7 | maintenance – GEA Bock HGX34P 2 pole User Manual

Page 24

24

D

GB

F

E

96116-11.2014-DGbFE

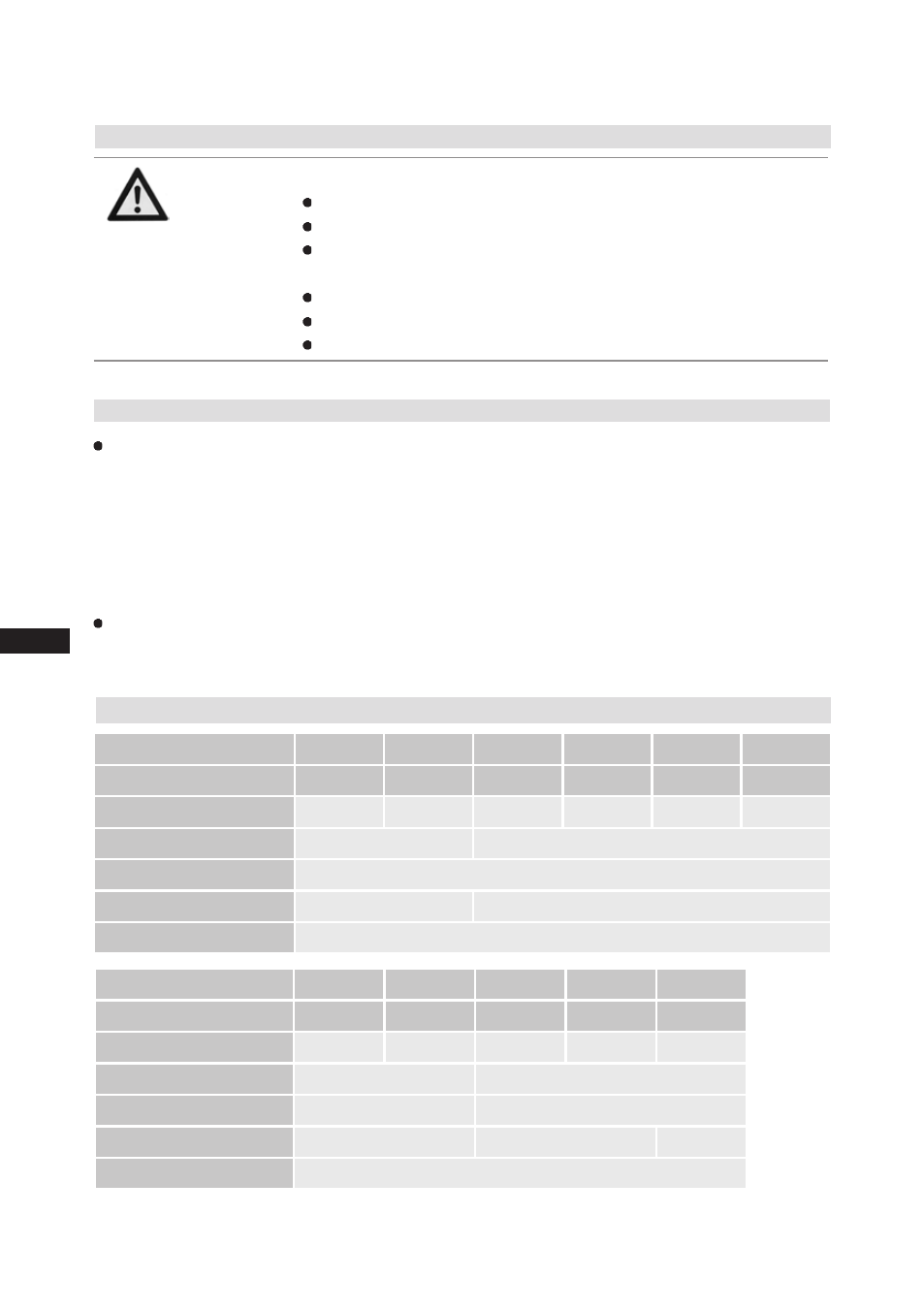

HGX34P / ...

255-2

255-2 A

315-2

315-2 S

315-2 A

315-2 SA

Designation

Item No.

Item No.

Item No.

Item No.

Item No.

Item No.

Set of gaskets

80612

80642

80612

80613

80642

80643

Set valve plate (50 Hz)

80605

80606

Set K valve plate (60 Hz)

- -

Set piston/connecting rod

80608

80609

Set connecting rod

80368

HGX34P / ...

380-2

380-2 A

315-2 AK 315-2 SAK 380-2 AK

Designation

Item No.

Item No.

Item No.

Item No.

Item No.

Set of gaskets

80613

80643

80753

80754

80754

Set valve plate (50 Hz)

80606

- -

Set K valve plate (60 Hz)

- -

80757

Set piston/connecting rod

80610

80609

80610

Set connecting rod

80368

Only use genuine GEA Bock spare parts!

7.3 Spare parts recommendation

7.2 Work to be carried out

Oil change: In principle, an oil change is not mandatory if the system is correctly manufactured

and operated. However, based on decades of experience we recommend that the following oil

change/service work is carried out:

- First oil change during the first maintenance of the system.

- Then after every 10,000 - 12,000 operating hours, though no more than 3 years, clean the

oil strainer at the same time. Dispose of the oil inside in accordance with the applicable

national regulations.

Annual checks: Oil level, leak tightness, running noises, pressures, temperatures, function of

auxiliary devices such as oil sump heater, pressure switch.

7.1 Preparation

7| Maintenance

WARNING

Before starting any work on the compressor:

Switch off the compressor and secure it to prevent a restart.

Relieve compressor of system pressure.

Prevent air from infiltrating the system!

After maintenance has been performed:

Connect safety switch.

Evacuate compressor.

Release switch lock.