Auxiliary controls, S87d control module, Q347a spark igniter-sensor – Honeywell Y343B1002 User Manual

Page 4: Installation, Caution

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

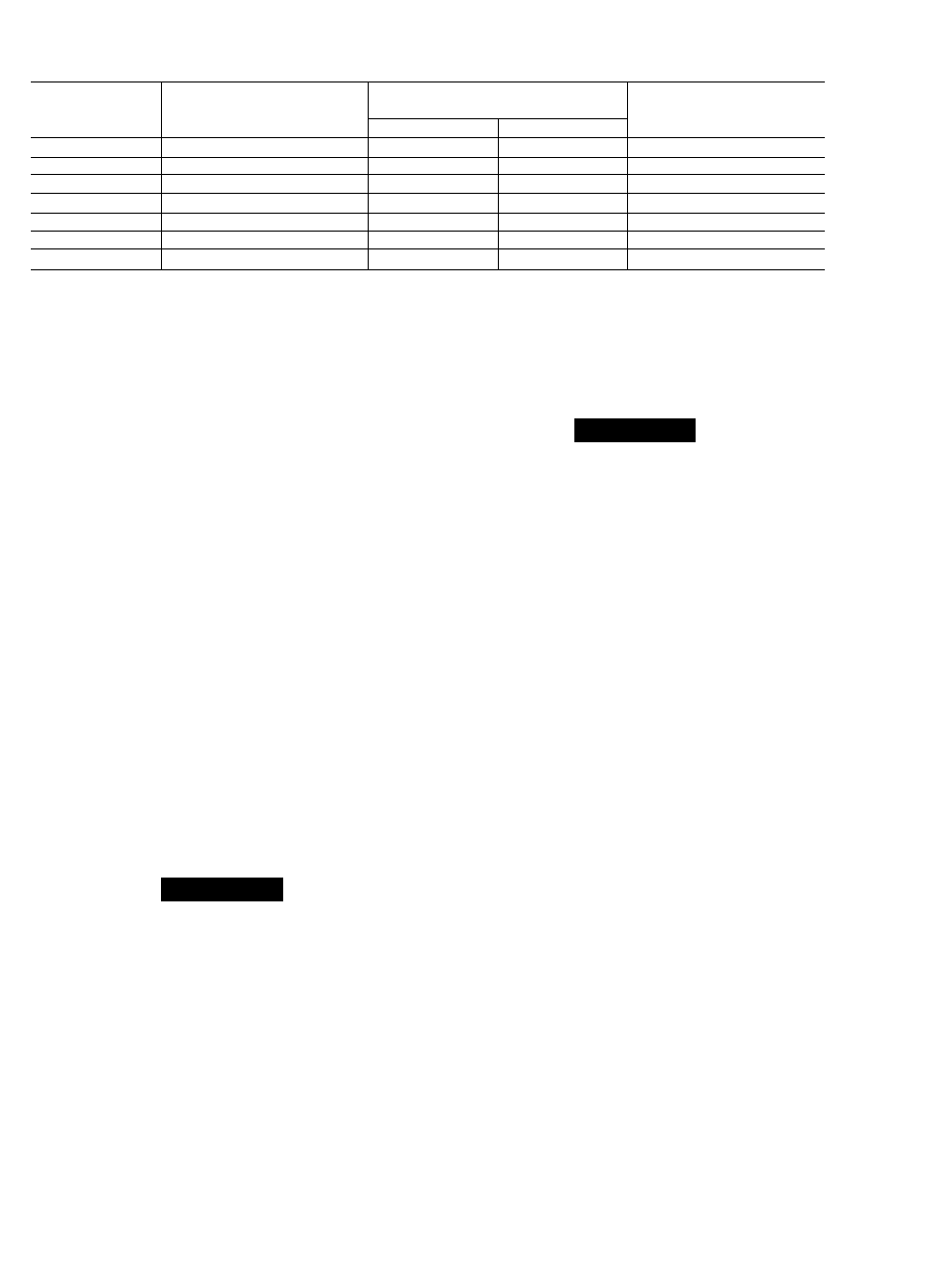

TABLE 1—GAS CONTROLS.

