Valve adjusting – O.S. Engines FS-52S User Manual

Page 18

In paragraphs 3 and 4 above, the 45

°

total

movements are, of course, approximate. It will be

necessary to fine-tune the mixture control screw

10-15

°

at a time to reach the best setting for

optimum throttle response.

Continue re-checking the idling mixture setting until

the engine responds smoothly and positively to

operation of the throttle at all times.

4.

5.

6.

On the other hand, if the engine hesitates before

picking up speed or even ceases firing completely,

the idling mixture is likely to be too lean. Turn the

mixture control valve 90

°

counter-clockwise to

substantially richen the mixture, then back again

45

°

clockwise.

In the course of making readjustments, it is just

possible that the mixture control screw may be

inadvertently screwed in or out too far and thereby

moved beyond its effective range.

Its basic position can be found by first rotating the

Mixture Control Valve unit its slotted head is flush

with the carburettor body. The valve is then screwed

in exactly 1 turn to re-establish the original setting.

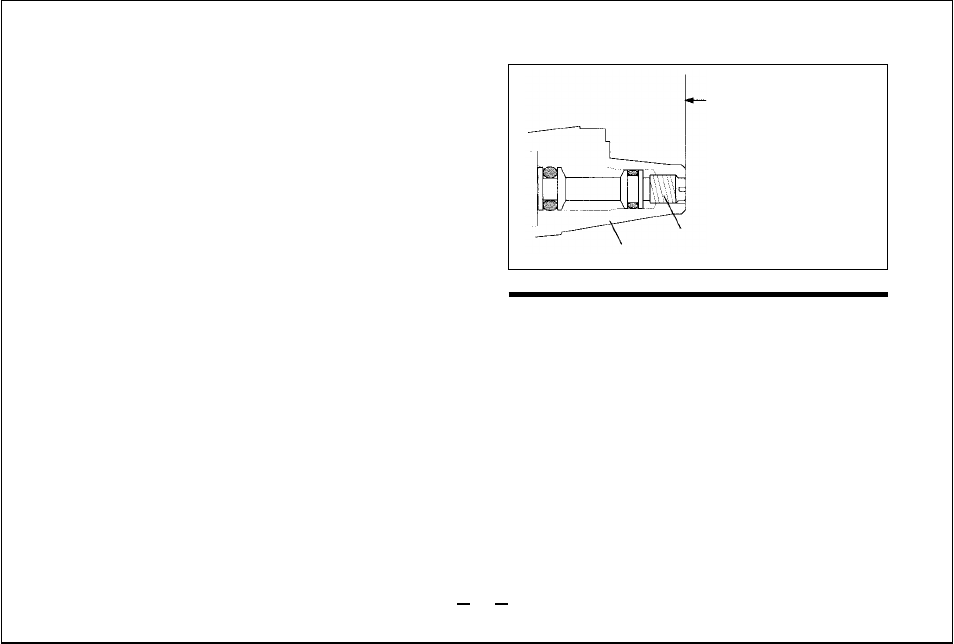

Realignment of Mixture Control Screw

First rotate the Mixture

Control Valve until its

slotted head is flush

with the carburettor body.

Mixture Control Valve

Carburettor Body

VALVE ADJUSTING

ALL O.S. four-stroke engines have their valve(tappet)

clearances correctly set before they leave the factory.

However, if, after many hours of running time have

been logged, a loss of power is detected, or if the

engine has to be disassembled or repaired as a result

of an accident, valve clearances should be checked

and readjusted, as necessary an O.S. Valve Adjusting

Tool Kit is available as an optional accessory.

17