Torque-limiter clutches, Martin, Torque limiter – CAMCORP SWF with Externally Mounted Fan User Manual

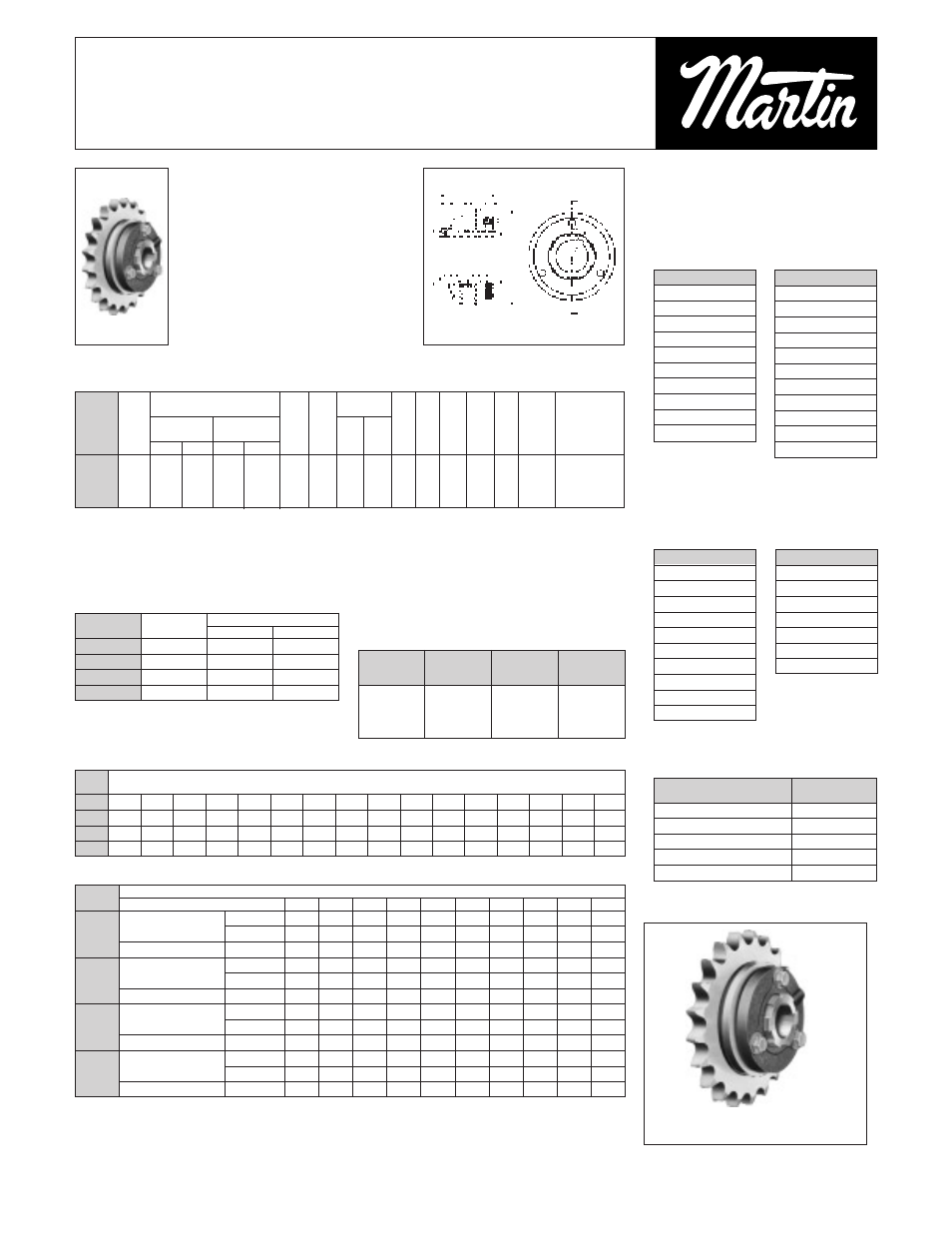

Page 38: Torque-limiter clutch ratings, Bored to size torque limiters w/std. kw & i-ss

