Shr 5500 series, Aisle planning guide, Technical information – Crown Equipment Heavy-Duty Walkie Reach Stacker SHR 5500 Series User Manual

Page 4

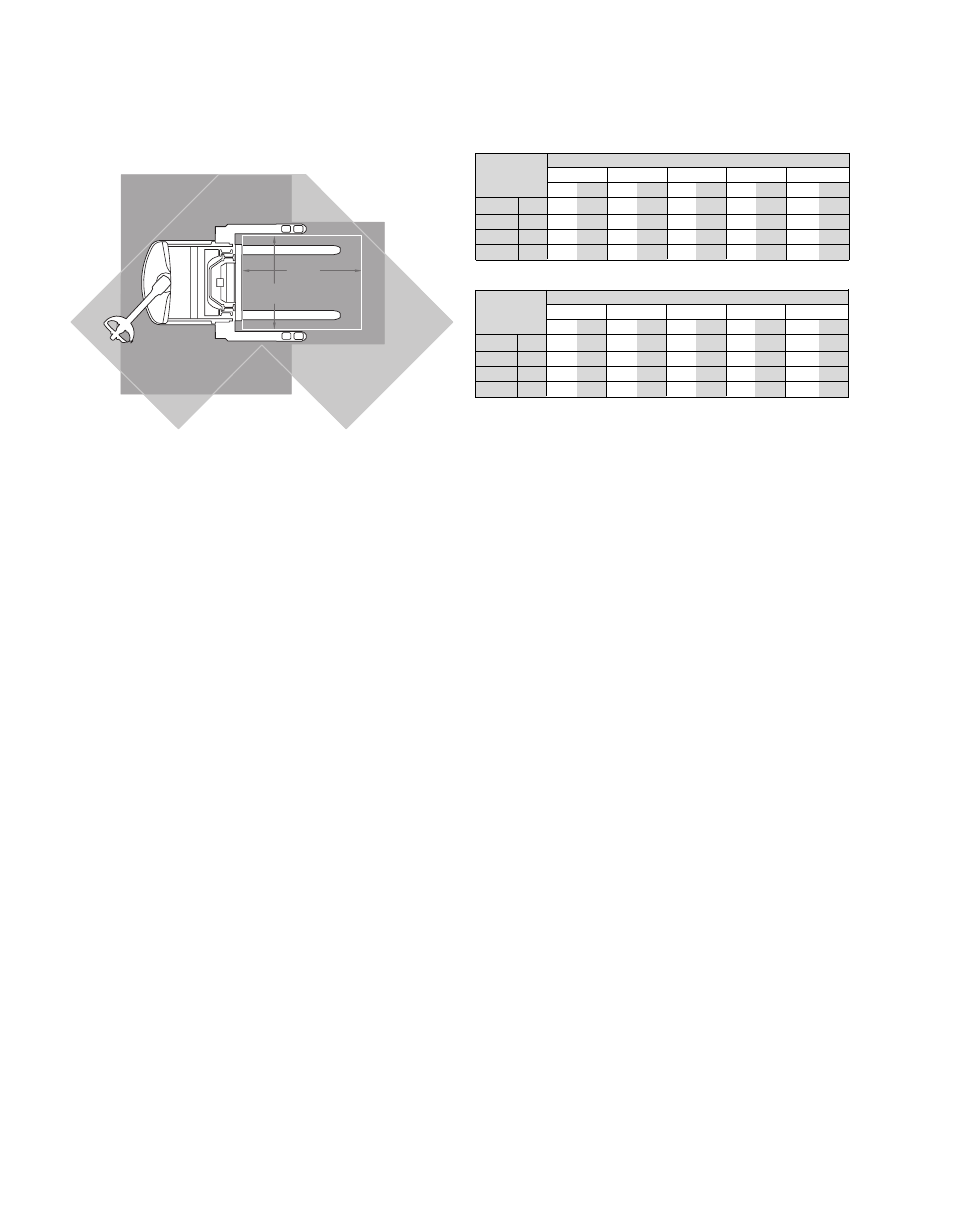

SHR 5500 Series

Aisle Planning Guide

SHR 5520

Pallet Length

Pallet

30

36

40

42

48

Width

A

B

A

B

A

B

A

B

A

B

36

in

62

78

62

81

62

85

62

89

62

97

40

in

64

78

64

82

64

87

64

90

64

97

42

in

65

78

65

81

65

88

65

90

66

97

48

in

68

80

68

83

68

87

68

91

69

99

B

Right Angle Aisles

Pallet

Length

Pallet

Width

A

Equal Intersecting Aisles

A = Equal Intersecting Aisles

B = Right Angle Aisles

Add 2.5" if side shift option is used.

