Milwaukee Tool 8988-20 User Manual

Page 3

4

5

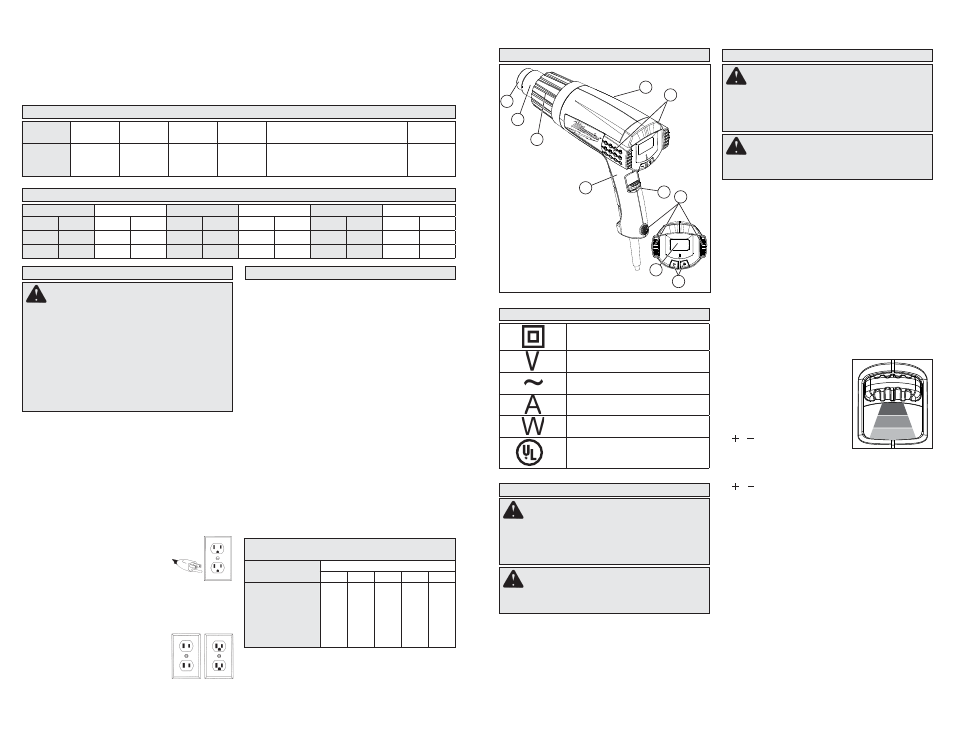

1. Accessory

attachment

area

2. Nozzle

3. Front cover

4. Nameplate (on back)

5. Intake vents

6. Handle

7. ON/OFF/Airfl ow switch

8. Support stand bumpers

9. LCD

10. Temperature controls

Grounded Tools: Tools with Three Prong Plugs

Tools marked “Grounding Required” have a three wire

cord and three prong grounding plug. The plug must be

connected to a properly grounded outlet (See Figure

A). If the tool should electrically malfunction or break

down, grounding provides a low resistance path to

carry electricity away from the user, reducing the risk

of electric shock.

The grounding prong in the plug is connected through

the green wire inside the cord to the grounding system

in the tool. The green wire in the cord must be the only

wire connected to the tool's grounding system and

must never be attached to an electrically “live” terminal.

Your tool must be plugged into an appropriate

outlet, properly installed and grounded in accor-

dance with all codes and ordinances.

The plug and outlet should look like

those in Figure A.

Double Insulated Tools: Tools with Two Prong Plugs

Tools marked “Double Insulated” do not require

grounding. They have a special double insulation

system which satisfi es OSHA requirements and com-

plies with the applicable standards of

Underwriters Laboratories, Inc., the

Canadian Standard Association and

the National Electrical Code. Double

Insulated tools may be used in ei-

ther of the 120 volt outlets shown in

Figures B and C.

Grounded tools require a three wire extension cord.

Double insulated tools can use either a two or three wire

extension cord. As the distance from the supply outlet

increases, you must use a heavier gauge extension

cord. Using extension cords with inadequately sized

wire causes a serious drop in voltage, resulting in loss

of power and possible tool damage. Refer to the table

shown to determine the required minimum wire size.

The smaller the gauge number of the wire, the greater

the capacity of the cord. For example, a 14 gauge cord

can carry a higher current than a 16 gauge cord. When

using more than one extension cord to make up the total

length, be sure each cord contains at least the minimum

wire size required. If you are using one extension cord for

more than one tool, add the nameplate amperes and use

the sum to determine the required minimum wire size.

Guidelines for Using Extension Cords

• If you are using an extension cord outdoors, be sure

it is marked with the suffi x “W-A” (“W” in Canada) to

indicate that it is acceptable for outdoor use.

• Be sure your extension cord is properly wired and in

good electrical condition. Always replace a damaged

extension cord or have it repaired by a qualifi ed person

before using it.

• Protect your extension cords from sharp objects,

excessive heat and damp or wet areas.

each work session, place paint scrapings in a double

plastic bag, close it with tape or twist ties and dispose.

• Remove protective clothing and work shoes

in the work area to avoid transferring dust to

Fig. B

Fig. C

GROUNDING

SPECIFICATIONS

* Cubic feet per minute

Cat. No.