3

Torque-Limiter

Clutches

Stock Plate Sprockets with Ground

Face and Bored to Fit the

Martin

Torque Limiter

Sprocket Size

35TTA25-25

35TTA26-25

40TTA20-25

40TTA22-25

40TTA24-25

40TTA28-25

40TTA30-25

50TTA17-25

50TTA21-25

50TTA22-25

Sprocket Size

35TTA35-35

35TTA40-35

40TTA28-35

40TTA30-35

40TTA32-35

50TTA22-35

50TTA24-35

50TTA25-35

50TTA26-35

60TTA18-35

60TTA20-35

TT25 1 300

700

400

1200

2

1

⁄

2

1

3

⁄

4

1

⁄

8

11

⁄

32

29

⁄

64

19

⁄

64

19

⁄

64

2

1

⁄

2

1

1

⁄

2

1.368 1.631/1.628

TT35 2.5

600 1700

900

2500

3

1

⁄

2

2

7

⁄

16

1

⁄

8

5

⁄

8

45

⁄

64

23

⁄

64

35

⁄

64

3

3

⁄

16

1

15

⁄

16

1.675 2.006/2.003

TT50 6 950

2650

2350

5700

5 2

7

⁄

8

1

⁄

8

5

⁄

8

53

⁄

64

29

⁄

64

21

⁄

32

4

5

⁄

16

2

13

⁄

16

2.625 3.008/3.005

TT70 18 2100

8000

3100

11500 7 3

7

⁄

8

1

⁄

4

1

1

⁄

4

55

⁄

64

31

⁄

64

29

⁄

32

6 4

3.811

4.197/4.194

Torque Rating ▲

C

K

L

(Pound-Inches)

+.000

+.003

With One

With Two

–.002

–.000

Size

Avg.

Spring

Springs**

G

Spline

Spkt.

No.

Wt.

Min. Max. Min. Max

A

B

Min. Max. D

E

♦

H

J

O. D.

Bore

Torque-Limiter Clutch Ratings

TT25

1

⁄

2

7

⁄

8

1

TT35

3

⁄

4

1

3

⁄

16

1

1

⁄

4

TT50

1

1

3

⁄

4

2

TT70 1

3

⁄

8

2

3

⁄

4

3

Size

Stock

Max. Bore

No.

Bore

Std. KW*

Shallow KW*

1

⁄

2

-

9

⁄

16

1

⁄

8

Ч

1

⁄

16

1

7

⁄

16

-1

3

⁄

4

3

⁄

8

Ч

3

⁄

16

5

⁄

8

-

7

⁄

8

3

⁄

16

Ч

3

⁄

32

1

13

⁄

16

-2

1

⁄

4

1

⁄

2

Ч

1

⁄

4

15

⁄

16

-1

1

⁄

4

1

⁄

4

Ч

1

⁄

8

2

5

⁄

16

-2

3

⁄

4

5

⁄

8

Ч

5

⁄

16

1

5

⁄

16

-1

3

⁄

8

5

⁄

16

Ч

5

⁄

32

3

13

⁄

16

-3

3

⁄

4

Ч

3

⁄

8

Torque-

Torque-

Limiter

Limiter

Bore

Keyway

Bore

Keyway

TT25

1

⁄

2

5

⁄

8

3

⁄

4

7

⁄

8

TT35

3

⁄

4

7

⁄

8

1

TT50

1

1

1

⁄

8

1

3

⁄

16

1

1

⁄

4

1

3

⁄

8

1

7

⁄

16

1

1

⁄

2

1

5

⁄

8

TT70

1

7

⁄

16

1

1

⁄

2

1

3

⁄

4

1

15

⁄

16

2 2

7

⁄

16

Size

No.

