Adjusting chart, Subsequent readjustment, Hex key needle adjustment – O.S. Engines 60B Carb - 27981010 User Manual

Page 2: Cleanliness, Parts list

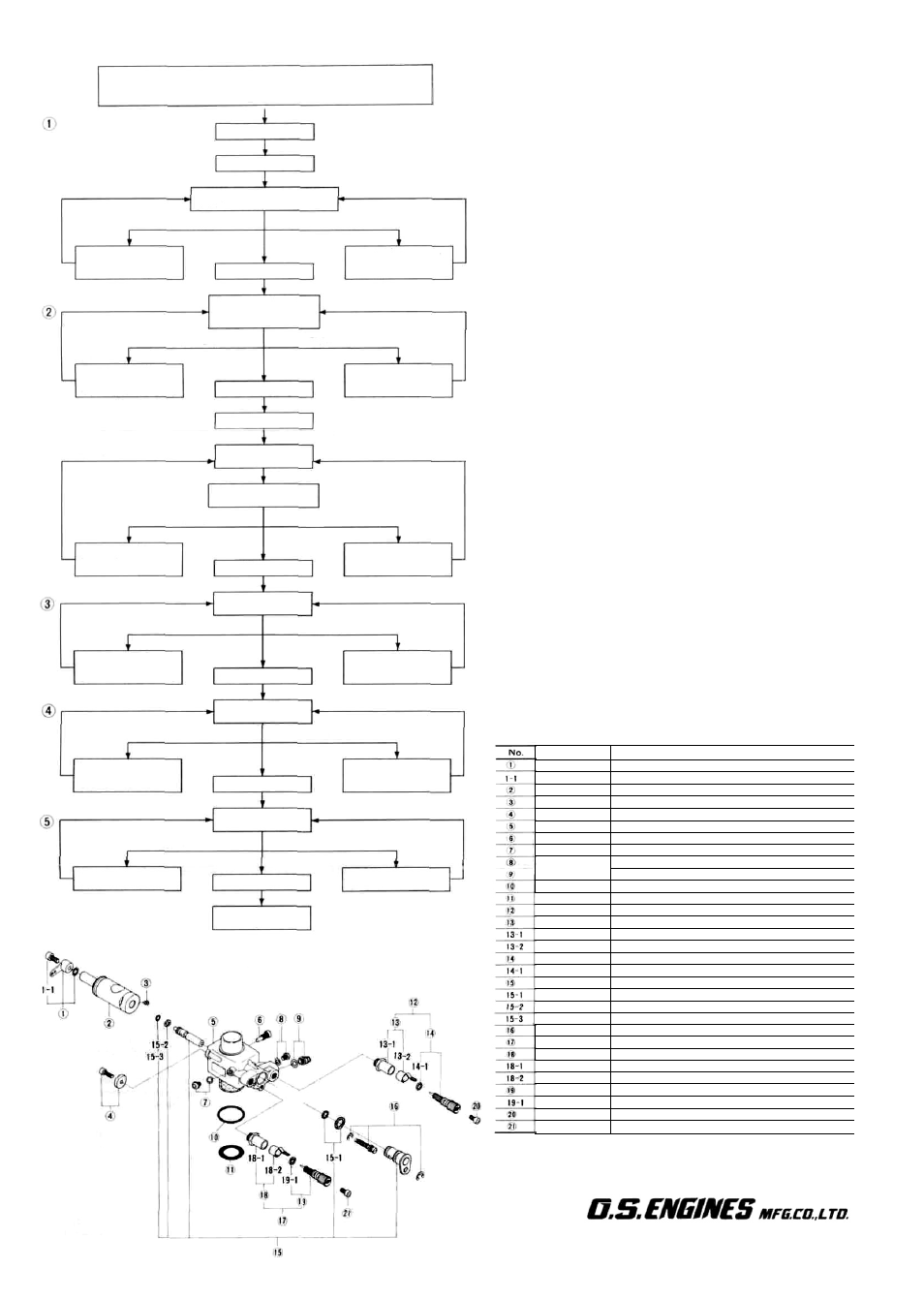

ADJUSTING CHART

High Speed Needle Valve—2 turns opened from fully closed position.

Medium Speed Needle Valve—1 turn opened from fully closed position

Idle Mixture Control S c r e w — 2 turns open from fully closed position

Start the engine

Warm up the engine

Medium Speed Needle Valve gradually until the optimum

hovering performance is obtained.

Note: It is NOT necessary to open the Medium Speed Needle Valve

if symptoms of lean running at hovering speeds remain

unconfirmed.

SUBSEQUENT READJUSTMENT

Once the engine has been run-in (see engine instructions) and the

carburettor controls properly set up, it should be unnecessary to

alter the mixture settings, except to make minor changes to the

Main (High-Speed) Needle Valve, occasionally, to take account

of differences in climatic conditions.

