Valve adjusting, How to set the camshaft timing – O.S. Engines FL-70 User Manual

Page 18

34

VALVE ADJUSTING

Valve clearances are correctly set before any

O.S. engine leaves the factory and, in normal

use, will seldom require adjustment. However,

if, after a considerable amount of running time,

a loss of power is detected, or if he engine has

been disassembled for repair, these

clearances should be checked and reset as

necessary.

For checking and adjusting the valve

clearances, a VALVE ADJUSTING TOOL KIT

is available as an optional accessory.

• Feeler gauge 0.04mm

The kit comes in a plastic case and includes:

(Code No.72200060)

• Feeler gauge 0.1mm

• Hex. key 1.5mm

• Wrench 5mm

35

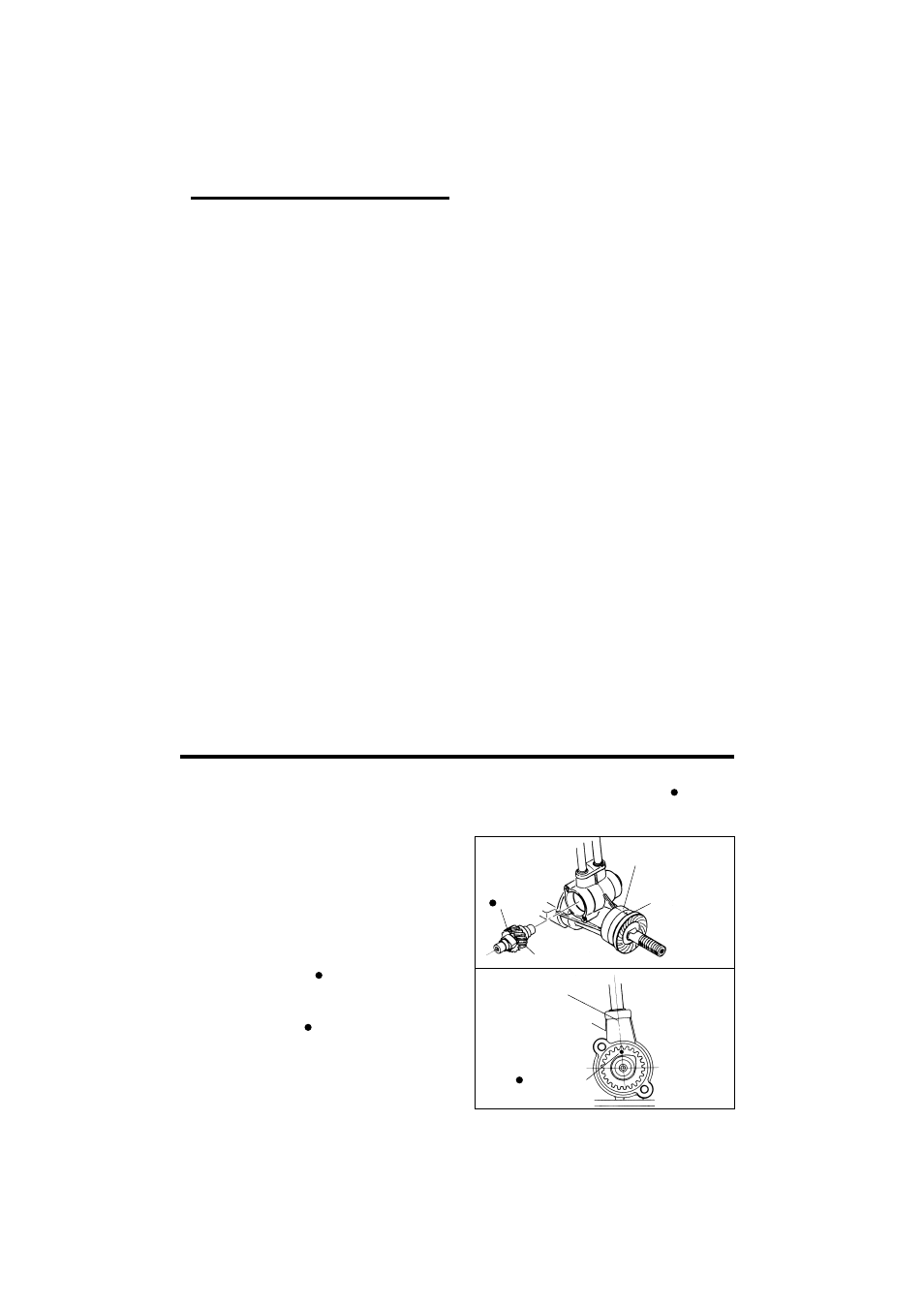

HOW TO SET THE CAMSHAFT TIMING

When replacing the camshaft, set the timing as

follows.

Secure propeller.

1.

NOTE:

If propeller is not secured, crankshaft may

move backward and correct timing cannot

be set.

Turn the crankshaft so that 'T' mark on the

drive hub may match crankcase center line.

(This is engine T.D.C. position)

2.

Push the camshaft into camshaft housing

until it stops. Locate ' ' mark on the side of

camshaft gear in line with the push rod.

3.

Rotate crankshaft right and left a little and

make sure that the ' ' mark on the gear is in

line with the push rod when the ' T ' mark on

the drive hub matches the crankcase center

line.

4.

Secure cam cover with screws.

5.

The relation of position between ' ' mark of

the gear and teeth may differ from the sketch,

by each model.

Fig.1

Fig.2

' ' mark

camshaft

crankcase

center line

'T' mark on

the drive hub

' ' mark of the

camshaft gear

in line with

the push rod