Finished Bores

STK.

Ͼ

25 19 19 16 .. .. .. .. .. ..

TT25 Min. Teeth

MTO

25 19 19 16 .. .. .. .. .. ..

Bush. Lght. Req’d.

1

⁄

8

1

⁄

8

1

⁄

4

1

⁄

4

.. .. .. .. .. ..

STK.

Ͼ

35 25 26 21 18 15 .. .. .. ..

TT35 Min. Teeth

MTO

33 25 26 21 18 15 .. .. .. ..

Bush. Lght. Req’d.

1

⁄

8

1

⁄

8

1

⁄

4

1

⁄

4

3

⁄

8

3

⁄

8

.. .. .. ..

STK.

Ͼ

48 35 35 29 25 19 .. .. .. ..

TT50 Min. Teeth

MTO

46 35 35 29 25 19 .. .. .. ..

Bush. Lght. Req’d.

1

⁄

8

1

⁄

8

1

⁄

4

1

⁄

4

3

⁄

8

3

⁄

8

.. .. .. ..

STK.

Ͼ

.. ..

48

38

33

26

21

18

16

14

TT70 Min. Teeth

MTO

.. ..

48

38

33

26

21

18

16

14

Bush. Lght. Req’d.

..

..

1

⁄

4

1

⁄

4

3

⁄

8

3

⁄

8

1

⁄

2

7

⁄

8

Ͼ

7

⁄

8

Ͼ

1

Unit

Min. Allowable Sprocket Teeth and Length of Bushing Req’d for Chain Number

Size

Sprocket Pitch

35

41

40

50

60

80

100

120

140

160

★

Min. number of teeth on sprocket stocked by factory which can be used w/Torque-Limiter clutch.

Min. number of teeth on made-to-order sprocket which will permit chain to clear friction disc.

* Use one

3

⁄

8

″

long bushing and one

1

⁄

2

″

long.

♦

Use two

1

⁄

2

″

long bushings.

† KW Same as Std. Listed in Tables Above. Additional S.S. See List Price

Bored to Size Torque Limiters w/Std. KW & I-SS

†

† Additional SS See List Price Alterations

* KW To Be Cut Central w/Threaded Spline

Standard Keyways

Stock Bores — Torque Limiters (No KW I-SS

†

)

▲

Using a center member with rubbing sides ground

parallel — 65 to 125 micro-inches. Center member

must be clean and free from oil, rust, etc.

** Second spring may be nested in one originally fur-

nished. Order if required.

♦

Nominal for maximum torque setting. For minimum

torque setting, add

3

⁄

64

for No. 25;

5

⁄

64

for No. 35;

3

⁄

32

for

Nos. 50 and 70. When two springs are used this

dimension is increased approximately

1

⁄

16

″

on Nos.

25, 35 and 50 —

3

⁄

32

″

on No. 70.

TORQUE-LIMITER CLUTCHES

Each assembled unit contains one

spring. Higher ratings can be obtained

by ordering a second spring to nest in

the original one. Bushings need to be

ordered separately if required.

The rubbing sides of the center

member should be ground parallel —

65 to 125 micro-inches.

Sprocket Size

40TTA35-50

50TTA30-50

50TTA32-50

60TTA25-50

60TTA26-50

60TTA28-50

60TTA30-50

80TTA20-50

80TTA22-50

80TTA24-50

Sprocket Size

60TTA36-70

80TTA26-70

80TTA28-70

80TTA30-70

80TTA36-70

100TTA22-70

100TTA24-70

PRESSURE PLATE

2

FRICTION DISC

2

ADJ. NUT ASSY. & S.S.

1

ADJ. TENSION NUT

3

HUB

1

TT25 TT50

TT35 TT70

QTY. REG.*

SPARE PARTS

UNIT TT25

UNIT TT35

UNIT TT50

UNIT TT70

* PER UNIT

B

G E

C

E D

J

L

K

A