Spark plug – Cub Cadet 1527 User Manual

Page 22

22

Service the Foam Precleaner

•

Clean the precleaner after every 25 hours of

operation. More often if operating under extremely

dusty or dirty conditions.

•

Wash the precleaner in detergent and water.

•

Rinse the precleaner thoroughly until all traces of

detergent are eliminated. Squeeze out excess

water — DO NOT WRING. Allow the foam element

to air dry.

Service Paper Element

NOTE:

Refer to the

Attachments & Accessories

table

found on page 32 of this manual for the proper air filter.

The paper element should be replaced at least every

100 hours of operation. Replace more frequently if the

tractor is operated under extremely dusty conditions.

IMPORTANT:

Do not wash the paper element or use

pressurized air, as this will damage the element.

Examine the element and discard if dirt and/or damage

is present.

NOTE:

Handle new elements carefully; do not use if

the sealing surfaces are damaged.

•

Clean any dirt or debris from the air cleaner base

and cover.

•

Check the air cleaner base. Make sure it is secured

and not damaged. Also check the air cleaner cover

for damage or improper fit. Replace all damaged air

cleaner components.

Air Filter Installation

Model 1525 ONLY

•

Carefully install the paper element and foam

precleaner in the air cleaner cover.

•

Insert the two hooks on the bottom of the cover into

the two channels of the air cleaner base. Refer to

Figure 19.

•

Rotate the top of the cover upward and guide the

cover latches through the top slots in the base.

Push the top of the cover rearward until the latches

snap upward and lock the cover in place.

IMPORTANT:

Make certain the cover latches are

captured in the base slots. Failure to do so may allow

the cover to loosen and allow unfiltered air to be

ingested by the engine, resulting in premature wear and

failure of the engine.

Model 1527 ONLY

•

Carefully Install the element (with precleaner) on

the base and secure it with the wing nut.

•

Position the air cleaner cover over the base and

hook the clasps behind the tabs on the base. Refer

to Figure 19.

•

Push the clasps inward toward the cover to lock

them in the closed position.

Spark Plug

Every 100 hours of operation, remove each spark

plug, check its condition, and reset the gap or replace

with a new plug as necessary.

NOTE:

Refer to the

Attachments & Accessories

table

found on page 32 of this manual for the proper spark

plug type.

•

Lift the tractor’s hood and locate the spark plug

wires on each side of the engine.

•

Carefully pull the spark plug wire boots off of the

spark plugs.

•

Before removing the spark plug, clean the area

around the base of the plug to keep dirt and debris

out of the engine.

•

Using a spark plug socket, remove the spark plugs

and check their condition.

•

Replace a plug if worn or damaged. Clean minor

carbon deposits from the electrode using a soft wire

brush. Check and re-set the gap as instructed in the

following steps.

NOTE:

Do not clean the spark plug in a machine

using abrasive grit. Some grit could remain in the spark

plug and enter the engine causing extensive wear and

damage.

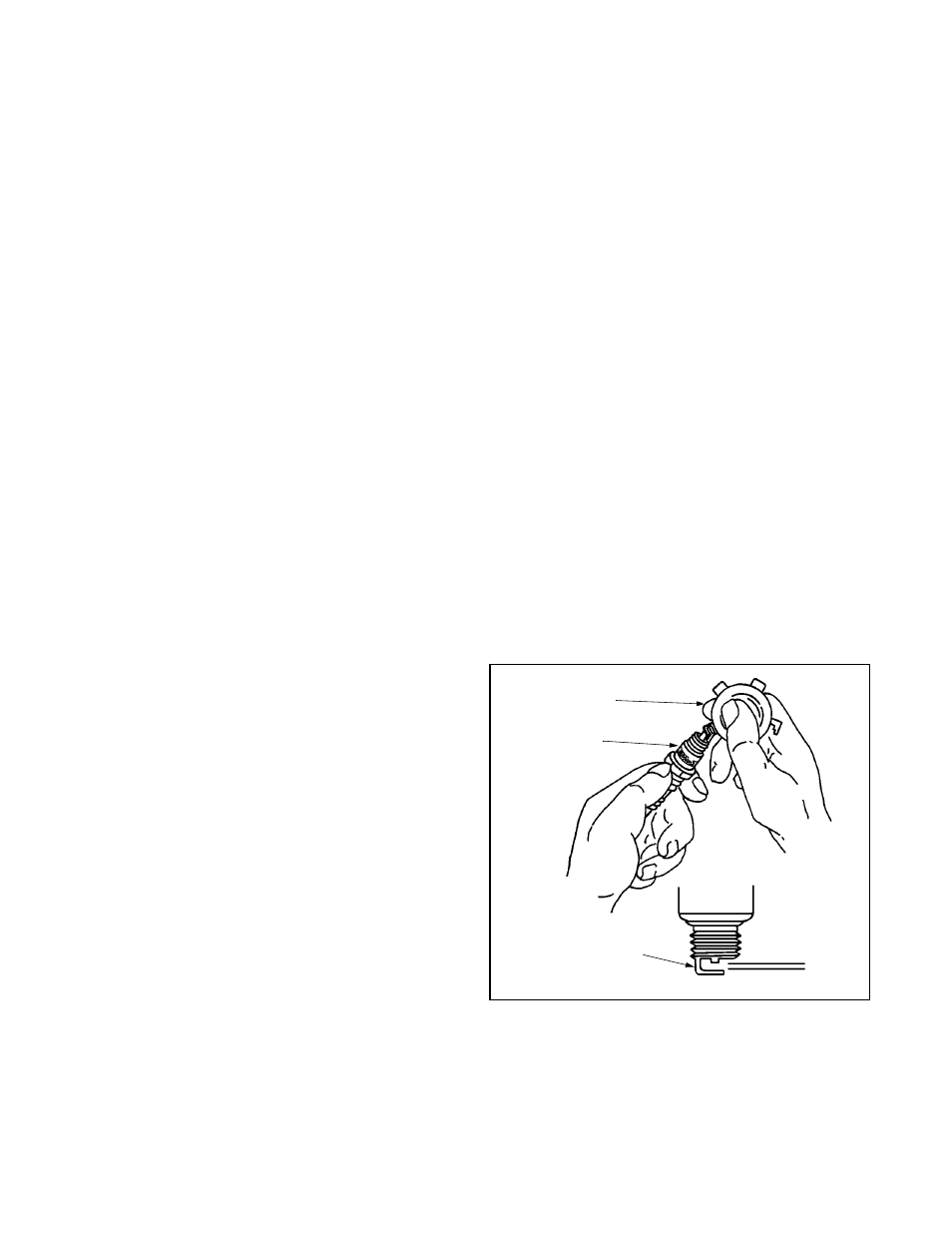

•

Check the gap using a feeler gauge and adjust, if

necessary, by carefully bending the ground

electrode. See Figure 20. Set the spark plug gap to

0.75 mm (0.030 in.).

Figure 20

•

Reinstall the spark plugs into the cylinder heads.

Torque the spark plug to 22 N·m (16 ft. lb.).

•

Place the spark plug wire boots over the spark

plugs and press until you feel the plug wire

connectors snap over the terminal of the spark

plugs.

Feeler Gauge

Ground Electrode

Spark Plug

Gap