Great Planes Spectra ARF - GPMA1050 User Manual

Page 8

[127mm] long unthreaded wires and two 7" [178mm] long

threaded one end wires.

❏

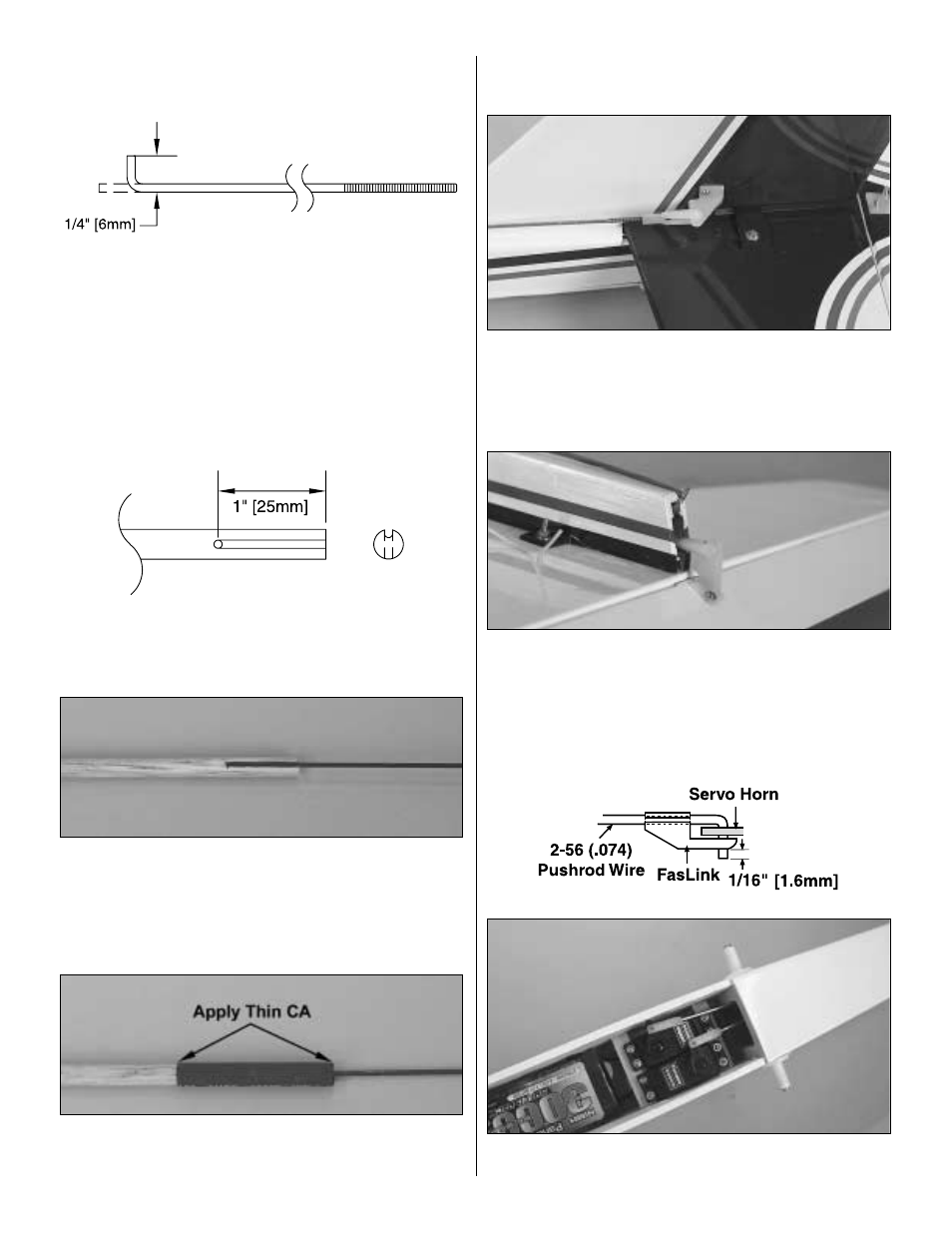

8. Make a 90° bend 1/4" [6mm] from the non-threaded

end in one of the threaded pushrod wires as shown in the

sketch. Make the same 90° bend in one end of the

remaining threaded and non-threaded pushrod wires. Wipe

off each wire using a paper towel dampened with rubbing

alcohol to remove any oil.

❏

9. Cut the pushrod dowels from the hardwood dowels.

The elevator pushrod dowel should be 12" [305mm] long.

The rudder pushrod dowel should be 10" [255mm] long.

❏

10. Drill a 5/64" [2mm] hole 1" [25mm] in from both ends

of each pushrod dowel. Cut a groove in each pushrod dowel

from the hole to the end of the dowel.

❏

11. Insert the 90° bend of one of the threaded pushrod

wires into one pushrod dowel. Insert the 90° bend of one of

the non threaded pieces of wire into the hole on the

opposite end of the pushrod dowel. Tack glue the wires in

place with a couple drops of CA. Repeat this procedure to

make the other pushrod.

❏

12. Use the heat shrink tubing at all the ends of each of

the pushrod dowels to hold everything in place as shown in

the photo. Use a heat gun to shrink the tubing. Apply a few

drops of thin CA to each end of the heat shrink tubing to

secure it.

❏

13. Install the rudder pushrod. Thread a clevis 14-turns

onto the pushrod. Attach the clevis to the control horn at the

4th hole from the inside. Bend the pushrod as necessary to

allow for free movement. Use a silicone retainer to secure

the clevis.

❏

14. Install the elevator pushrod. Center the elevator and

thread the clevis 14-turns onto the pushrod. Attach the

clevis to the control horn at the 4th hole from the inside. Trim

the opening at the rear of the fuselage as necessary to

allow the pushrod to move freely. Use a silicone retainer to

secure the clevis.

❏

15. Center the rudder and the rudder servo arm. Attach

a FasLink onto the pushrod in the radio compartment and

8