2205 p2.pdf – Braeburn 220550 User Manual

Page 2

5

Connect 1/4" water supply tube to brass filter at inlet of solenoid.

DO NOT USE PLASTIC TUBING IN CONTACT WITH ANY

HOT PLENUM SURFACE OR DUCT. IF USING PLASTIC

TUBING, USE INSERT FOR PLASTIC TUBING AND

PLASTIC COMPRESSION SLEEVE (INCLUDED WITH

SADDLE VALVE KIT).

Turn damper knob to winter (open) position.

Turn on water supply and check operation of

humidifier. Set humidistat to a demand setting. With

the furnace off, the solenoid valve should be closed.

Start the furnace. The solenoid valve should open

when the blower or burner circuit is energized.

Check flow of water through distributor trough and

evaporator pad. The standard yellow orifice will

supply approximately 3.5 GPH of water at a line

water pressure of 60 psi. Leave humidistat set at the

recommended setting.

Connect drain hose to

1/2"

spout

on

humidifier

cabinet

using hose clamp.

Run 1/2" hose to

suitable drain such as

floor drain, sewer or

laundry sink. Be sure

hose has continuous

slope and is not kinked

at any point.

8

6

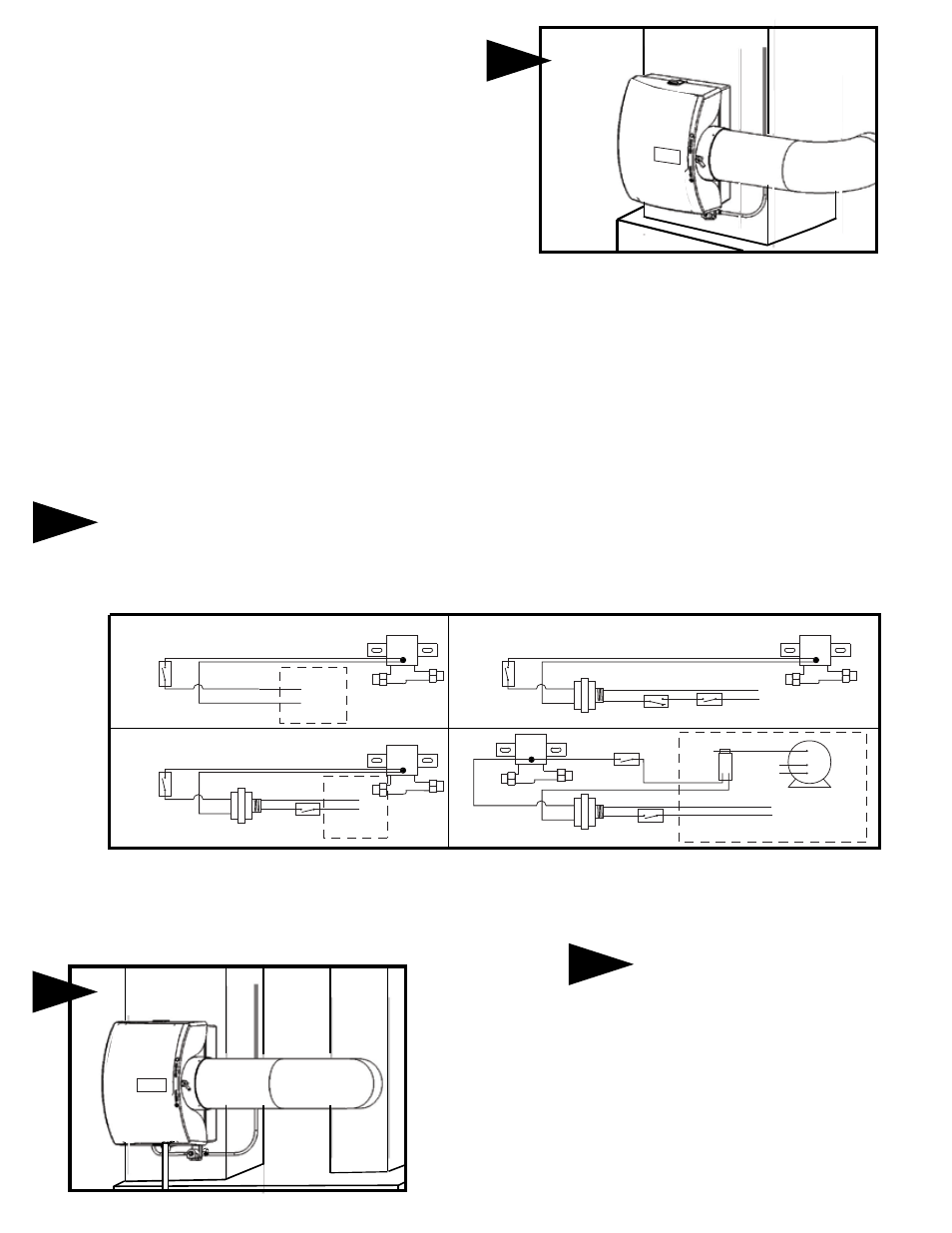

HUMIDISTAT

WIRING

PLEASE SEE COMPLETE SET OF INSTRUCTIONS SUPPLIED WITH HUMIDISTAT

7

ACC

EAC

(HOT)

C

115v.

60CY.

ON-OFF SWITCH

COMMON LEAD

FURNACE

C

HI

LO

229050

CURRENT

SENSING

RELAY

MULTI

SPEED

BLOWER

MOTOR

24V. SOLENOID VALVE

HUMIDISTAT

24 V. TRANSFORMER

ACC

EAC

(HOT)

C

115v.

60CY.

ON-OFF SWITCH

24V. SOLENOID VALVE

24V. SOLENOID VALVE

24 V. TRANSFORMER

L1

C

NO

(HOT)

L2

115v.

60CY.

ON-OFF SWITCH

AIR PRESSURE

SWITCH

24 V. TRANSFORMER

HUM

FURNACE

CONTROL BOARD

C

24v.

60CY.

24V. SOLENOID VALVE

HUMIDISTAT

HUMIDISTAT

HUMIDISTAT

FURNACE

BOARD

PRECAUTIONS

The installer should be a qualified Technician. Disconnect electrical power before beginning installation. Install

