Vi. cart puller capacity – COMEUP Electric Winch (Ver:02) User Manual

Page 15

VI. Cart Puller Capacity

13

Choose the Right Winch

In most pulling applications you are dealing with a rolling road rather than pulling a dead

weight. Resistance to rolling is mostly influenced by the load, rolling resistance, track gradient,

track curvature, track conditions.

● Load: Calculate the total weight of the loaded cart to be moved simultaneously.

● Rolling resistance: Resistance to rolling is influenced by the wheel journals, type of

lubrication used and the ambient temperature.

● Track gradient: For each one percent gradient, a rise of one meter for every 100 meter of

track, the running line pull must be increased by 10 kg per ton.

● Track curvature: To overcome the effects of wheels binding against rails on curved sections

of track, running line pull must be increased. For each degree of curvature,

the running line pull must be increased by 1kg per ton.

● Track conditions: The condition of substandard track can vary considerably.

Application Condition Example

1).Pulling of a rolling cart in and out of an oven using a single wire rope

2).50 ton total load being moved included weight of cart

3).Steel cart wheels with precision wheel bearing

4).New track, 5curvature and 2% gradient

Pulling Capacity Required

50 ton…..…….….………Total weight being moved

x (10 kg+20 kg+5 kg) 10kg…......Pull required per ton being moved

1,750 kg 20kg…......For each one percent gradient, the running line pull

must be increased by 10 kg/ton

5kg……......For each one degree of curvature, the running line

pull must be increased by 1 kg/ton

x 1.2 20%…….. contingency for unpredictable track or cart conditions

2,100 kg …..…...........Minimum calculated cart puller capacity

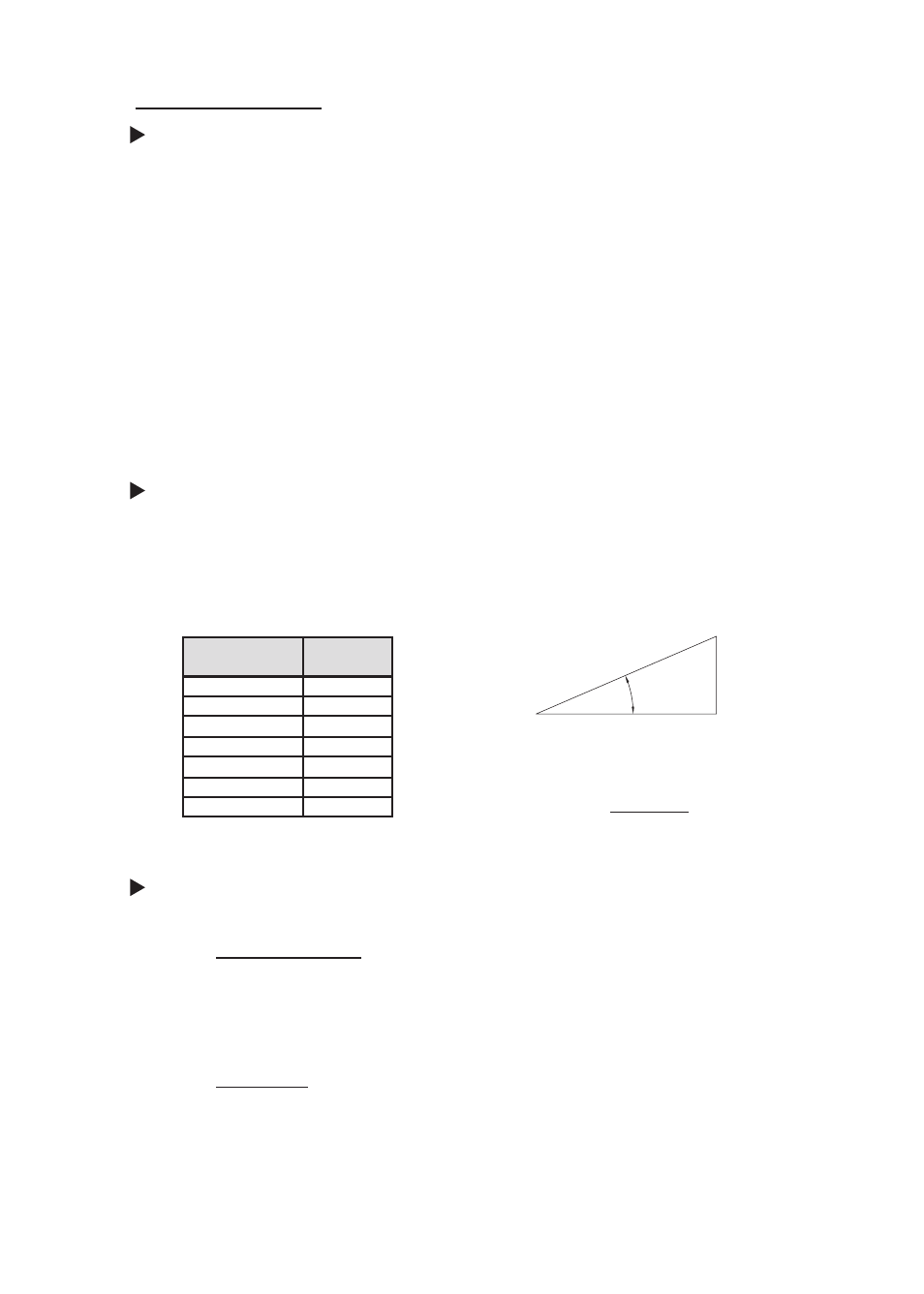

5%

3°

10%

6°

20%

11°

30%

17°

50%

26°

70%

35°

100%

45°

Gradient (%) = X 100 (%)

Height

Distance

Gradient

Gradient

Percentage

Gradient

Height

Distance

A gradient of 10% is a rise of one meter in ten meters