Kawasaki engines – EDCO GS-42 User Manual

Page 6

b. Charge the battery or provide an absolute

source of 12 volt DC power capable of 50

amperes total output. (A pair of good

jumper cables from your car or truck battery

will suffice.) Equip yourself with an

inexpensive 12 volt test light.

c. If the trouble seems to be in the electrical

control equipment, you may wish to

disconnect the starter from the system so

as to check the system without spinning

the engine.

d. Battery rundown. A common problem

is letting the battery run down. What

usually happens is that it takes the crew a

few jobs to get used to the whole system,

so the machine is stopped and started

quite often. Key left in on position, when

engine is turned off, will result in battery

running down – dying.

D. Belt Inspection & Replacement

Inspection

• Fold T-Handle to forward position

• Tilt machine back on rear of body & handle

• If belt is worn, cracked or shredding, belt

needs to be replaced.

Replacement

• Place 3/4" wrench on end of the shaft on the

top of the buffer body.

• Turn pad driver counter-clockwise to

remove.

• Take belt off by turning 3/4" wrench on shaft

and removing belt from pad driver pulley

and engine crank pulley.

• Check pad driver pulley & engine crank

pulley for correct alignment.

• Install new belt on engine crank pulley &

pad driver pulley, using 3/4" wrench.

• Install belt on tension pulley

• Install pad drive onto shaft, and return

buffer to operating position.

E. Adjusting Pad Pressure

The pad pressure may be adjusted by moving

the wheels:

• Forward to reduce weight on the buffer pad

or

• Backward to increase the weight

This adjustment may be required to adjust to

different floor finishes or to the weight variance

of aluminum or steel propane tanks.

KAWASAKI ENGINES

Tune-up Specifications

ITEM

SPECIFICATIONS

Ignition Timing

Unadjustable

Spark Plugs:

NGK - BPR4ES

Gap

0.75 mm (0.30 in)

Low Idle Speed

1500 RPM

High Idle Speed

3400 RPM

Valve Clearance

IN: 0.10-0.15 mm

(0.004-0.006 in)

EX: 0.10-0.15 mm

(0.004-0.006 in)

Other

No other adjustment

Specifications

needed

NOTE: High and low idle speeds may vary

depending on the equipment on which the engine

is used. Refer to the equipment specifications.

Engine Oil

Check the engine oil daily before starting the

engine otherwise shortage of the engine oil may

cause serious damage to the engine such as

seizure.

• Place the engine on a level surface. Clean the

area around the oil gauge before removing it.

• Remove the oil gauge and wipe it with a

clean cloth.

• Pour the oil slowly to “FULL” mark on the oil

gauge.

• Insert the oil gauge into the tube WITHOUT

SCREWING IT IN.

• Remove the oil gauge to check the oil level.

The oil level should be between “ADD” and

“FULL” marks. Do not overfill.

• Install and tighten the oil gauge.

The following engine oils are recommended:

API Service Classification: SF, SG, SH, or SJ.

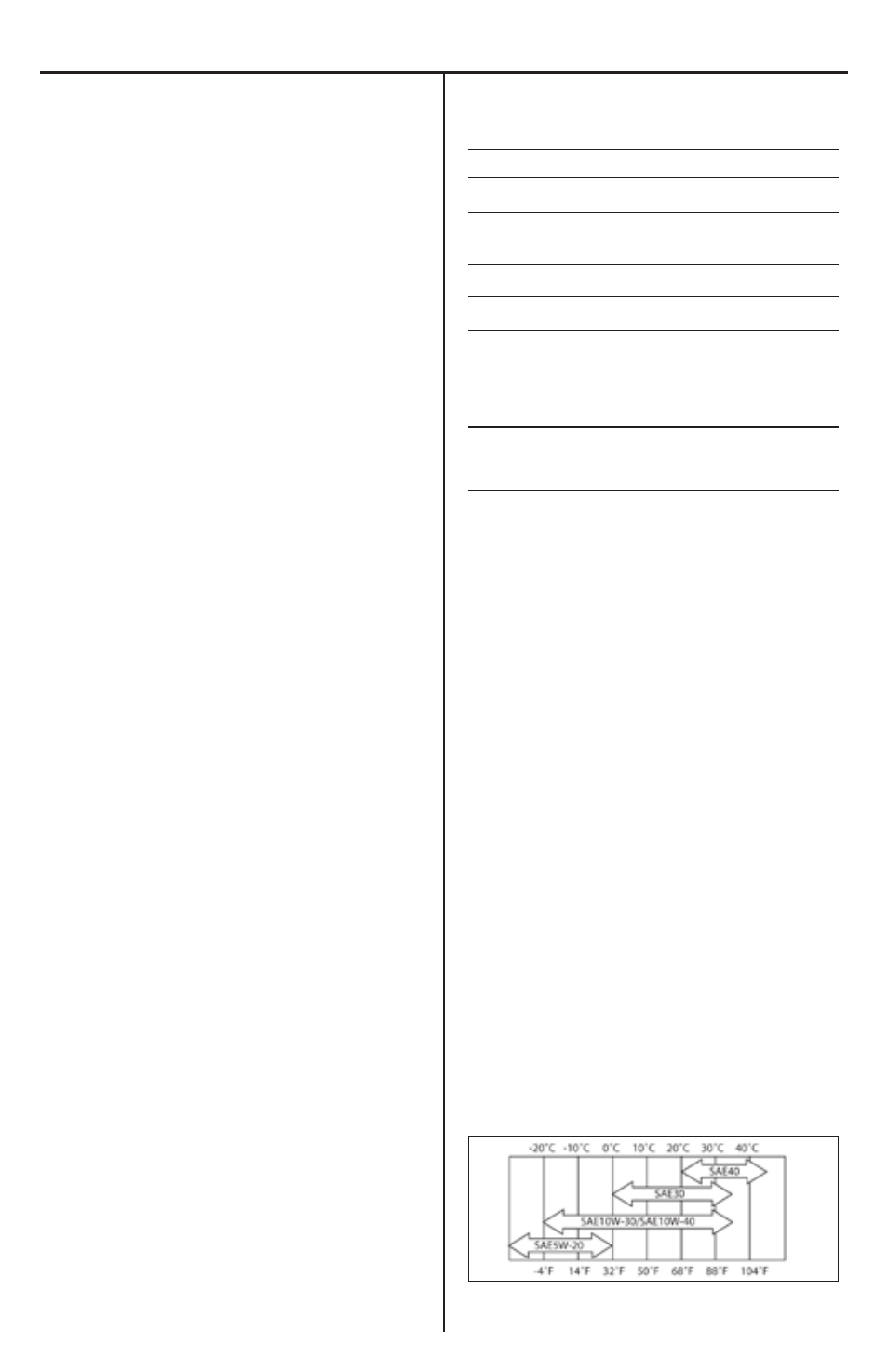

Oil Viscosity

Choose the viscosity according to the

temperature as follows:

NOTE: Using multi grade oils (5W-20, 10W-30, and 10W-40)

will increase oil consumption. Check oil level more frequently.

PG. 6