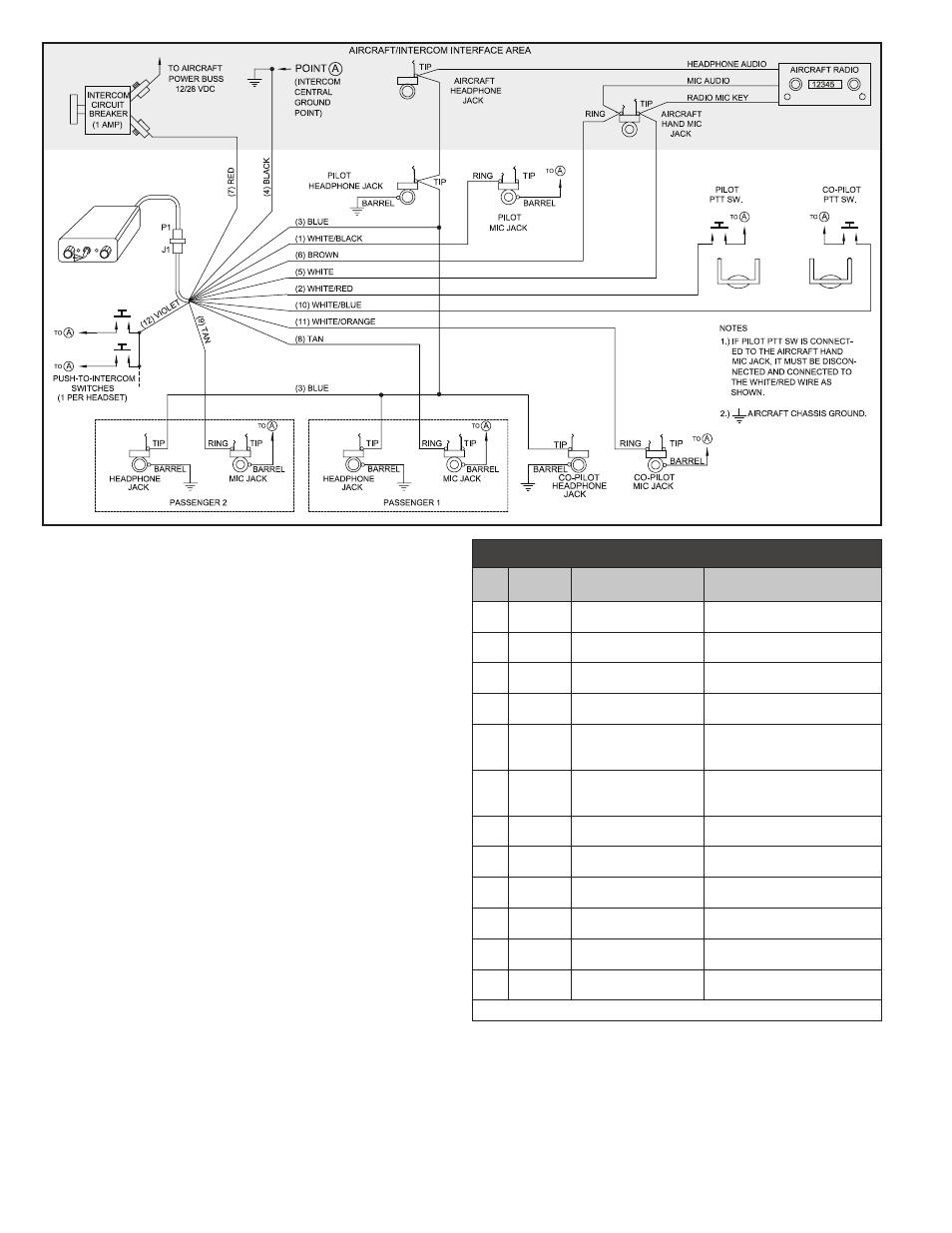

Connections should be made as shown in Figure 4 and indicated in Table 1

*A. White / red (pilot push-to-talk) must correspond with white / black (pilot

mic input) as shown.

*B. The blue wire from Pin 3 must be connected to the aircraft radio

headphone output- NOT the speaker output.

*C. Connect all intercom mic jack grounds to Point A as shown in Figure

4. (Use black washers supplied to insulate intercom mic jacks from

aircraft chassis ground).

*D. Do NOT connect transmit switches to white (key) wire.

*E. Red wire may be connected to either 12 (14V) or 24 (28V) power

source. No switching or adjustments are required to operate from

either source.

*F. Tan wires from Pins 8 and 9 are only used on 4-way installations.

FINAL CHECKOUT AND ADJUSTMENT

After the unit is installed, again check that the intercom chassis, jacks,

and wiring harness are clear of all aircraft operating controls and cause

no interference with them. Check out the intercom functions by following

the Operating Instructions.

It may be necessary at this time to adjust the intercom mic output to

the aircraft radios. A small, square, adjustable trimmer potentiometer is

provided inside the unit for this purpose. It is accessible through a hole

in the side of the case, marked “Mod. Adj.”, and can be adjusted with a

screwdriver. In the event of over modulation (garbled) or reports of weak

transmissions over the aircraft radio, an appropriate adjustment can be

made. Clockwise rotation increases the output level to the aircraft radio

mic input. Counter-clockwise rotation decreases modulation level. This

adjustment sometimes needs to be made after initial installation of the

intercom or if a new radio is installed. (The output is set for unity gain at

Sigtronics.)

Weight: Intercom with panel and knobs (4.5 oz.)

Jacks and wiring harness (5.5 oz. maximum)

Current Draw: 0.06 amps @ 28 volts

FAA TSO: C50b ENV. CAT (DO-160) CFBBBX

INTERCOM SPA-400

SQ

ON

VOL

SPA-400N

INTERCOM

Table 1

Plug

Pin #

Wire Color

Function

Connect To:

1

White /

Black

Pilot Mic Input

Ring Terminal of Pilot Intercom

Mic Input Jack

2

White /

Red *A

Pilot Transmit Switch Input

Pilot Transmit Switch (PTT)

(Switch to Ground to Transmit)

3

Blue *B

Headphone - Radio and

Intercom Outputs

Radio Headphone Output and all

Headphone Jacks

4

Black *C

Ground

Hand Mic Jack Ground Terminal

(Point A)

5

White *D

Transmit Relay (Key)

Control Output

Tip Terminal of Aircraft Mic Jack or

Key Input of Aircraft Radio or Audio

Panel

6

Brown

Mic Audio Output

Ring Terminal of Aircraft Mic Jack or

Input of Aircraft Radio

or Audio Panel

7

Red *E

12 VDC through 24 VDC

Power Input

Intercom Circuit Breaker

8

Tan *F

Passenger #1 Mic Input

Ring Terminal of Passenger #1

Mic Jack

9

Tan *F

Passenger #2 Mic Input

Ring Terminal of Passenger #2

Mic Jack

10

White /

Blue

Copilot Transmit Switch

Copilot Transmit Switch (PTT)

11

White /

Orange

Copilot Mic Input

Ring Terminal of Intercom Copilot

Mic Input Jack

12

Violet

Push to Intercom Input

Push to Intercom Switches

* See Wiring Instructions

SPA-400N Installation Drawing

Figure 4

spa-400n.pdf 1-8-2007 Form SPA-400N-IS REV E