Caution, Assembly, Assembling the winch – Champion Power Equipment 14001 User Manual

Page 9: Contactor/solenoid location, Installing the rocker switch

REV 14001-20120829

6

14001

ENGLISH

asseMbly

assembling the Winch

This CPE 4000 lb . (1814 kg .) winch is designed

with a bolt pattern that is standard in this class

of winch . Many winch mounting kits are available

that utilize this bolt pattern for the most popular

UTVs and ATVs . If you cannot find a kit locally,

contact CPE and we will provide you with the

name of a dealer .

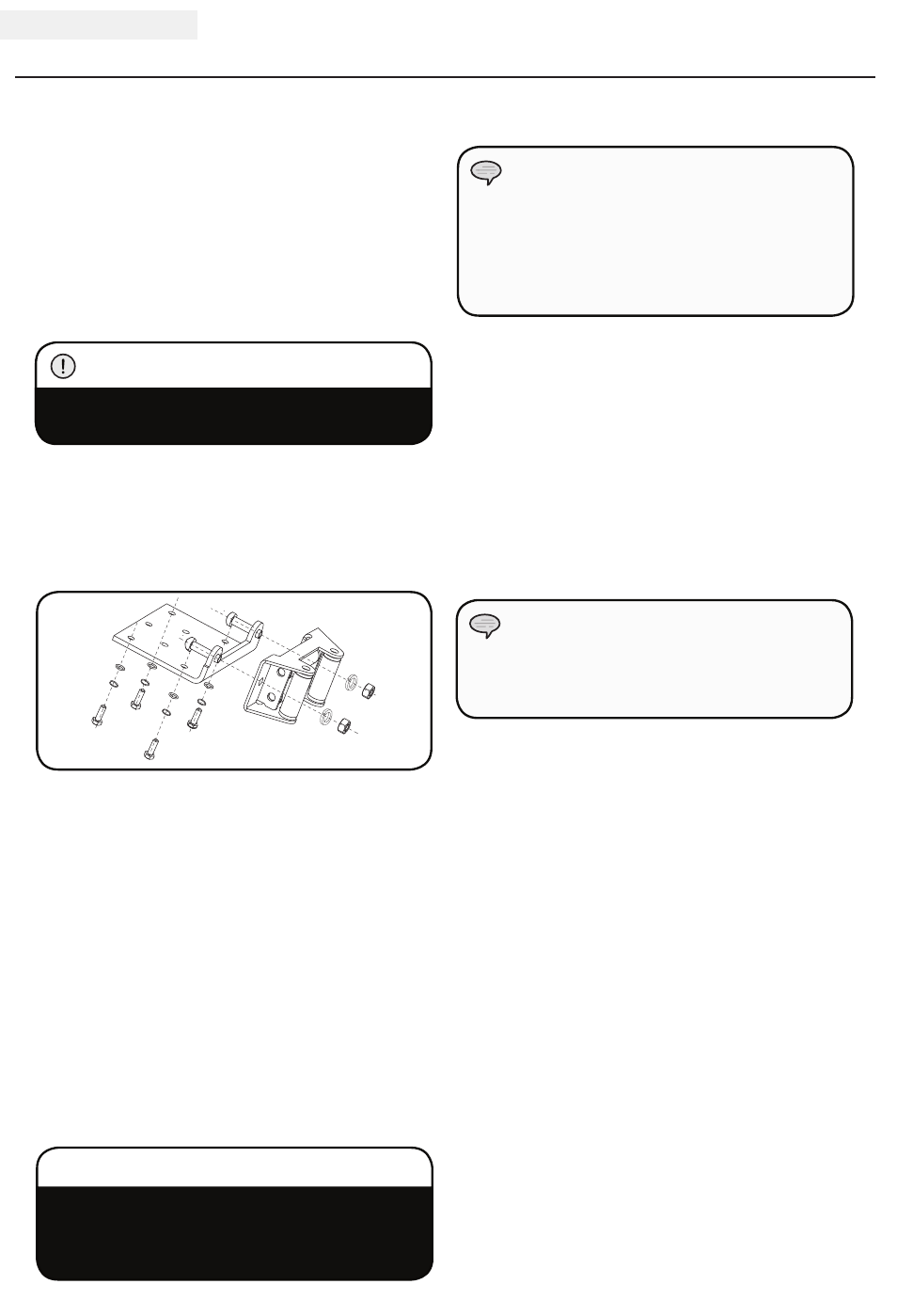

1 . Insert M10x20 bolts through the mounting

channel holes and attach the roller fairlead

to the mounting channel with the M10 lock

washers and M10 nuts provided .

2 . Turn the winch upside down . Place the

mounting channel on the winch, making sure

the winch is centered in the middle of it .

3 . Thread the M8x25 bolts through the M8 flat

and lockers washers, and then thread through

the mounting channel . Tighten the bolts . DO

NOT over tighten .

4 . Turn winch right side up . Disengage the

clutch by moving the Cam Ring to the “Out”

position . Release the wire rope and pull

through the roller fairlead .

5 . Attach the clevis hook to the cable, and then

hand strap to the clevis hook .

The type of vehicle to which the winch and

mounting channel will be applied, will dictate

the type of mounting kit that should be used

(Speed Mount™ Hitch Adapter, Standard

Mounting Channel, or Specialty Mounting Kit) .

noTe

If utilizing a mounting plate, ensure that the three

major sections (motor, drum and gear housing) are

properly aligned . Proper alignment of the winch will

allow for even distribution of the full rated load .

CaUTIon

Mounting bolts must be SAE grade 5 or better

and torque to 34 ft . lbs .

CaUTIon

assembling the Winch Cont’d.

Contactor/solenoid location

Find a location for the contactor/solenoid . It is

recommended that the contactor/solenoid be

mounted close to the battery in a clean, dry

location . Make sure the location chosen allows for

sufficient clearance from all metal components .

Drill mounting holes if required . Once a location

is found, DO NOT install the unit until all wiring

is completed (see wiring section) .

Installing the rocker switch

1 . Decide which handlebar the rocker switch will

be mounted on . (The rocker switch is usually

installed on the left handlebar) .

2 . Use a piece of electrical tape (not provided)

around the handlebar to help prevent rotation

of the mount .

3 . Tighten the rocker switch in place . DO NOT

over tighten or tighten/clamp over any hoses

or cables .

4 . Once the rocker switch is mounted, the wires

can be routed back to where the contactor/

solenoid is located .

5 . Make sure the handlebars have full range of

motion and then secure the rocker switch’s

cable with the supplied cable ties .

Terminals coming in contact with metal will cause

a direct short, possibly causing contactor/solenoid

and/or battery damage .

noTe