the humidistat on the return duct using the foam gasket. Conduct a thorough checkout before leaving the

installation.

THE BRAEBURN

®

220500 INCLUDES MANUAL HUMIDISTAT (MODEL 229100)

THE BRAEBURN

®

220550 INCLUDES DIGITAL HUMIDISTAT (MODEL 229150)

SADDLE VALVE INSTALLATION INSTRUCTIONS

Copper Pipe

1. Retract piercing pin into valve body by turning handle counterclockwise.

2. Screw valve body into upper bracket and tighten.

3. Place rubber gasket over piercing pin.

4. Assemble saddle valve over copper pipe using enclosed screws,

nuts and lower bracket.

5. Tighten screws evenly and firmly. Brackets should be parallel.

6. Complete compression connection to saddle valve outlet.

7. Turn handle clockwise to pierce tubing and close saddle valve.

8. Turn handle counterclockwise to open saddle valve. Leave open for several

seconds to flush dirt from pipe and tubing.

Steel, Brass or Hard Plastic Pipe

1. Shut off water supply and drain the water from the supply pipe.

2. Turn handle clockwise to expose piercing pin and close saddle valve.

3. Place rubber gasket over piercing pin.

4. Drill 1/8" hole in pipe using a hand crank drill to reduce shock hazard.

5. Assemble saddle valve over steel, brass or hard plastic pipe using enclosed

screws, nuts and lower bracket.

6. Tighten screws evenly and firmly. Brackets should be parallel.

7. Complete compression connection to saddle valve outlet.

8. Turn handle counterclockwise to open saddle valve. Leave open for several

seconds to flush dirt from pipe and tubing.

Threaded Pipe Fittings

1. Turn handle clockwise to expose piercing pin and close saddle valve.

2. Seal valve body threads using pipe tape or sealant.

3. Install valve into 1/8" NPT fitting.

4. Complete compression connection to saddle valve outlet.

5. Turn handle counterclockwise to open saddle valve. Leave open for several

seconds to flush dirt from pipe and tubing.