FloAire USI-FA User Manual

Page 4

SET SCREW TIGHTENING SCHEDULE

1. Before initial operation of the fan, tighten set screws

according to the procedure outlined below.

2. After 500 operating hours or three months, whichever

comes first, tighten set screws to the full

recommended torque.

3. At least once a year, tighten set screws to the full

recommended torque.

PROCEDURE FOR TIGHTENING SET SCREWS IN

BEARINGS AND HUBS

One Set Screw Application

Using a torque wrench, tighten the set screw to the

torque recommended in Table 1.

Two Set Screw Application

1. Using a torque wrench, tighten one set screw to half

of the torque recommended in Table 1.

2. Tighten the second set screw to the full recommended

torque.

3. Tighten the first set screw to the full recommended

torque.

VARIABLE FREQUENCY

DRIVES AND MOTORS

There are occasions when a Variable Frequency

Drive (VFD) will cause poor motor performance and

possible damage.

To avoid these problems, the

Company recommends the following:

1. Select compatible motor and VFD converter; if

possible, the motor and the converter should be

from the same manufacturer or at least the

converter selected should be recommended by the

motor manufacturer.

2. A motor shaft grounding system should be used to

prevent motor bearing damage from eddy currents.

NOTE:

The Company will not honor motor

warranty claims if the customer fails to follow

these recommendations.

Page 4

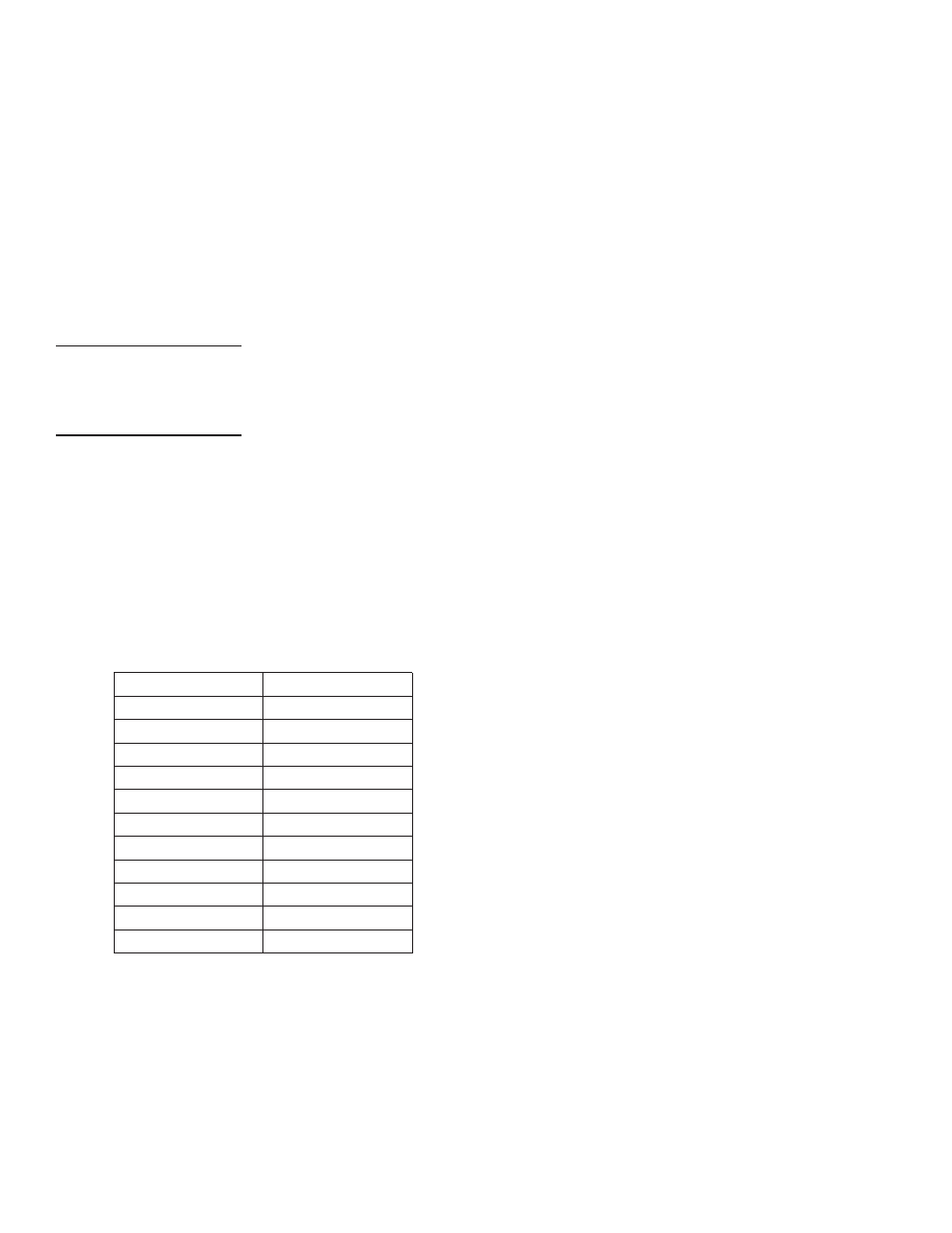

Table 1. Recommended Tightening Torque

for Set Screws

Set Screw Diameter

Torque (in-lbs)

#10

35

1/4

80

5/16

126

3/8

240

7/16

384

1/2

744

9/16

1080

5/8

1500

3/4

2580

7/8

3600

1

5400