Volts AC

Max.

Amps

Max.

Watts

Switch

Setting

Temperature

Airfl ow

CFM*

8988-20

120

12.5

1500

I

II

III

120°F (49°C)

120°F - 1150°F (49°C - 621°C)

120°F - 1150°F (49°C - 621°C)

3.6

10.6

17.6

READ AND SAVE ALL

INSTRUCTIONS FOR FUTURE USE.

* Based on limiting the line voltage drop to fi ve volts

at 150% of the rated amperes.

EXTENSION CORDS

FUNCTIONAL DESCRIPTION

SYMBOLOGY

Double Insulated

Volts

Alternating Current

Amps

Watts

C

US

Underwriters Laboratories, Inc.

United States and Canada

other parts of the building. Wash work clothes

separately. Wipe shoes off with a wet rag that is then

washed with the work clothes. Wash hair and body

thoroughly with soap and water.

SAVE THESE INSTRUCTIONS

ASSEMBLY

Installing/Removing Nozzles

1. To install, slide the nozzle onto the heat gun

nose.

2. Adjust heat, airfl ow, distance and length of ap-

plication as necessary.

3. To remove, allow tool to cool to room tempera-

ture, then pull nozzle away from tool.

OPERATION

Selecting Temperature

The proper amount of heat for each application

depends on the temperature selected, distance

between the nozzle and workpiece, and the length

of time heat is applied. Experiment with scrap ma-

terials and start with the lowest temperature. Be

cautious when working until the proper combination

of heat, distance and time of application has been

obtained. Use a back and forth motion when ap-

plying heat unless concentrated heat is desirable.

When done, allow the nozzle to cool by placing the

tool upright on a fl at surface using the support stand

areas. Place the cord so the heat gun won’t tip.

The electronic temperature control system

regulates the temperature within the tool's heat-

ing element. Unlike non-electronic heat guns,

MILWAUKEE's electronic heat gun will maintain

the temperature.

1. For Low Airfl ow/Low Tem-

perature, push the switch to

the (I) position.

2. For Medium Airflow/Vari-

able Temperature, push

the switch to the (II) posi-

tion. Use the temperature

/ buttons to increase or

decrease the temperature

(100°F - 1100°F) by 10°F increments.

3. For High Airfl ow/Variable Temperature, push the

switch to the (III) position. Use the temperature

/ buttons to increase or decrease the tem-

perature (100°F - 1100°F) by 10°F increments.

When the tool is switched OFF, the last selected

temperature is retained.

Hands-Free Use

The heat guns can be positioned upright on a stable

surface, leaving both hands free for the application.

Always place the tool upright on a fl at surface using

the support stand areas. Place the cord so the heat

gun won’t tip. The rear vent openings are designed

to allow air fl ow even when the tool is resting on

the end cap. Do not cover the vents with foreign

materials such as clothing or rags.

Types of Nozzles

• Hook Nozzle - Surrounding heat for thin pipe weld-

ing, soft soldering copper pipes, tube shaping and

shrinking of shrink tubes.

• Air Reduction Nozzle - Intensifi ed, spot directed

heat for corners, plexiglas bending and soldering.

WARNING

Improperly connecting the

grounding wire can result in the risk of electric

shock. Check with a qualifi ed electrician if you

are in doubt as to whether the outlet is properly

grounded. Do not modify the plug provided with

the tool. Never remove the grounding prong

from the plug. Do not use the tool if the cord or

plug is damaged. If damaged, have it repaired

by a MILWAUKEE service facility before use.

If the plug will not fi t the outlet, have a proper

outlet installed by a qualifi ed electrician.

WARNING

To reduce the risk of injury,

do not remove or attach accessory tips until

tool has cooled to room temperature.

WARNING

To reduce the risk of injury,

always unplug tool before attaching or remov-

ing accessories or making adjustments. Use

only specifi cally recommended accessories.

Others may be hazardous.

WARNING

To reduce the risk of injury,

wear safety goggles or glasses with side

shields.

WARNING

To reduce the risk of injury,

always unplug tool before attaching or remov-

ing accessories or making adjustments. Use

only specifi cally recommended accessories.

Others may be hazardous.

Fig. A

8

2

1

3

6

7

5

4

10

9

Recommended Minimum Wire Gauge

For Extension Cords*

Nameplate Amps

Extension Cord Length

25'

50'

75'

100'

150'

0 - 2.0

2.1 - 3.4

3.5 - 5.0

5.1 - 7.0

7.1 - 12.0

12.1 - 16.0

16.1 - 20.0

18

18

18

18

16

14

12

18

18

18

16

14

12

10

18

18

16

14

12

10

--

18

16

14

12

10

--

--

16

14

12

12

--

--

--

I

II

III

TEMPERATURE CONVERSIONS

°C = °F

°C = °F

°C = °F

°C = °F

°C = °F

°C = °F

38

100

149

300

260

500

371

700

482

900

593

1100

93

200

200

392

300

572

400

752

500

932

600

1112

100

212

204

400

316

600

427

800

538

1000

649

1200