MODEL NO.

TYPE OF PRESSURE

REGULATOR

CAPACITY RANGE OF

STANDARD MODEL

PUBLICATION FORM

NUMBER

cfh

mVhr

V845A

Standard

noto 335

3.1 to 9.5

60-2315

VR8450A

Standard

noto 290

3.1 to 7.8

68-0016

V845C

Step-open

noto 335

3.1 to 9.5

60-2315

VR8450C

Step-open

noto 290

3.1 to 7.8

68-0016

VR8540A

Two-stage

noto 290

3.1 to 7.8

68-0021

VR8590A

Negative

37 to 400

I.Oto 11.3

68-0017

VR8600A

Negative

37 to 400

I.Oto 11.3

68-0017

AUXILIARY CONTROLS

REQUIRED FOR BASIC DSI SYSTEM

1. TRANSFORMER. Select transformer with ade

quate VA. S87D requires a 24 Vac transformer. For

common system transformers, capacity must be ade

quate for S87D, temperature controller, gas control and

any other device powered by the transformer (see

Table 2).

2.

LOW VOLTAGE TEMPERATURE CONTROLLER.

Select a 24 Vac thermostat for single-stage or

two-stage burner control (depending on heating sys

tem).

DETERMINED BY PARTICULAR APPLICATION

Refer to separate publications for information on the

controls utilized by the appiiance manufacturer. These

controis are:

1. High iimit temperature controlier and other safety

controis as required.

2. Gas vaive. Refer to Tabie 1 above.

3. Alarm signal as desired for the circuit under

control of the S87D.

CAUTION

1. When using a common transformer to power

both S87D and gas control circuit, use a good

quality transformer of adequate VA. If trans

former VA is inadequate, the S87D internal

relay may chatter.

2. When two or more transformers are used, they

must be properly phased and grounded.

INSTALLATION

WHEN INSTALLING THIS IGNITION PACKAGE. ..

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on

the product to make sure it is suitable for your

application.

3. The installer must be a trained, experienced

service technician.

4. After installation is complete, check out system

operation.

CAUTION

1. Disconnect power supply before wiring to pre

vent electrical shock or equipment damage.

2. If a new gas control is to be installed, turn off

gas supply before starting installation. Be sure

to conduct a Gas Leak Test after the gas

control is installed (follow manufacturer’s

instructions).

IMPORTANT-

If this is a replacement application, follow the

appliance manufacturer’s instructions. The manu

facturer

usually

provides

wiring

diagrams,

start-up and checkout instructions and service

procedures for their system. If manufacturer’s

instructions are not available, the information

below may be used as a general guide.

S87D CONTROL MODULE

Select a location within 30 in. [762 mm] maximum of

the burner that will permit a direct cable route to the

Q347A spark igniter. Ready access to the terminals is

necessary for wiring and servicing. Do not exceed the

ambient temperature rating given in the SPECIF

ICATION section.

The S87 may be mounted in any position. See Fig. 1

for mounting dimensions. Use No. 6-32 machine screws

or No.

8

sheetmetal screws 1 in. long for fastening.

Fasten securely.

Q347A SPARK IGNITER-SENSOR

The Q347A should be rigidly mounted in an ac

cessible location. It must remain in a fixed position

relative to the main burner. The Q347 may be mounted

on a separate bracket or on the same bracket with the

Q354A Flame Sensor. On multiple burners, the 0347

may be mounted at one end of the row and the 0354 at

the other end to delay spark cutoff until all burners are

ignited.

IMPORTANT-

The ignition cable limits the distance between the

0347 and S87 to 30 in. [762 mm] or less. This may

affect the location selected for the 0347 and/or

S87. Ignition cable must not touch grounded

object or current-carrying wires.