Milwaukee Tool 2680-22 User Manual

Page 4

6

7

Cat. No.

Volts

DC

No Load

RPM

Spindle

Thread Size

Wheel

Size

2680-20

18

9000

5/8"-11

4-1/2"

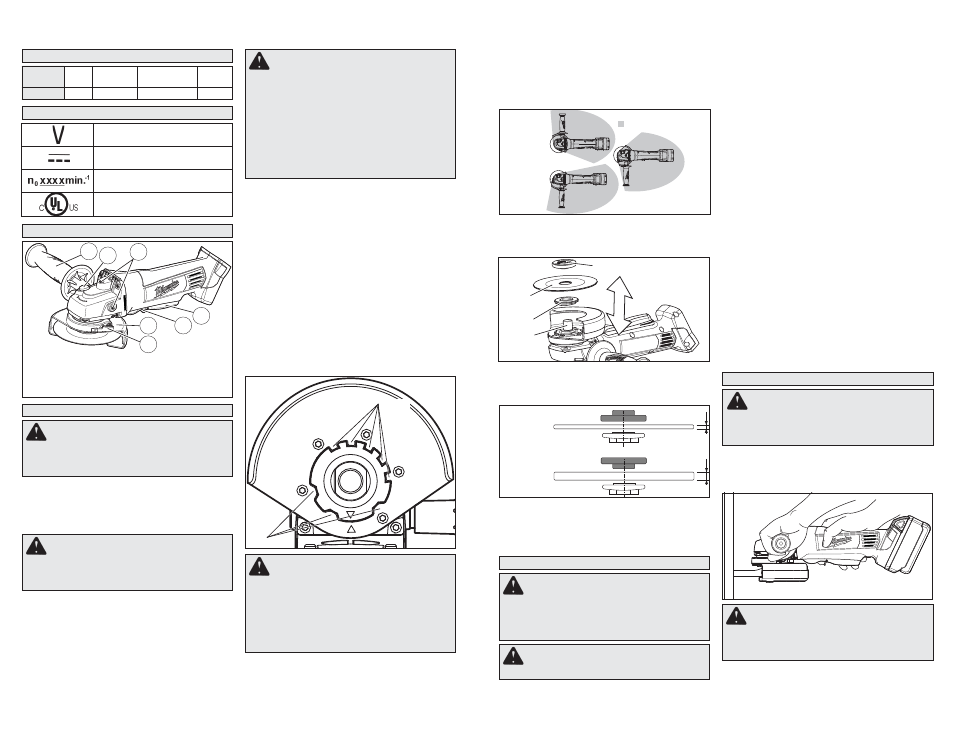

FUNCTIONAL DESCRIPTION

SYMBOLOGY

SPECIFICATIONS

ASSEMBLY

WARNING

Recharge only with the

charger specifi ed for the battery. For specifi c

charging instructions, read the operator’s

manual supplied with your charger and battery.

Inserting/Removing the Battery

To remove the battery, push in the release buttons

and pull the battery pack away from the tool.

To insert the battery, slide the pack into the body of

the tool. Make sure it latches securely into place.

1. Side handle

2. Spindle lock

3. Side handle sockets

4. Paddle switch

1

4

5

6

7

3

2

5. Switch lock-off

6. Guard

7. Guard lock lever

Installing Side Handle

The side handle may be installed on either side

or the top of gear case. Position side handle in

the location which offers best control and guard

protection. To install, thread side handle into side

handle socket and tighten securely.

Installing, Removing and Adjusting the Guard

This tool is shipped with a guard. A guard must be

used when using the tool as a grinder. The guard

may be removed when using tool as a sander.

1. To remove the guard, remove the battery pack

and remove any accessories from spindle.

2. Press in the lock lever and rotate the guard to

line up the tabs on the grinder with the slots in

the guard.

3. Press in the lock lever and lift the guard straight

up and away from the tool.

4. To install the guard, remove the battery pack

and remove any accessories from the spindle.

5. Line up the tabs on the grinder with the slots in

the guard.

