Flexible capillary model, Wiring, Replacement of similar device by the l4017 – Honeywell L4017 User Manual

Page 4: Caution

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

5. Insert the element into the element opening and

slip the asbestos washer over the capillary (Fig. 4).

With the 2 screws provided, securely fasten the control

to the furnace casing.

6. Position the element as described in Location

above, bending as necessary. Avoid sharp bends or

repeated flexing with the self-supporting model (Fig. 2).

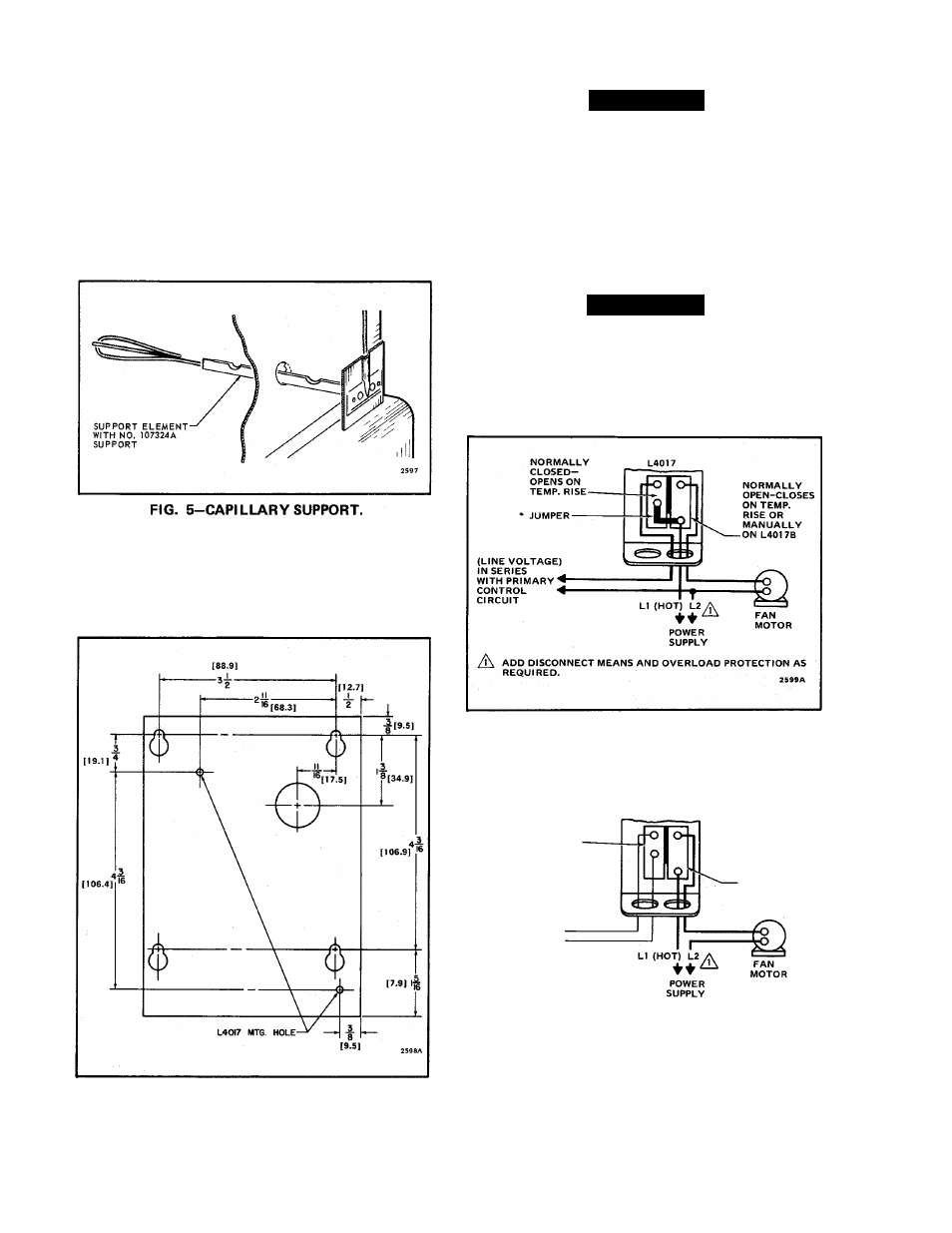

FLEXIBLE CAPILLARY MODEL

The element must be firmly held in position by use

of capillary support. Part No. 107324A, or similar

support (Fig. 5).

WIRING

REPLACEMENT OF SIMILAR DEVICE BY THE

L4017

Adapter plate bag assembly. Part No. 21136E, is

available to fit mounting holes of similar controls

(Fig. 6).

CAUTION

Disconnect power supply before connecting wiring

to prevent electrical shock or equipment damage.

All wiring must comply with applicable local codes

and ordinances. Follow the system wiring diagrams

furnished with the burner. Figs. 7 and 8 illustrate the

connections to the L4017. For ease in wiring, 2 conduit

knockouts are furnished at the bottom, and 1 at the top

of the case.

CAUTION

A jumper is provided between the fan and the

limit terminals. This jumper is used when both the

fan and the limit switches are switching line voltage

circuits. When the high limit switch is used in the

low voltage circuit, remove this jumper.

FIG. 7-CONNECTIONS TO L4017 WITH LIMIT

SWITCH IN LINE VOLTAGE CIRCUIT (JUM

PER IN PLACE).

NORMALLY

OPEN-CLOSES

ON TEMP.

RISE OR

MANUALLY

ON L401 78

NORMALLY

CLOSED-

OPENS

ON TEMP. RISE

(LOW VOLTAGE)

IN SERIES

WITH PRIMARY^

CONTROL *4

CIRCUIT

ADD

DISCONNECT

MEANS AND

OVERLOAD

PROTECTION

AS

REQUIRED.

2600B

FIG. 6-ADAPTER PLATE AND DIMENSIONS, IN

INCHES [MILLIMETERS IN BRACKETS].

FIG. 8-CONNECTIONS TO THE L4017 WITH LIMIT

SWITCH IN LOW VOLTAGE CIRCUIT (JUM

PER REMOVED).

Page

4