Milwaukee Tool 5363-21 User Manual

Page 4

6

7

WARNING

To reduce the risk of injury,

always use a side handle when using

this tool. Always brace or hold securely.

ASSEMBLY

WARNING

To reduce the risk of injury,

always unplug tool before attaching

or removing accessories or making adjust-

ments. Use only specifi cally recommended

accessories. Others may be hazardous.

OPERATION

WARNING

To reduce the risk of injury,

always unplug tool before attaching

or removing accessories or making adjust-

ments. Use only specifi cally recommended

accessories. Others may be hazardous.

WARNING

To reduce the risk of injury,

keep hands and cord away from the bit

and all moving parts.

WARNING

To reduce the risk of injury,

wear safety goggles or glasses with side

shields.

Drilling

Depth

Bit holder

release

collar

Adapter

Core

Bit

Center

Pin

Guide

Plate

Clean

and

lubricate

threads

Adjusting the Side Handle Position

1. Loosen the side handle by unscrewing the side

handle grip until the side handle rotates freely.

2. Rotate the side handle to the desired position.

3. Tighten the side handle grip securely.

Setting the Depth Gauge

1. Press in the clamping lever.

2. Slide the depth gauge rod backward or forward

until it is set for the desired depth.

NOTE: The drilling

depth is the distance

between the tip of the

bit and the tip of the

depth gauge rod.

3. Release the clamping lever.

Installing Drill Bits and Chisels

NOTE: Only use accessories with SDS or SDS

Plus shanks.

Be sure that the shank of the bit is clean. Dirt par-

ticles may cause the bit to line up improperly. Do not

use bits larger than the maximum recommended

capacity of the drill because gear damage or mo-

tor overloading may result. For best performance,

be sure that the bit is properly sharpened and the

shank is lightly greased before use.

1. Insert the bit or chisel into the nose of the tool.

2. Rotate bit slowly until it aligns with the locking

mechanism.

3. Push bit into tool until it locks.

4. Check that the bit is locked properly; it should

be possible to pull the bit back and forth slightly

(about 1/4”).

5. To remove bits and

chisels, pull bit holder

release collar toward

the rear of tool and

remove bit.

NOTE: Use caution

when handling hot

bits and chisels.

Selecting Action

MILWAUKEE Rotary Hammers have three settings:

drill only, rotary hammer, and hammer only.

1. For drilling, turn the

selector lever so the

arrow on the lever

points to the twist

drill symbol.

2. For rotary hammer-

ing, turn the selector

lever so the arrow

points to the ham-

mer and twist drill

symbol.

3. For hammering only, turn the selector lever so

the arrow points to the hammer symbol.

4. To freely rotate the bit to the desired angle for

chiseling only, turn the selector lever so the arrow

points to the

O

symbol. Then, follow step 3.

Using the Control Switch

The control switch may be set to three positions:

forward, reverse and lock. Due to a lockout mecha-

nism, the control switch can only be adjusted when

the trigger is not pulled. Always allow the motor to

come to a complete stop before using the control

switch.

For forward (clockwise)

rotation, push the control

switch to the left side of the

tool. Check the direction of

rotation before use.

For reverse (counterclock-

wise) rotation, push the control switch to the right

side of the tool. Check direction of rotation before

use.

Starting, Stopping and Controlling Speed

1. To start the tool, grasp the handle fi rmly and pull

the trigger.

2. To vary the speed, increase or decrease the

pressure on the trigger. The further the trigger

is pulled, the greater the speed.

3. To stop the tool, release the trigger. Make sure

the tool comes to a complete stop before laying

the tool down.

Operating

Position the tool, grasp the handles fi rmly and pull

the trigger. Always hold the tool securely using both

handles to maintain control. This tool has been

designed to achieve top performance with only

moderate pressure. Let the tool do the work.

If the speed begins to drop off when drilling large

or deep holes, pull the bit partially out of the hole

while the tool is running to help clear dust. Do not

use water to settle the dust since it will clog the bit

fl utes and tend to make the bit bind in the hole. If

the bit should bind, a built-in, non-adjustable slip

clutch prevents the bit from turning. If this occurs,

stop the tool, free the bit and begin again.

