Grounding warning, Assembly warning, Warning – Milwaukee Tool 5263-21 User Manual

Page 4: Specifications

4

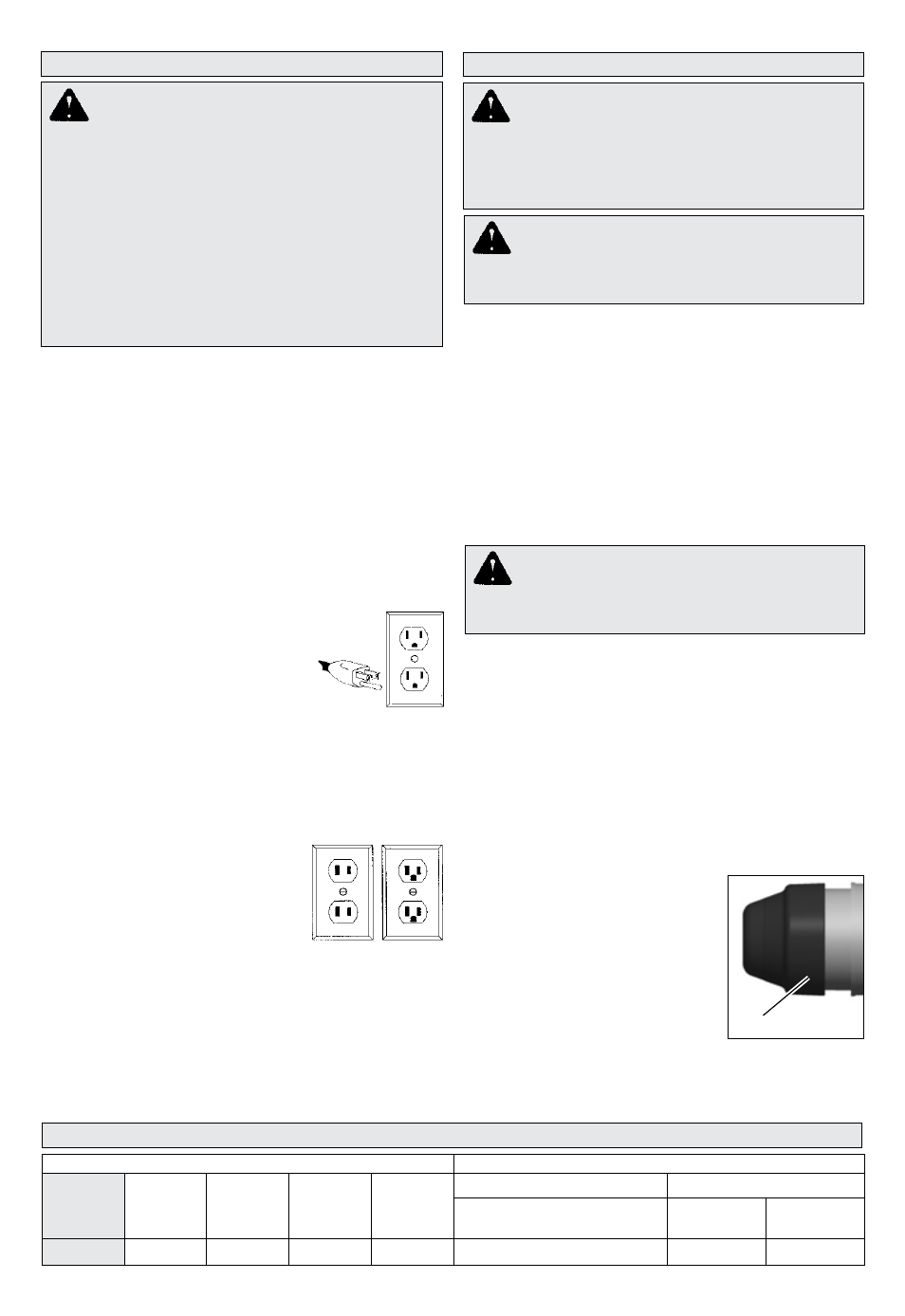

Fig. B Fig. C

Fig. A

grounding

Warning

Improperly connecting the

grounding wire can result in the risk of elec-

tric shock. Check with a qualified electrician

if you are in doubt as to whether the outlet is

properly grounded. Do not modify the plug

provided with the tool. Never remove the

grounding prong from the plug. Do not use

the tool if the cord or plug is damaged. If

damaged, have it repaired by a milWaukee

service facility before use. If the plug will not

fit the outlet, have a proper outlet installed by

a qualified electrician.

Grounded Tools: Tools with Three Prong Plugs

Tools marked “Grounding Required” have a three

wire cord and three prong grounding plug. The

plug must be connected to a properly grounded

outlet (See Figure A). If the tool should electrically

malfunction or break down, grounding provides a

low resistance path to carry electricity away from

the user, reducing the risk of electric shock.

The grounding prong in the plug is connected

through the green wire inside the cord to the

grounding system in the tool. The green wire in the

cord must be the only wire connected to the tool's

grounding system and must never be attached to

an electrically “live” terminal.

Your tool must be plugged into

an appropriate outlet, properly

installed and grounded in accord-

ance with all codes and ordinances.

The plug and outlet should look like

those in Figure A.

Double Insulated Tools:

Tools with Two Prong Plugs

Tools marked “Double Insulated” do not require

grounding. They have a special double insula-

tion system which satisfies OSHA requirements

and complies with the applicable standards of

Underwriters Laboratories, Inc.,

the Canadian Standard Asso-

ciation and the National Elec-

trical Code. Double Insulated

tools may be used in either of

the 120 volt outlets shown in

Figures B and C.

assembly

Warning

To reduce the risk of injury,