6. Press in the lock lever and press the guard onto

the tool.

7. To adjust the guard, press in the lock lever and

rotate the guard to one of fi ve detent slots.

WARNING

To reduce the risk of injury

when grinding:

• ALWAYS use the proper guard.

• ALWAYS properly install the guard.

• ALWAYS hold the tool fi rmly with both

hands using the handles provided before

and during grinding.

• NEVER use a wheel that has been dropped.

• NEVER bang grinding disc onto work.

• NEVER grind without proper safety

equipment.

Tab

slots

Fig. 1

Detent

slots

WARNING

Always remove battery

pack before changing or removing accesso-

ries. Only use accessories specifi cally recom-

mended for this tool. Others may be hazardous.

Installing/Removing Accessories

Make sure the wheel does not extend beyond the

bottom of the guard. Threaded hub grinding wheels

may require a deeper guard (see "Accessories").

1. Remove the battery pack.

2. Properly position the guard (Fig. 2).

WARNING

Only use accessories with

Maximum Safe Operating Speed rated at least

equal to the maximum speed marked on the

power tool. This speed is based on the strength

of the wheel, allowing for a reasonable mea-

sure of safety. It is not meant to imply a best or

most effi cient operating speed. Do not exceed

the Maximum Safe Operating Speed.

Controlled Start

The controlled start feature reduces the torque

reaction "jerk" when its trigger is pulled.

Paddle Switch Operation

To start the tool, grasp the handle and side handle

fi rmly. Pull the lock-off button back and squeeze

the paddle switch.

To stop the tool, release the paddle switch. Make

sure the tool comes to a complete stop before lay-

ing the tool down.

General Operation

1. If you have just installed an accessory or are

beginning a period of work, test it by letting it

spin for one minute before applying it to the

workpiece. Out-of-balance or damaged acces-

sories can mar workpiece, damage the tool, and

cause stress that may cause accessory failure.

2. Use a clamp, vise or other practical means to

hold your work, freeing both hands to control

the tool.

3. Hold tool securely with both hands.

4. Start the tool.

5. Allow accessory to come to full speed before

beginning work.

6. Control pressure and surface contact between

accessory and workpiece. Too much pressure

slows speed.

If the tool stalls, release the trigger to reset.

Lighten pressure to avoid stalling.

7. When fi nished, turn off the tool and make sure

it comes to a complete stop before laying it

down.

OPERATION

WARNING

Always remove battery

pack before changing or removing acces-

sories. Only use accessories specifically

recommended for this tool. Others may be

hazardous.

WARNING

To reduce the risk of injury,

wear safety goggles or glasses with side shields.

5. Place the selected wheel on the spindle and align

it with the fl ange.

6. Position the fl ange nut over the spindle according

to wheel thickness (Fig. 4).

7. Press in the spindle lock button while turning the

fl ange nut clockwise. Tighten securely using a

spanner wrench.

8. To remove wheel, remove the battery pack and

reverse the procedure.

Flange nut

position for

1/8" thick or less wheels

Fig. 4

1/8"

1/4"

Flange nut

position for

1/4" thick or more wheels

Fig. 2

Operator's Zones

Spindle

Flange

Wheel

Flange nut

Fig. 3

3. Wipe the flange, flange nut and spindle to

remove dust and debris. Inspect the parts for

damage. Replace if needed.

4. Place the fl ange on spindle, as shown.

Fig. 6

WARNING

A Type "1" guard must be

installed when using a cut-off wheel to provide

maximum protection for the operator if the

wheel should break.

WARNING

Using the face of a Cut-Off

Wheel (as in grinding) will cause the Wheel

to crack and break, resulting in serious per-

sonal injury.

USING CUT-OFF WHEELS

Type "1" Cut-Off Wheels are suited for small cut-off

and shallow notching operations only.

When using a cut-off wheel, hold the tool as shown,

using only the edge of the wheel.

Volts

Direct Current

No Load Revolutions per

Minute (RPM)

Underwriters Laboratories, Inc.

United States and Canada