Installation wiring diagrams operation – Chromalox PQ431 User Manual

Page 3

CAUTION: Hazard of Electric Shock. The vaporizer

must be grounded using the grounding means pro-

vided in the heater terminal box and in the control

box, and employ wiring in accordance with the

National Electrical Code.

1. The vaporizer is normally supplied one of three different ways:

A. Without controls as they are going to be provided by the

customer. The customer will have to wire from his supplied

controls to the level or float switch on the vessel, and to the

heater terminal blocks and the ground lug in the heater ter-

minal enclosure.

B. With controls supplied, but mounted remotely by the user.

The customer will have to wire from remote controls to the

level or float switch on the vessel, and to the heater terminal

blocks and the ground lug in the heater terminal enclosure.

C. With all controls mounted on the same skid with the

hydraulic or mechanical part of the vaporizer. The unit is

completely wired. The only wiring necessary is to terminals

L1, L2 and L3 on the main circuit breaker and the ground-

ing lug in the control panel.

2. Note: All electrical connections should be checked and tight-

ened if necessary. These sometimes loosen in transit.

CAUTION: Hazard of Electric Shock. Disconnect all

power before servicing the vaporizer.

INSTALLATION

WIRING DIAGRAMS

OPERATION

CAUTION: To avoid possible damage to the heaters, do not ener-

gize the heaters until the vaporizer is filled with fluid.

1. The filling of the Chromalox CHTV type horizontal vaporizer

is accomplished in one of two ways:

A. On vaporizers with gravity return type condensate return

systems, the filling is done simply by pouring the heat

transfer or other organic media into the vaporizer shell

using the spare or fill nozzle and, while the filling is taking

place, bleeding the displaced air from the vent.

B. On vaporizers that use pump condensate return systems or

on systems where the condensate is not returned, the filling

would be done by first filling the condensate return tank or

supply or reservoir tank and then energizing the condensate

return or supply pump. While the vaporizer vessel is being

filled, the vent nozzle should be opening for bleeding out

the air.

2. Set the thermostat at 220°F and/or the controlling pressure

switch at its equivalent.

3. To energize the heaters, turn the “on-off” selector switch to the

“on” position. The heaters are interlocked with the level or

float switch located on the vessel, so that the heating element

will shut off automatically in case of a low liquid level.

4. Operate the vaporizer until 220°F is reached. Periodically open

the bleed valves to remove air from the system. At 220°F any

moisture that has been trapped in the system will flash into

steam and can be bled off through the bleeder valves.

WARNING: Avoid having the heat transfer fluid or the fluid to be

vaporized spilled or leaked into the pipeline or vessel insulation as

it has been found that spontaneous ignition of some of these fluids

may result at elevated temperatures.

5. After the vaporizer has been completely charged and free of

steam pockets, set the controlling pressure switch or thermostat to

the pressure or temperature point where the fluid will vaporize.

6. Operate the vaporizer until this set point is reached.

Periodically open the bleeder valves to remove air from the

system.

7. After the system is completely free of air, set the controlling

pressure switch or thermostat to the desired operating point.