always unplug tool before changing or re-

moving accessories. Only use accessories

specifically recommended for this tool. Others

may be hazardous.

Warning

To reduce the risk of injury,

always use a side handle when using this tool.

Always brace or hold securely.

Adjusting the Side Handle Position

1. Loosen the side handle by unscrewing the side

handle grip until the side handle rotates freely.

2. Rotate the side handle to the desired position.

3. Tighten the side handle grip securely.

Setting the Depth Gauge

1. Press in the clamping lever.

2. Slide the depth gauge rod backward or forward

until it is set for the desired depth.

NOTE: The drilling depth is the distance between

the tip of the bit and the tip of the rod.

3. Release the clamping lever.

Warning

To reduce the risk of injury

do not grasp the bit while the chuck is rotat-

ing or while the bit is falling from the chuck.

Installing Drill Bits and Chisels

Only use accessories with SDS or SDS+ shanks.

Be sure that the shank of the bit is clean. Dirt parti-

cles may cause the bit to line up improperly. Do not

use bits larger than the maximum recommended

capacity of the drill because gear damage or mo-

tor overloading may result. For best performance,

be sure that the bit is properly sharpened and the

shank is lightly greased before use.

1. Insert the bit or chisel into the nose of the tool.

2. Rotate bit slowly until it aligns with the locking

mechanism.

3. Push bit into tool until it locks.

4. Check that the bit is locked

properly; it should be possible

to pull the bit back and forth

slightly (about 1/4").

5. To remove bits and chisels,

pull bit holder release collar

toward the rear of tool and

remove bit.

NOTE: Use caution when han-

dling hot bits and chisels.

Release collar

specificaTions

Tool

Capacities

Cat. No.

Volts

AC

A

No Load

RPM

No Load

BPM

Rotary Hammer

Drill Only

Carbide Tipped

Percussion Bit (concrete)

Twist Drill

Bit (Wood)

Twist Drill

Bit (Steel)

5263-20

120

5.5

0 - 3700 0 - 4400

5/8"

1"

1/2"