Gas & oil fill-up, Testing drive control & shift lever, Adjusting drive and auger controls – Cub Cadet 928 SWE User Manual

Page 10

WARNING!

Do not over-tighten the cable. Over-

tightening may prevent the auger from disengaging

and compromise the safety of the snow thrower.

If adjusting the auger cable, thread the lock nut down to

4.

lengthen the cable as necessary to stop the auger from

turning when the control is released.

Securely hook the cable’s spring into the rear most hole of the

5.

respective actuator bracket.

Repeat the wheel drive and auger control tests to verify proper

6.

adjustment. Repeat previous steps if necessary to attain

proper adjustment of each cable

Gas & Oil Fill-Up

WARNING!

Use extreme care when handling

gasoline. Gasoline is extremely flammable and the

vapors are explosive. Never fuel the machine indoors

or while the engine is hot or running. Extinguish

cigarettes, cigars, pipes and other sources of ignition.

Service the engine with gasoline and oil as instructed in the

separate Engine Owner’s Manual included with this unit. Read

those instructions carefully.

With the auger control in the disengaged “up” position, walk to

4.

the front of the machine.

Confirm that the auger has completely stopped rotating and

5.

shows NO signs of motion. If the auger shows ANY signs

of rotating, immediately return to the operator’s position

and shut off the engine. Wait for ALL moving parts to stop

before re-adjusting the auger control.

Testing Drive Control & Shift Lever

With the engine turned off, move the shift lever into sixth

1.

(6) position. Refer to Figure 3-8.

With the wheel drive control released, push the snow

2.

thrower forward, then pull it back. The machine should

move freely.

Engage the drive control and attempt to move the machine

3.

both forward and back, resistance should be felt.

Move the shift lever into the fast reverse (R2) position and

4.

repeat the previous two steps.

If you experienced resistance rolling the unit, either

5.

when repositioning the shift lever from 6 to R2 or when

attempting to move the machine with the drive control

released, adjust the drive control immediately. See

Adjusting Drive and Auger Controls.

Adjusting Drive and Auger Controls

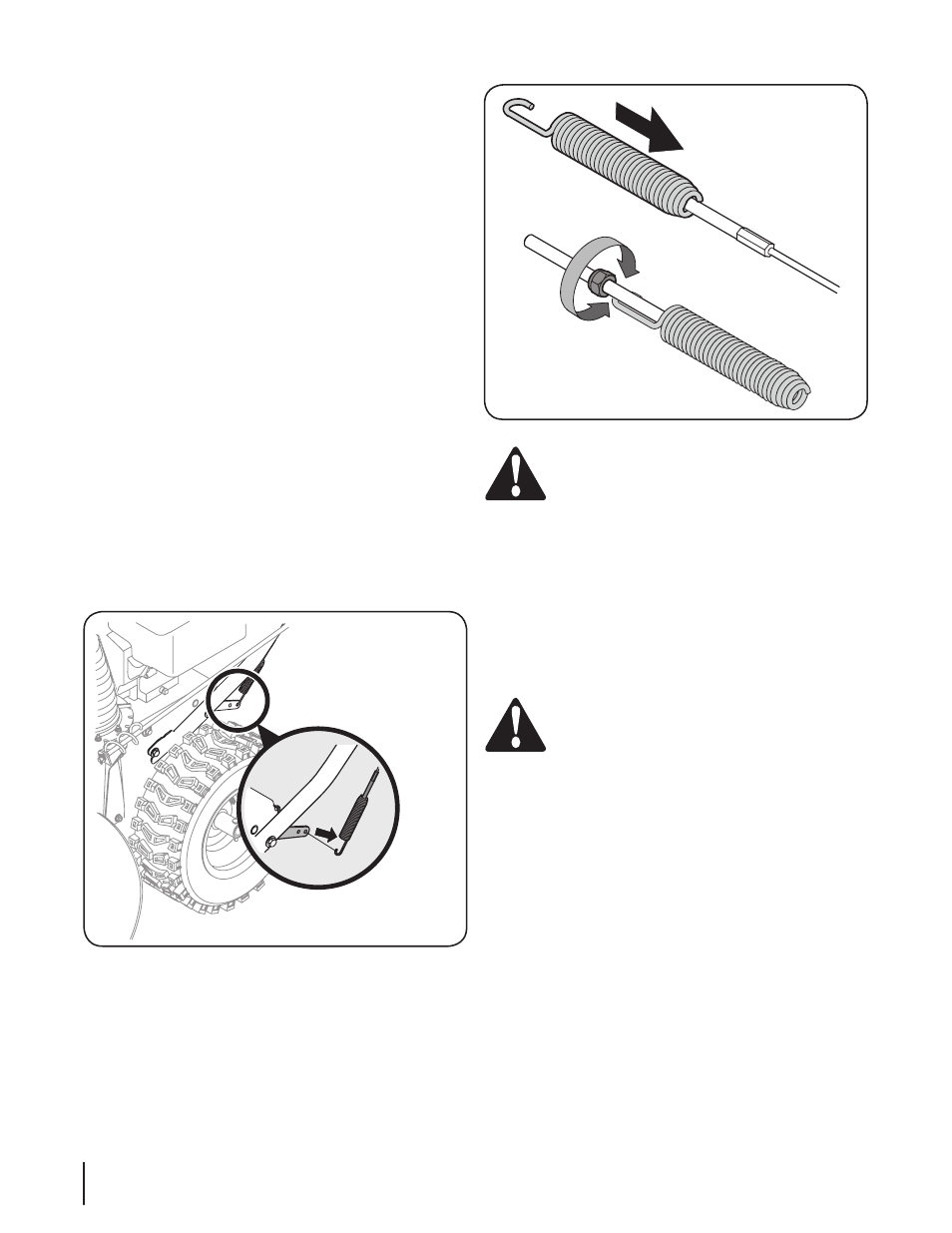

From beneath the handle, pull downward on the

1.

appropriate cable and unhook the spring found on the end

of the cable from its respective actuator bracket. Refer to

Figures 3-9 and 3-10.

Slide the spring up the cable to expose the cable coupler

2.

threads and lock nut. Refer to Figure 3-10.

Adjust the lock nut as follows: If adjusting the drive

3.

cable, thread the lock nut outward (down the coupler) to

lengthen the cable and allow the unit to move freely when

the control is released. Thread the lock nut inward (up

the coupler) to shorten the cable to reduce slippage and

prevent the machine from being easily moved with the

drive control engaged.

Figure 3-9

Figure 3-10

10

s

ectiOn

3— a

sseMbly

& s

et

-u

p