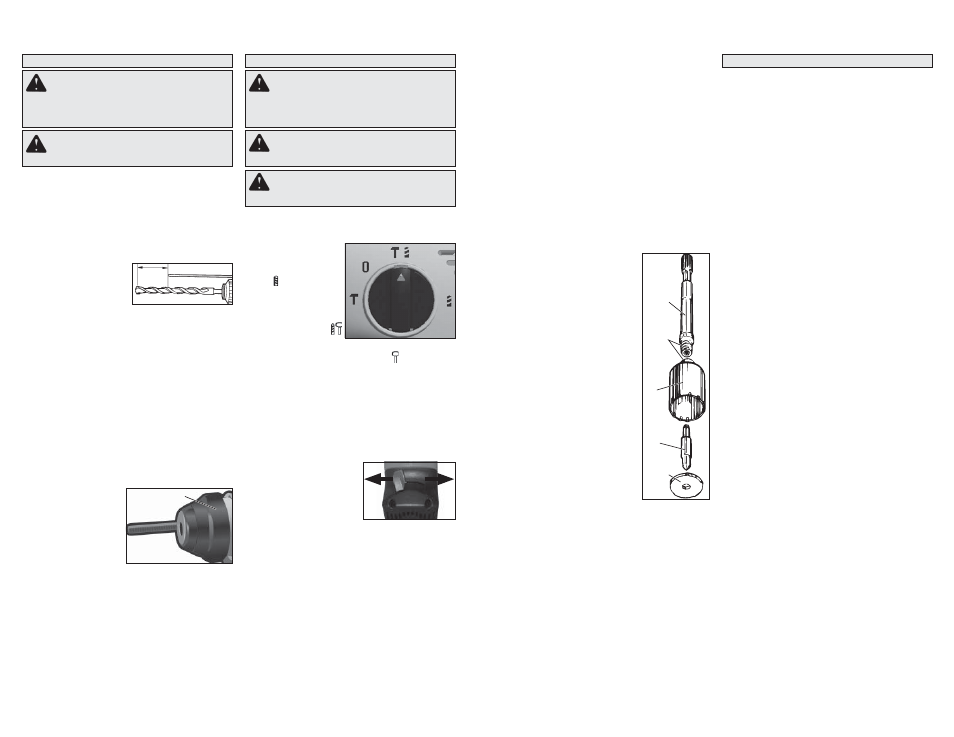

Using Core Bits

Core bits are useful for drilling large holes for

conduit and pipe. MILWAUKEE Heavy-Duty Thin

Wall Core Bits have heat treated steel bodies with

durable carbide tips. They are specially designed

for fast, accurate drilling with combined hammering

and rotary action.

1. Clean and lubricate the threads

on the adapter and core bit as

indicated to make later removal

easier. Screw the threaded end

of the adapter into the rear of

the core bit.

2. Push the guide plate onto the

pointed end of the center pin.

Insert the center pin with guide

plate a ssembly into to the core

bit. Be sure the small end of the

center pin is securely placed

into the hole in the center of the

adapter.

3. Insert the adapter into the bit

holder of the tool as described

in “Inserting Drill Bit or Chisel”.

Set the rotary hammer/drill

lever to rotary hammer.

4. Press the center pin firmly

against your center mark, hold

the tool fi rmly and pull the trig-

ger.

5. After drilling to about the depth

of the core bit teeth, remove

the center pin and guide plate from the core bit.

Resume drilling.

6. After you have fi nished drilling the hole, hold the

tool upwards, pointing it away from your body,

and run it briefl y in forward to loosen the core

bit from the adapter.

MILWAUKEE Heavy-Duty Thin Wall Core Bits

drill holes up to 3" deep. To make deeper holes,

remove the bit, break and remove the core. Re-

sume drilling.

Forward

Reverse

APPLICATIONS

Drilling in Wood, Composition Materials and

Plastic

When drilling in wood, composition materials and

plastic, select the drill operating mode. Start the

drill slowly, gradually increasing speed as you drill.

Select low speeds for plastics with a low melting

point.

Drilling in Metal

When drilling in metal, select the drill operating

mode. Use high speed steel twist drills or hole

saws. Use a center punch to start the hole. Lubri-

cate drill bits with cutting oil when drilling in iron

or steel. Use a coolant when drilling in nonferrous

metals such as copper, brass or aluminum. Back

the material to prevent binding and distortion on

breakthrough.

Drilling in Masonry

When drilling in masonry, select the rotary hammer

operating mode. Use high speed carbide-tipped

bits. Drilling soft masonry materials such as cinder

block requires little pressure. Hard materials like

concrete require more pressure. A smooth, even

fl ow of dust indicates the proper drilling rate. Do

not let the bit spin in the hole without cutting. Do

not use water to settle dust or to cool bit. Do not

attempt to drill through steel reinforcing rods. Both

actions will damage the carbide.