O.S. Engines 20B Carb - 23818030 User Manual

O.S. Engines Hardware

INSTRUCTIONS FOR O.S. TYPE 20A & 20B AUTOMATIC CARBURETTORS

These slide-throttle carburettors have been designed expressly for O.S. racing car engines. They release the

full potential of these engines, providing instant throttle response, rapid acceleration and high peak power

output.

The shank of the carburettor is fitted with an insulating sleeve of engineering plastic to minimize the trans-

mission of heat from the crankcase to the carburettor body. This prevents excessive pre-heating of the incom-

ing charge and maintains steady running characteristics with rapid deceleration, as well as instant acceleration

and maximum power output.

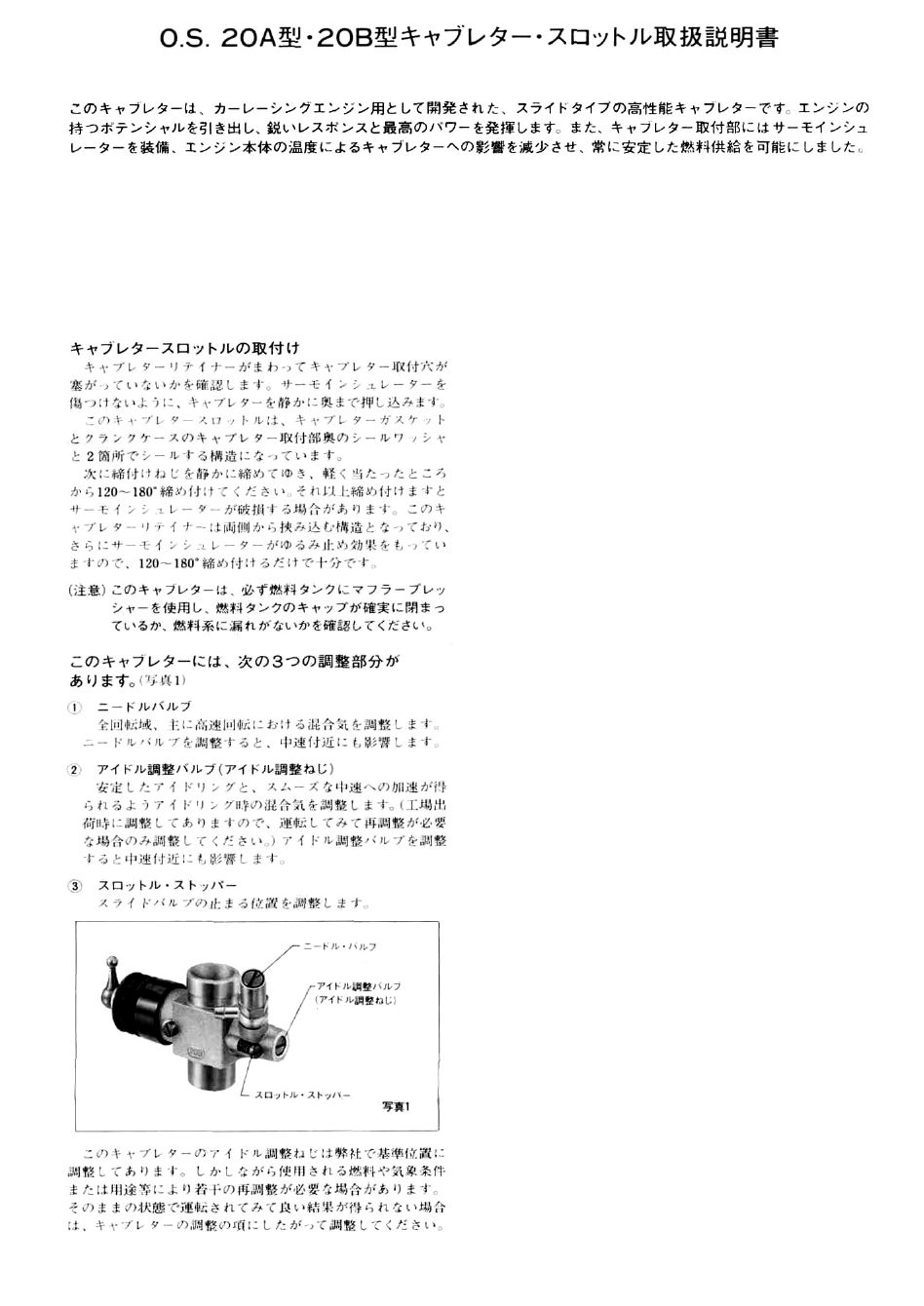

Mixture Control Valve

(Mixture Control Screw)

Throttle Stop Screw

Photo1

When supplied with the engine, the carburettor is

fitted loosely in the intake boss. Secure it in the

following manner.

1. Loosen the carburettor retainer screw and rotate

the carburettor to its proper position in the intake

boss.

2. The carburettor is aligned vertically and sealed

against air leaks by a sealing washer in the bottom

of the intake boss and by a heatproof rubber

gasket between the carburettor body and the rim

of the intake boss. Therefore, press the carburettor

firmly down into the intake boss while rotating

the retainer screw. Rotate the screw gently until

it stops, then tighten a further 120~180°.

Note: The two-piece retainer is designed to pinch the

carburettor from both sides and the insulating

sleeve effectively prevents the assembly from

vibrating loose.

Warning! Do not over-tighten the retainer screw as

this will damage the insulator.

Important: These carburettors require muffler pres-

surized fuel feed. Make sure that the fuel

tank is completely sealed when filled and

that there are no leaks in the pressure line

or delivery pipe.

ADJUSTING THE CARBURETTOR

Three adjustable controls are provided on this carbuettor.

• The Needle Valve:

When set to produce maximum power at full

throttle, this establishes the basic fuel/air mixture

strength, which is then maintained by the carbu-

rettor's automatic mixture control system to cover

the engine's requirements at reduced throttle set-

tings.

• The Mixture Control Valve (Mixture Control

Screw):

For adjusting the mixture strength at part-throttle

and idling speeds, to obtain steady idling and

smooth acceleration to medium speeds. The Mix-

ture Control Valve has been factory set for the

approximate best result. First, run the engine as

received, and re-adjust the Mixture Control Valve

only when necessary.

• The Throttle Stop Screw:

For setting the position where the carburettor

rotor is closed.

Needle Valve