Vi. maintenance – COMEUP Utility Duty Winch (Ver:00) User Manual

Page 11

VI. Maintenance

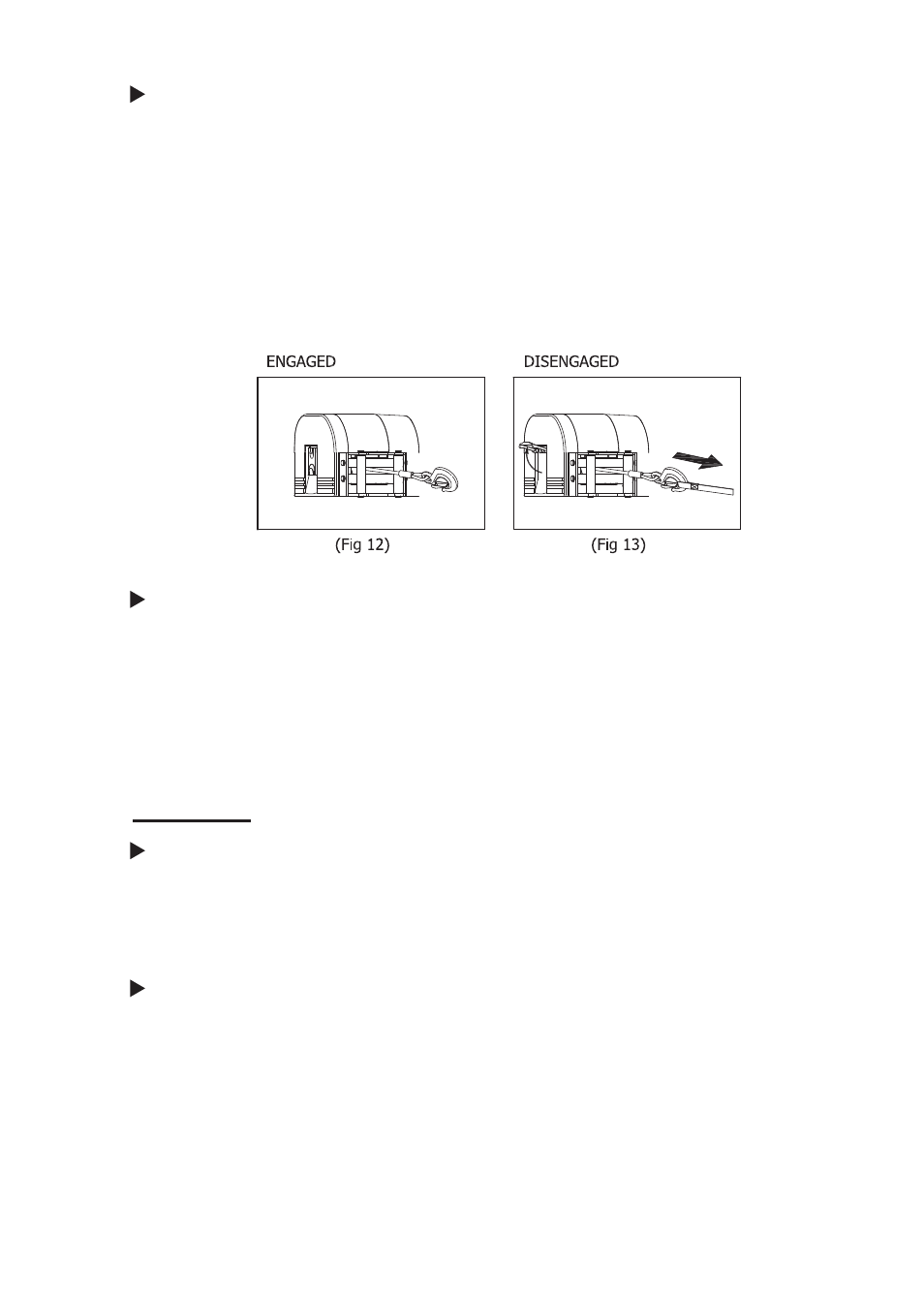

The free-spool allows rapid wire rope payout for hooking onto the load or anchor points

and is operated by a free-spool level.

The free-spool level must be in the “Engaged” position before winching (fig 12)

1). To disengage the free-spool by lifting a free-spool lever in the “Disengaged” position, wire

rope can now be free spooled on the drum (fig13)

2). To engaged the free-spool, press a free-spool level in the “Engaged” position.

3). If a free-spool lever can’t be properly locked in the “Disengaged” position, rotate the drum

to make the pole free-spool to couple the gear train completely.

4). Wear leather gloves and use a handsaver strap when guiding the wire rope out of the drum.

9

Clutch Function

The proper usage of a snatch block will nearly double the capacity of the winch but the

speed will decay 50%.

It is recommended to use snatch block for loading over the rated load.

When a snatch block is applied, be sure that the anchor point of the hook is secured to

withstand the double line rated capacity of the winch.

Use a Snatch Block Assembly

All moving parts in the winch are permanently lubricated at the time of assembly. Under

normal conditions factory lubrication will suffice. If re-lubrication is necessary after repair or

disassembly only use marine type grease.

Lubrication

Never substitute a heavier or lighter wire rope. Never use rope made of any material other

than wire.

1). Spool the entire wire rope, then cut and take it out from the drum.

2). Put the replacement wire rope through the fairlead opening, pass below the drum, and

insert it into the hole of drum core.

3). Tighten the screw downwards to secure the wire rope(fig14).

4). Secure the wire rope to the hook with 2 sets of cable clip, tighten the screw completely (fig 15).

Wire Rope Replacement