4 hydraulic plumbing: single acting – NORAC UC5-BC-HD07 User Manual

Page 31

28

10.4 Hydraulic Plumbing: Single Acting

From this point on in the installation the booms will be inoperative until the

hydraulics are fully installed.

1. After the NORAC valve is mounted, the hydraulic hoses and fittings can be plumbed. The

plumbing for the hydraulic circuit is shown schematically in Figure 3.

2. Install the 90 degree fittings on hoses H03 onto the “B” ports on the NORAC valve block.

3. Route the free ends of the hoses to each of the wing tilt cylinders.

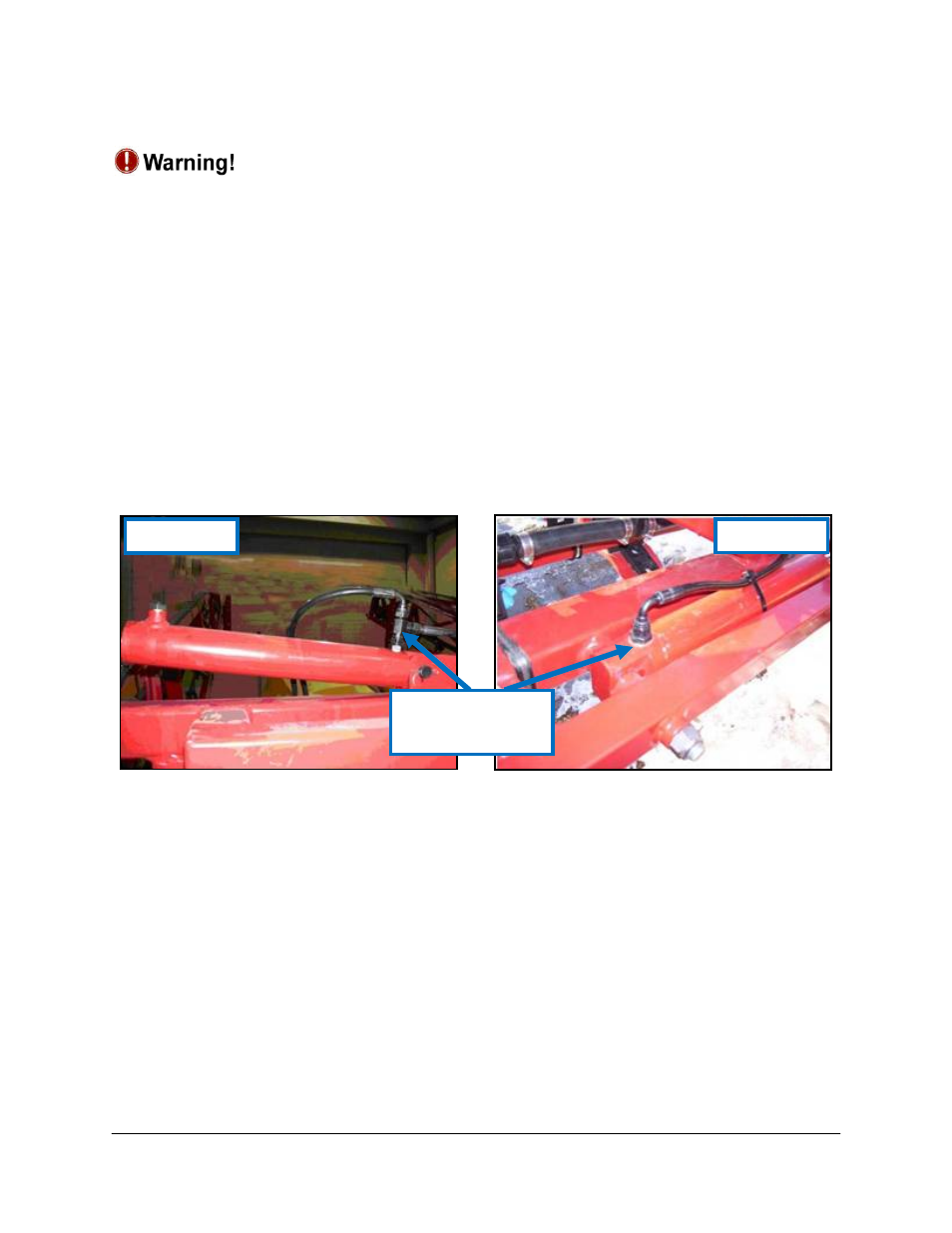

4. Remove the Hardi hoses from the “raise” line (the “B” line) of the cylinder and remove the

restricted straight BSPP fittings. (Figure 28)

5. Install the 4FBSPPX 6MJ fittings (F04) onto hoses H02. Install NORAC and Hardi hoses

onto the 4MBSPPT 4FBSPPRX tee (F05).

Figure 28: Restrictor to be Replaced on the Tilt Cylinders

6. At the Hardi main valve block, remove the hydraulic hoses that run from the “raise” line of

the tilt cylinders to the valve block (Figure 29). Remove the fittings from between the

hoses and valve block.

7. Install the restrictor that was removed from the wing tilt cylinder between the hoses and

the valve block. Install the fittings that were removed from the valve block between the

cylinders and tee fittings (F05).

8. Remove the pressure and tank hoses from the Hardi valve block and install the 4MBSPPT

4FBSPPRX tee (F05) between the valve block and hoses. Install the 4FBSPPX 6MJ fittings

(F04) onto hoses H01. Connect hoses H01 to each of the tee fittings and route to the

NORAC valve block. Install the corresponding hose to the pressure and tank port on the

NORAC valve block.

Eagle Boom

Force Boom

Replace this

Restrictor