Add 6" to 12" to all aisle dimensions for maximum maneuverability.

SHR 5540

Pallet Length

Pallet

30

36

40

42

48

Width

A

B

A

B

A

B

A

B

A

B

36

in

65

83

65

86

66

92

66

95

66

102

40

in

68

84

68

87

68

92

68

95

68

102

42

in

68

84

68

86

68

93

68

95

69

103

48

in

72

85

72

87

72

93

72

96

72

104

Capacity

Model SHR 5520-25: 2500 lb

at 24" load center

Model SHR 5520-30: 3000 lb

at 24" load center

Model SHR 5540-35: 3500 lb

at 24" load center

Maximum Battery Size

SHR 5520-25: 6.62" wide

x 34.37" long x 24.8" high –

up to 300 amp hours, 24 volts

SHR 5520-30: 6.62" wide

x 34.37" long x 24.8" high –

up to 300 amp hours, 24 volts

SHR 5540-35: 13.12" wide

x 31.10" long x 24.8" high –

up to 660 amp hours, 24 volts

Standard Equipment

1.

24-volt electrical system

2. Crown’s Access 1 2 3

®

Comprehensive

System Control

3. Access 1 2 3 display

• Eight-character scrolling

display, 5 button access

• Three selectable

performance levels

• BDI with lift interrrupt

• Five hour meters

• Event codes

• Access 1 2 3

diagnostics with real

time troubleshooting

• PIN code capability

4.

AC traction and steer motors

Optional Equipment

1.

30 amp on-board charger

(6.62" battery box)

2.

Keyless on-off switch

3.

Work Assist™ Accessories:

• Clip pad

• Hook

• Clip pad and hook

• Pocket

• Fan

4. Sideshift with internal hosing

5. Optional fork lengths (30",

39", 42", 45", 48", 54", 60")

6. Freezer conditioning

(Continuous -30° C / -22° F)

7.

Plexiglass safety shield

8. 10" dia. x 4" wide drive tire

• Soft poly

• Siped soft poly

9. Polyurethane load wheels

• 4" dia. x 2.88" wide

• 10.5" dia. x 4" wide

10. InfoLink

®

ready

11. SBE 160 battery connector

5.

Performance enhancing

features

• X10

®

Handle

• Brake override

• Electronic power steering

• Ramp hold and

speed control

• Power boost

• High-visibility mast

and carriage

• Low profile power unit

• Tool storage tray

6. Wire mesh guard - mast

7.

Volkollan drive tire –

10" dia. x 3" wide

8.

Polyurethane load wheels –

5" dia. x 2.88" wide

9.

InfoPoint

®

System

10. Steel power unit covers

11. 47" tall load backrest

12. Emergency power

disconnect

13. Key switch

14. Horn

15. SB175 gray

battery connector

16. Reversing button

17. Electric park brake

18. Fork tip indicators

19. Battery compartment

rollers

Operator Controls

Crown’s robust X10 handle

places all control buttons in the

optimum position for ease of

operation with either hand and

to minimize hand and wrist

movements. An ergonomic

forward/reverse thumb wheel

allows for precise maneuvering.

The control hand grips are

urethane covered for insulation

from cold and vibration with

integrated horn buttons for easy

activation. The handle contains a

safety button which reverses the

direction of the truck should the

button touch the operator.

The physical efforts to hold the

handle at a comfortable height

was minimized to reduce fatigue.

A rabbit/turtle switch incorpo-

rates two levels of programmable

travel performance so operators

can select the setting that

matches their experience level

or application requirements.

Exclusive brake override feature

allows slow speed travel with

the handle near vertical. This

feature improves maneuverability

in tight areas.

SHR 5500 Series

Technical Information