Installation – O.S. Engines 55AX User Manual

Page 8

14

8mm

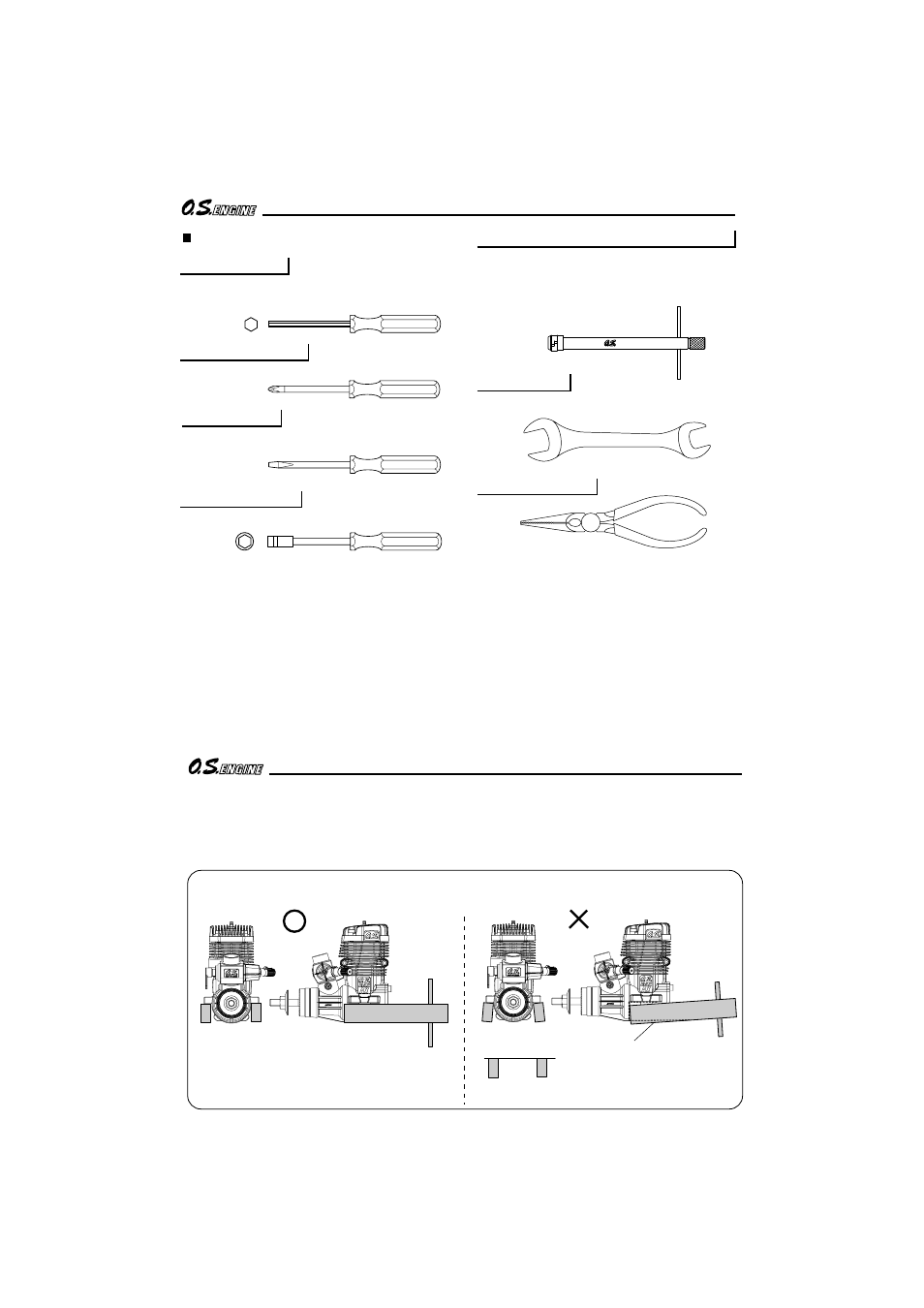

TOOLS

HEX Screwdriver

SCREWDRIVER

Necessary for engine installation.

1.5mm, 2.5mm

Necessary for carburetor adjustments.

Phillips Screwdriver

No.2, etc.

Socket Screwdriver

5mm, 5.5mm, 7mm

LONG SOCKET WRENCH WITH PLUG GRIP

Recommended for easy removal and

replacement of the angled and recessed

glowplug, the O.S.Long Socket Wrench

incorporates a special grip.

End Wrenches

10mm, etc.

Needle Nose Pliers

15

It is suggested to use as heavy and rigid as possible engine mounting for highest performance and

safe running. Conventional wooden mounting beams should be of rigid hardwood and of at least

15mm or 5/8-in square section. Use at least 3mm steel screws, such as Allen type, with locknuts, for

bolting the engine to the bearers..

INSTALLATION

CORRECT

Top surfaces are in the same plane.

INCORRECT

Front view

Side view

Re-align the surfaces

as necessary

Opposite beam

Top surfaces are not in the

same plane.

Engine does not rest firmly.

Top surfaces are not

in the same plane.

Make sure that the mounting beams are parallel and that their

top surfaces are in the same plane.