O.S. Engines 7H Carb - 23781011 User Manual

O.S. Engines Hardware

OPERATING INSTRUCTIONS FOR THE O.S. TYPE 7H CARBURETTOR

The O.S. Type 7H is an entirely new carburettor of advanced design that has been developed to meet the most exacting demands

of helicopter contest flying.

The Type 7H carburettor enables the user to adjust mixture strength separately for the low-power, medium-power and full-power

throttle ranges, in order to achieve optimum throttle response and complete reliability throughout the engine's operational spectrum.

Adjustment is simplified by the fact that each control works independently and does not upset response at higher or lower rpm.

This carburettor has many refinements including a ball-bearing mounted throttle rotor and is a precision made instrument of the

highest quality.

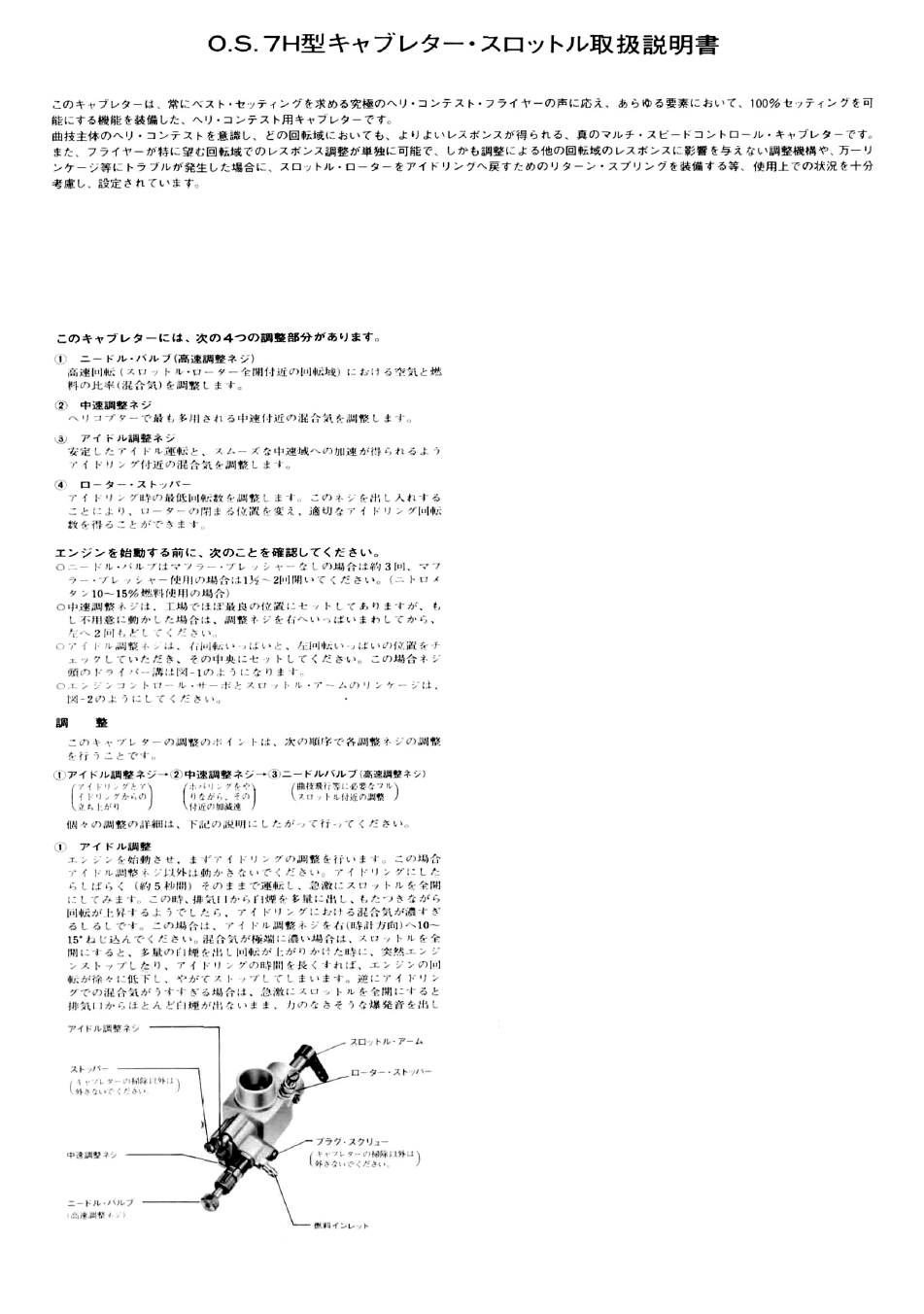

Throttle Stop Screw

Plug Screw

(Do not remove except when

cleaning the carburettor.)