However, as previously mentioned, the use of a different fuel,

particularly one containing more, or less, nitromethane and/or

a different type or proportion of lubricating oil, is likely to call

for some modification to the High-Speed Needle Valve adjust-

ment. As a safety measure, it is advisable to increase the High-

speed Needle Valve setting by an extra half-turn counter-

clockwise prior to establishing the new setting. The same applies

if the silencer type is changed. A different silencer may alter the

exhaust pressure applied to the fuel feed and call for a revised

Needle-Valve setting.

The use of a different glowplug, or changes to the main rotor and

its pitch angles may also require compensating carburettor

readjustments.

HEX KEY NEEDLE ADJUSTMENT

The knurled heads of the two needle valves (High-speed and

Medium Speed) are provided with diagonal slots for use with a

s c r e w d r i v e r A l t e r n a t i v e l y for more positive location via an Allen

hexagonal key, these heads also have M2.6 internal threads, "into

which M2.6 x 6mm Allen cap-head screws may be fitted. To avoid

risk of damage to the fuel passages when tightening these screws,

remove the needle valves from the carburettor and use 'Loctite'

thread-lock compound to secure the screws.

CLEANLINESS

The minute particles of foreign matter that are invariably present

in any fuel, may result in a carburettor malfunction; most

commonly, restricted fuel flow, which may cause the engine to

cut out in flight, or to run lean, overheat and probably become

damaged. Be sure to use a good filter between your refuelling

container and the model's fuel tank.

O.S. 'Super-Filters' (large and small) are available as optional

extras. One of these, fitted to the outlet pipe inside your

refuelling container, will prevent the entry of foreign matter into

the fuel tank.

To clean the outside of the carburettor, use methyl-alcohol

(methanol) or glow fuel. Do not use gasoline, kerosene or other

petroleum based materials which may cause the silicone rubber

seals in the carburettor to swell and deteriorate.

PARTS LIST

Code No.

27381400

22826131

27981200

27981920

27981220

27981100

27981600

27881120

27881120

22681953

27915000

27915100

27981900

27381940

27381941

26711305

27981910

24981837

27981300

27981850

27881820

22781800

27981332

27981900

27381940

27381941

26711305

27981910

24981837

41621000

41621000

Description

Throttle Lever Assembly (w/Screw & Washer)

Throttle Lever Fixing Screw

Carburettor Rotor

Metering Nozzle Fixing Screw

Rotor Guide Washer (w/Fitting Screw)

Carburettor Body

Fixed Throttle Stop Screw

Plug Screw (w/Gasket)

Plug Screw (w/Gasket)

Fuel Inlet (w/Gasket)

Carburettor Rubber Gasket

Carburettor Sealing Washer

Needle Valve Assembly

Needle Valve Holder Assembly

Needle Valve Holder

Ratchet Spring

Needle (w/"0" Ring)

"0" Ring

Mixture Control Valve Assembly

"0" Ring Set

"0" Ring (L)

"0" Ring (S)

Mixture Control Screw (w/Retainer)

Needle Valve Assembly

Needle Valve Holder Assembly

Needle Valve Holder

Ratchet Spring

Needle (w/"0- Ring)

"0" Ring

Screw for Needle

Screw for Needle

The specifications are subject to alteration for improvement without notice

6-15 3-chome Imagawa Higashisumiyoshi-ku

Osaka 546, Japan. TEL (06) 702-0225

FAX. (06) 704-2722

Observe the mixture condition

while "floating" the model

Rich mixture

Lean mixture

Turn the Idle Mixture

Control Screw

counter-clockwise

Idling OK

Turn the Idle Mixture

Control Screw

clockwise

Observe the hovering

mixture condition

(Throttle response)

Lean mixture

Rich mixture

Close the High Speed

Needle Valve

(Turn clockwise)

Hovering OK

Open the High Speed

Needle Valve

(Turn counter-clockwise)

Land the model

Idle for approx:

10 seconds

Observe the transition

("Float" the model)

Lean mixture

Rich mixture

Turn the Idle Mixture

Control Screw

counter-clockwise

Idling OK

Turn the Idle Mixture

Control Screw

clockwise

High Speed Flight

Lean mixture

Rich mixture

Close the High Speed

Needle Valve

(Turn clockwise)

High speed flight OK

Open the High Speed

Needle Valve

(Turn counter-clockwise)

Lean mixture

Rich mixture

Turn the Idle Mixture

Control Screw

clockwise

Idling OK

Turn the Idle Mixture

Control Screw

counter-clockwise

Fine tuning of

idling mixture

Fine tuning of

hoverinq mixture

Rich mixture

Close the Medium

Speed Needle Valve

Hovering OK

Adjustment

completed

Open the Medium

Speed Needle Valve

Lean mixture

©Copyright 1992 by O.S. Engines Mfg. Co., Ltd. All rights reserved. Printed in Japan. 60130260-19706