O.S. Engines 2CK Carb - 22781010 User Manual

Page 2

(b) If instead of being set too rich, the Mixture Control Screw

is set too lean, the engine will stop when the throttle is closed, or

will lose speed while idling and then cut-out abruptly (without

smoking) when the throttle is opened again. In this case, turn the

Mixture Control Screw counter-clockwise about 30 degrees, and

make sure that the mixture gets rich, then turn it clockwise

gradually.

Mixture Control Screw adjustment is not critical and by re-

membering the symptoms of rich and lean running quoted

above, it is a very simple matter to establish the best setting.

III. The Throttle Rotor Set-Screw is for establishing the mini-

mum idling speed. If the engine runs too fast with the throttle

closed, the Rotor Set-Screw should be turned counter-clockwise

to allow the throttle opening to be reduced.

SUBSEQUENT OPERATION AND CARE

Once the required settings have been established, it should be

unnecessary to alter them. Such slight needle-valve alterations as

may be necessary to cope with differences in atmospheric condi-

tions or fuels, do not affect the other two adjustments. The

engine should start readily with the throttle in the idle position.

It is important that the carburettor operates under clean condi-

tions. Make sure that fuel is properly filtered before use. We

advise fitting a filter to your fuel can and another filter in the

delivery tube between tank and engine, to reduce the risk of the

carburettor jet becoming partially clogged and upsetting running

adjustments. Remember to clean the filters periodically.

If, despite the use of filters, foreign matter should reach the

carburettor, causing it to malfunction, it should be carefully

dismantled and cleaned as follows:

( 1 ) Remove complete carburettor from engine. Clean off any

external dirt.

(2) Remove throttle rotor set screw.

(3) Withdraw rotor from carburettor body, taking care not to

lose the rotor spring placed behind rotor.

(4) Remove needle from needle-valve assembly, followed by

hexagonal retaining nut and ratchet spring. Now push

nozzle unit through body from outside.

(5) Remove fuel inlet nipple.

(6) Immerse parts in solvent (e.g. gasoline, alcohol or carbon-

tetrachloride) and clean thoroughly.

(7) Re-assemble in reverse order. Note that periphery of nozzle

flange is specially shaped to key into carburettor body.

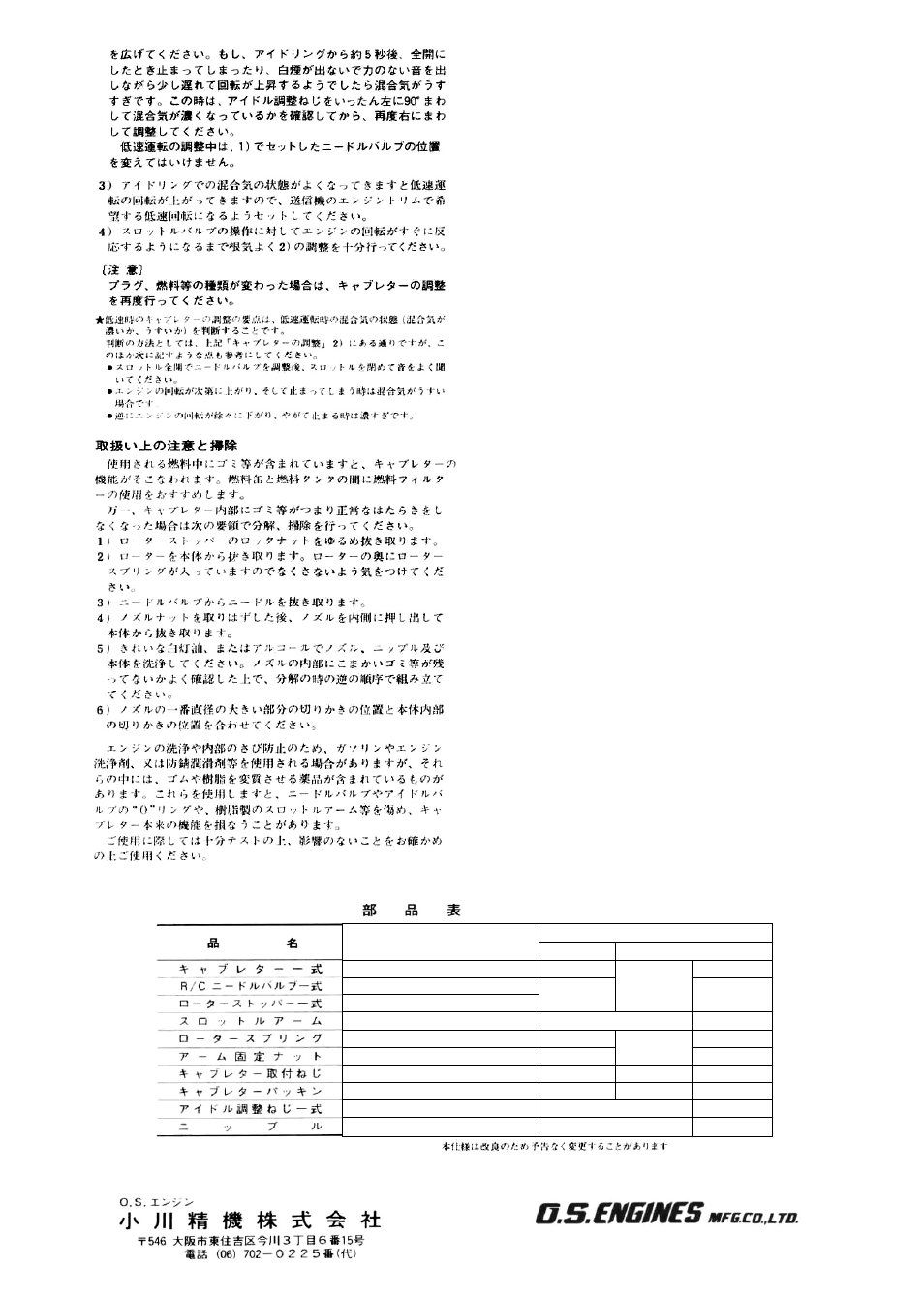

PARTS LIST

Description

Carburettor complete

R/C Needle valve assembly

Rotor stop set-screw assembly

Throttle lever

Rotor spring

Throttle lever fixing nut

Throttle fixing screws

Carburettor rubber gasket

Mixture control screw

Nipple

5, ^ 3 - K Code No.

2B

22681005

22681908

22681306

22681419 22481410

22481506

22481420

25081700

22615000

22481628 22481628

22681953 22681953

2CB-D 2CK

22481040

45181919

22681306

22481506

22481420

25081700

22615000

22781010

22681908

22681306

22781411

22481506

22781420

25081700

22615000

22781601

22681853

The specification are subject to alteration for improvement without notice.

6-15 3chome Imagawa Higashisumiyoshi ku

Osaka 546, Japan T E L Osaka (06) 702 0225

© Copyright 1988 by O.S. Engines Mfg. Co., Ltd. All rights reserved. Printed in Japan