O.S. Engines 8AA Carb - 29383000 User Manual

Page 2

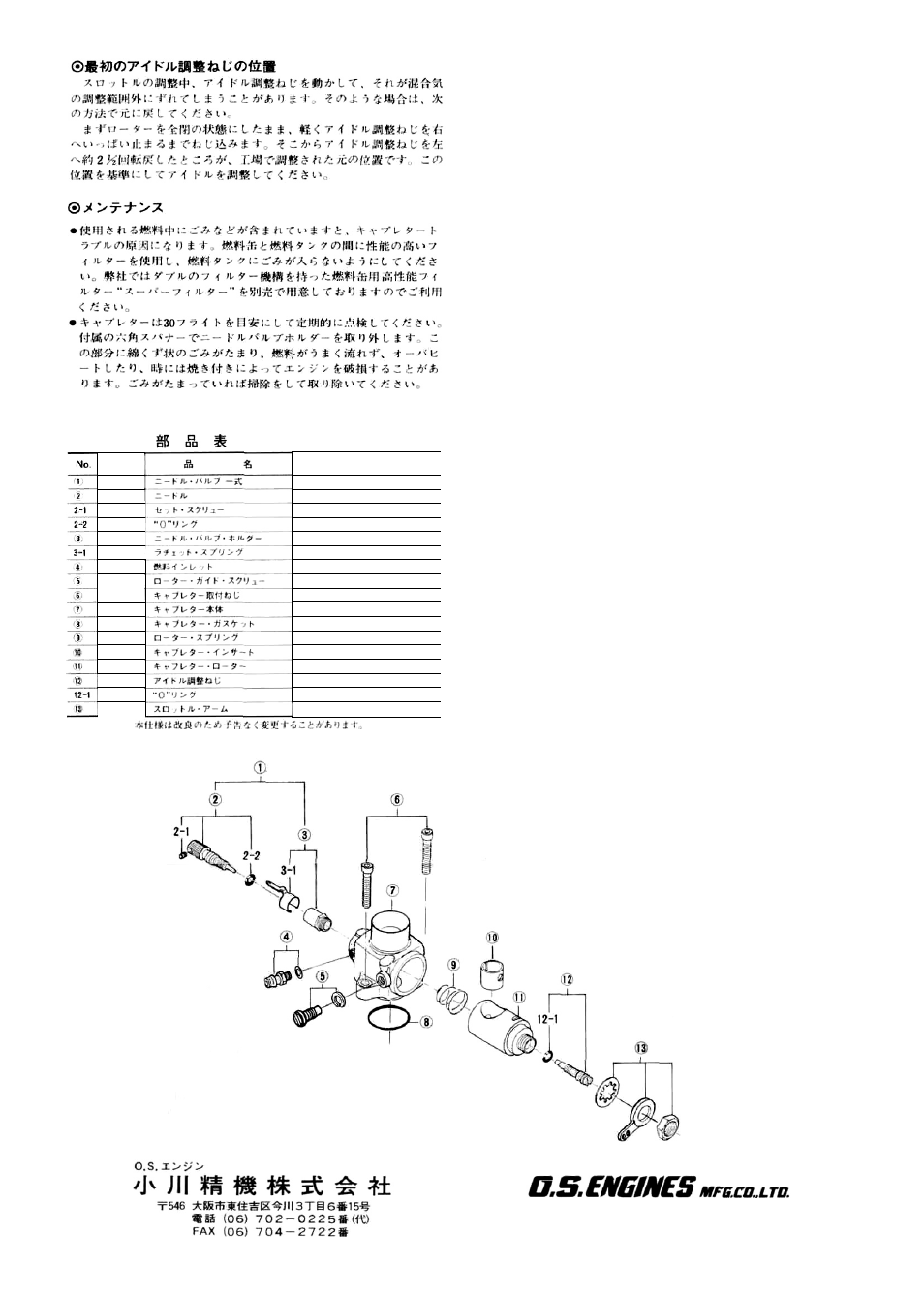

PARTS LIST

Description

Needle Valve Assembly

Needle

Set-screw

"0" Ring

Needle Valve Holder

Ratchet Spring

Fuel Inlet

Rotor Guide Screw

Carburettor Fixing Screw

Carburettor Body

Carburettor Rubber Gasket

Rotor Spring

Venturi Insert

Carburettor Rotor

Mixture Control Screw

"0" Ring

Throttle Lever Assembly

5) If, after carrying out mixture adjustments, the idling

speed is found to be too high, the throttle trim lever

on the transmitter may be retarded until the desired

idling speed is obtained.

Note: Once the correct carburettor settings have been

established, it should be unnecessary to alter them.

Such slight needle-valve readjustments as may be

required to compensate for variations in atmospheric

conditions will not normally affect the other two

controls. Slight readjustments may be necessary for

optimum performance if different types of fuel,

glowplugs or propellers are used.

REALIGNMENT OF MIXTURE CONTROL SCREW

The Mixture Control Screw is factory set at the approxi-

mate best position. If, however, it has been tampered with,

or moved accidentally, the factory setting can be re-

established as follows:

1) Set the throttle rotor in the fully closed position;

2) Carefully screw in the Mixture Control Screw until it

stops;

3) Unscrew the Mixture Control Screw 2 1/2 turns.

CARBURETTOR CLEANLINESS

Minute particles of foreign matter (present, to some extent,

in all fuels) will cause problems if not removed before they

reach the carburettor jet. Use high quality fuel filters and

make sure that the fuel tank and your refuelling container

are clean. The use of an O.S. Super-Filter Type L, with its

special double-filter system, is recommended. Installed

inside the refuelling can at its outlet, it will prevent the

passage of foreign matter into the fuel tank, and a good

inline filter, between tank and carburettor, will give added

protection.

Remember to clean the filters regularly. It is also advisable

to check the carburettor, itself, at least once every 30

flights. Remove the needle-valve holder, using the open-

ended wrench supplied, and extract any remaining dirt or

fibres that may have lodged in this part of the carburettor

body. If allowed to build up, such material can restrict

fuel flow and cause the engine to stop; or to run lean, with

the attendant risk of engine damage due to overheating.

8.&3-K

Code No.

28281900

28281970

26381501

24981837

27381940

26711305

22681953

28281600

24925202

29381100

29315000

28281500

28281210

28281200

29381300

27881820

28281400

The specifications are subject to alteration for improvement without notice.

6-15 3-chome Imagawa Higashisumiyoshi-ku

Osaka 546, Japan. TEL. (06) 702-0225

FAX. (06) 704-2722

© Copyright 1990 by OS. Engines Mfg. Co., Ltd. All rights reserved. Printed in Japan 19607