Relocation of carburetor controls, Choke valve, Installation fuel tank – O.S. Engines FS-120S-E User Manual

Page 4

6

The needle-valve and throttle lever locations are

interchangeable by reversing the carburetor. This can be

done as follows:

Remove the carburetor carefully by unscrewing the two

screws which secure both carburetor and choke valve. (See

Photo 1.)

If the carburetor remains difficult to remove, slightly loosen the

two screws which secure the intake pipe to the cylinder head.

After reversing the carburetor, re-fit it to the intake pipe gently,

taking care not to damage the O-ring in the carburetor by

using foce.

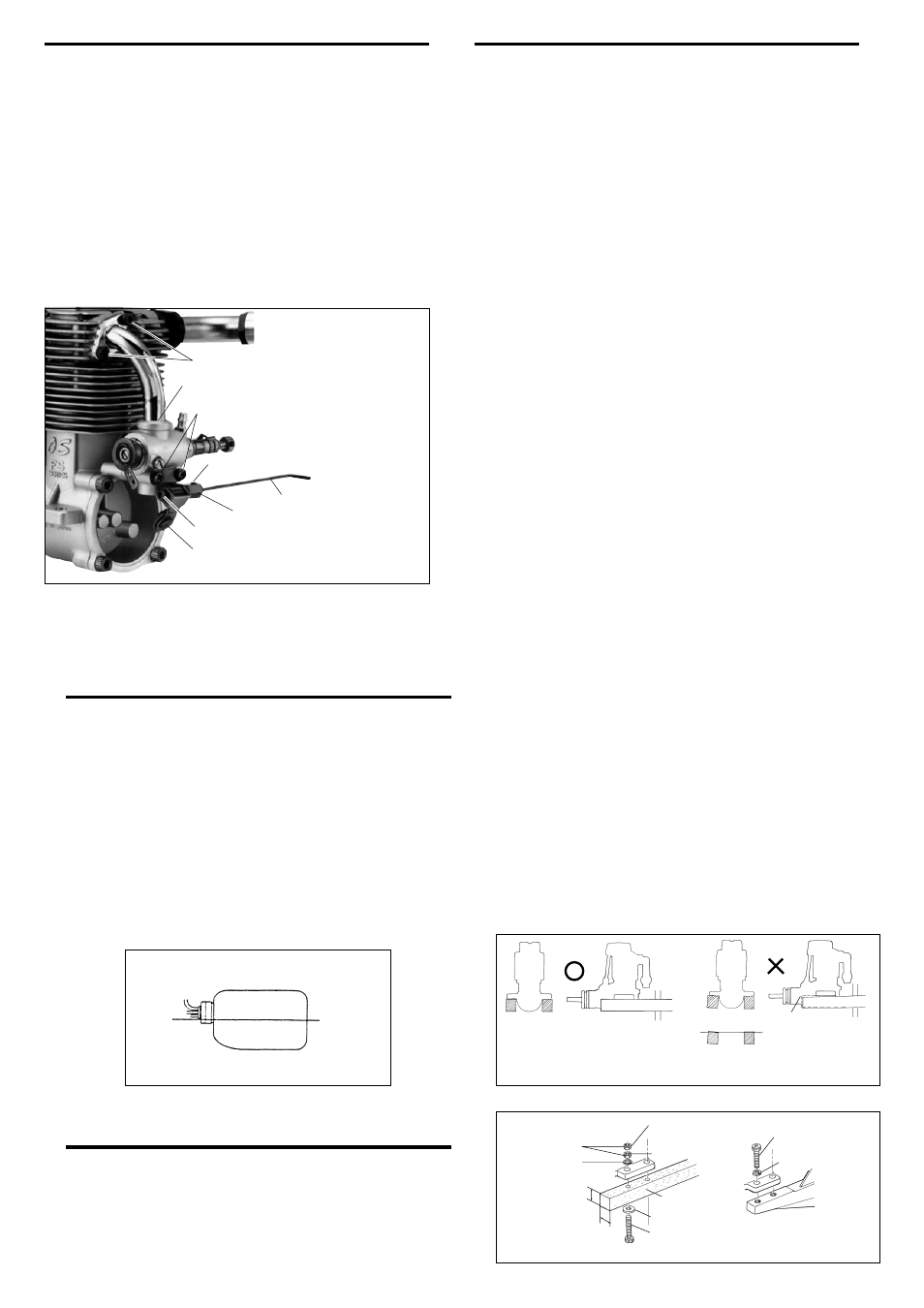

RELOCATION OF CARBURETOR CONTROLS

Intake Pipe Retaining Screw

"O" Ring

Carburetor Retaining Screw

Choke lever

Set screw

Hexagon nut

Cap screw

Choke rubber pad

Photo 1

CHOKE VALVE

The FS-120S-E is equipped with a spring-loaded choke valve.

The choke valve operating lever can be located right or left by

transposing the hexagon nut and cap screw.

After mounting the engine in the model, secure the L-shaped

choke rod by tightening the set-screw.

If the rod supplied is too long, reduce it to the required lebgth.

If the rod length is more than 40mm (1 1/2 in.) its outer end

should be supported to avoid vibration.

7

Because the FS-120S-E powerful, large-displacement, single-

cylinder four-stroke-cycle engines, it is essential to use very

substantial engine mounting. Conventional wooden mounting

beams should be of rigid hardwood and of at least 15mm or

5/8-in square section.

INSTALLATION

FUEL TANK

The suggested fuel tank size is 400cc or 14 oz. This will give

approximately 10 minutes running time when some part-

throttle operation is included. Locate the fuel tank so that the

centre line of the tank is 10 to 15mm below the centre line of

the needle-valve.

Make sure that the mounting beams are parallel and that their top

surfaces are in the same plane.

How to fasten the mounting screws.

Hardwood mounting beams

O.S. radial motor mount

(cast aluminum)

Tighten second nut firmly

down onto first nut.

Tighten this nut first.

Steel washer

5mm steel nuts

5mm steel screw

Spring washer or

lock washer

15mm min.

15mm min.

Hardwood such as

cherry or maple.

Spring washer

5mm steel Allen screw

Make sure that these mounting beams are accurately aligned

and firmly integrated with the airframe, reinforcing the

adjacent structure to absorb vibration. Use 5mm or larger

steel screws, preferably Allen type hexagon socket head cap

screws, with washers and locknuts, for bolting the engine to

the bearers. As an alternative to wooden beam mounting, a

special O.S. cast aluminium radial motor mount, complete with

5mm mounting screws, is available as an optional extra part

(Code No.71904200) , where front bulkhead (firewall) type

mounting is called for. Engine installation should, in any case,

be made in such a way that basic maintenance can be

conveniently carried out.

Front view

CORRECT

Side view

Top surfaces are in the same plane.

Re-align the surfaces

as necessary

INCORRECT

Top surfaces are not

in the same plane.

Opposite beam

Top surfaces are not

in the same plane.

Engine does not

rest firmly.

NOTE

If the model is left unattended with the fuel tank filled,

fuel may flow into the carburetor, causing it to "flood"

and making the engine difficult to start. Take appropriate

action to prevent this.

Centre line