Four adjustable controls are provided on the Type 7H carburettor

but it is quite simple to adjust. The controls are:

• The Needle-Valve: For adjusting the mixture strength when the

throttle is f u l l y open.

• The Mid-Range Mixture Control Screw: For adjusting the mixture

strength when the throttle is set for medium speeds — i.e. the range

which is most widely used in helicopter flight.

• The Idle Mixture Control Screw: For adjusting the mixture strength

when the engine is running at low speeds — i.e. the range between

idling speed and approximately "quarter-throttle"

• The Throttle Stop Screw: For establishing the minimum idling

speed.

PROVISIONAL SETTINGS

Before s t a r t i n g the engine, check that the controls are set as follows:

A Open the Needle-Valve three full turns (or 1 1/2 — 2 turns if muffler

pressurized fuel feed is used) from the fully closed position.

B The Mid-Range Mixture Control Screw is factory set at approxi-

mately the best position. If the adjustment has been moved, turn

the screw clockwise until it stops, then turn back counter-clockwise

two complete turns.

C The Idle Mixture Control Screw has an eccentric head which moves

approximately one-half turn from the full rich to full lean positions.

Make sure that this is set at the mid-way position. (Fig. 1)

ADJUSTING THE CARBURETTOR

The key to quick and positive adjustment is to adjust the controls

in the following order:

1. The Idle Mixture Control Screw (at idling speed).

2. The Mid-Range Mixture Control Screw (at hovering speed).

3. The Needle-valve (at full throttle).

1) Start the engine and allow it to idle for at least five seconds with

the throttle closed.

Now open the throttle. If the engine hesitates before picking up

speed, it is probable that the idling mixture is too rich. Check this

by closing the throttle again and letting the engine idle for a little

longer.

Re-open the throttle. If the engine now puffs out a good deal of

smoke and hesitates, or even stops, this will confirm that the

mixture is too rich. To correct this condition, gradually turn the

Idle Mixture Control Screw clockwise.

If, instead of being set too rich, the Idle Mixture Control Screw is

set too lean, the engine may stop when the throttle is closed, or it

may lose speed while idling and then cut out abruptly (without

smoke) when the throttle is re-opened. In this case, turn the Idle

Mixture Control Screw in the counter-clockwise direction.

Do not turn the Idle Mixture Control Screw more than 30 degrees

at a time and do not touch either of the other two mixture control

screws at this stage.

2) Having obtained a satisfactory idle mixture setting, open the

throttle to the "hovering speed' position. Once again, if the mixture

is too rich, this will be indicated by an excessively smoky exhaust.

This should be corrected by turning the Mid-Range Mixture Control

Screw clockwise about 45 degrees at a time.

Note: Turning the Mid-Range mixture Control Screw too far will

cause the mixture to become too lean and, although the engine may

continue to run, it may then become overheated if hovering flight is

prolonged. For safety, the Mid-Range Screw is normally set slightly

on the rich side at the factory.

3) Finally, adjust the Needle-Valve in the normal manner at full

throttle. In the case of fixed-wing models, it is customary to set the

needle-valve a little on the rich side of the setting at which maxi-

mum rpm are reached. The same applies to helicopters, but it is

advisable to set the needle-valve slightly richer than for a fixed wing

aircraft.

Remember that, with all three controls, clockwise rotation makes

the mixture weaker or 'lean' (ultimately resulting in a tendency to run

hot or cut out) while counter-clock-wise rotation makes the mixture

progressively richer (indicated by a smoky exhaust or uneven running).

However, if you become confused through turning an adjustment too

far, simply re-set the control in accordance with the recommended

'Provisional Settings' paragraph and begin adjustment again.

Throttle Lever

Idle Mixture

Control Screw

Stop Screw

(Do not remove except when

disassembling the carburettor.

Mid-Range Mixture

Control Screw

Needle Valve

(High speed mixture control)

Fuel Inlet