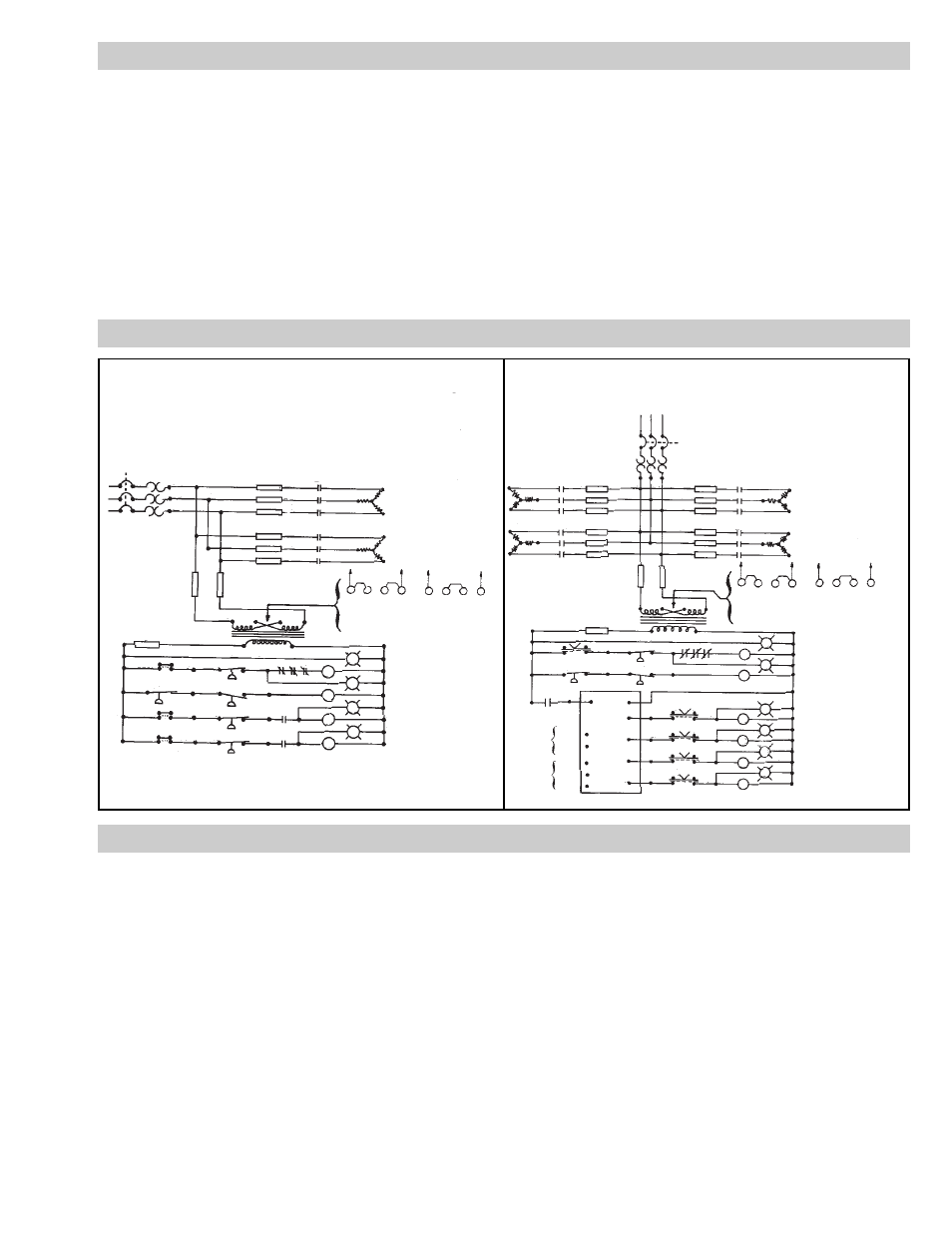

Circuit

Breaker

Circuit

Breaker

L1

L2

L3

C1

C2

F1

F2

F3

F4

F5

F6

H4 H2 H3 H1

H4 H2 H3 H1

F8

F7

H4

H2

H3 H1

X1 120-Volt X2

240V 480V

Transformer Primary

Pilot Light

Feed or Condensate

Return Pump (Optional)

Pilot Light

High Limit Circuit

Pilot Light

Heat #1

Pilot Light

Heat #2

Off On

Off On

Off On

3

5

7

10

4

6

8

11

9

12

M

CR

C1

C2

1CR

1CR

R

G

A

A

F9

OPC

FS2

FS-1

PSI-1

PSI-2

H4 H2 H3 H1

H4 H2 H3 H1

240V 480V

Transformer Primary

Off On

C1

C2

C3

C4

L1

L2 L3

F1

F2

F3

F4

F5

F6

F7

F8

F9

F10

F11

F12

F13

F14

H4

H3

H2

H1

F15

34

5

6

X1

X2

FS2

FS1

OPC

4-20MA

Input

135 ohm

Input

Stepper

X1

X2

A+

B-

C

D

E

1

2

3

4

1CR

1CR

Off On

Off On

Off On

Off On

7

8

9

10

11

12

13

14

15

M

R

G

A

C1

C2

C3

C4

A

A

A

Pilot LIght

Feed or Condensate

Return Pump (Optional)

Pilot Light

Low Level and

High Limit Circuit

Pilot Light

Heat #1

Pilot LIght

Heat #2

Pilot LIght

Heat #3

Pilot LIght

Heat #4

Typical Wiring Diagram

15 to 100 kW (All Voltages)

Typical Wiring Diagram

125 to 300 kW 440/480 and 550/575V