Cub Cadet 6 Fabricated Deck User Manual

Page 22

22

Note:

W

hen adding hydraulic oil, do so in

small quantities and recheck the oil level before

adding more. It is important that you do not over-

fill the reservoir to allow for fluid expansion.

1.

Hoses: Check the hoses from the hydraulic oil

tank to the oil filter to the hydraulic lines daily for

leaks or abrasion and replace any damaged

hoses. Make certain there are no kinks or twists

in any hose.

2.

Hydraulic Oil Tank and Filter:

Note:

Change the hydraulic oil and the oil fil-

ter element after the first 50 hours of operation

and every 500 hours thereafter.

To drain the hydraulic oil tank, place a 1 gallon drain pan

under the drain plug on the bottom of the hydraulic oil

tank. Remove the drain plug, drain the tank, then

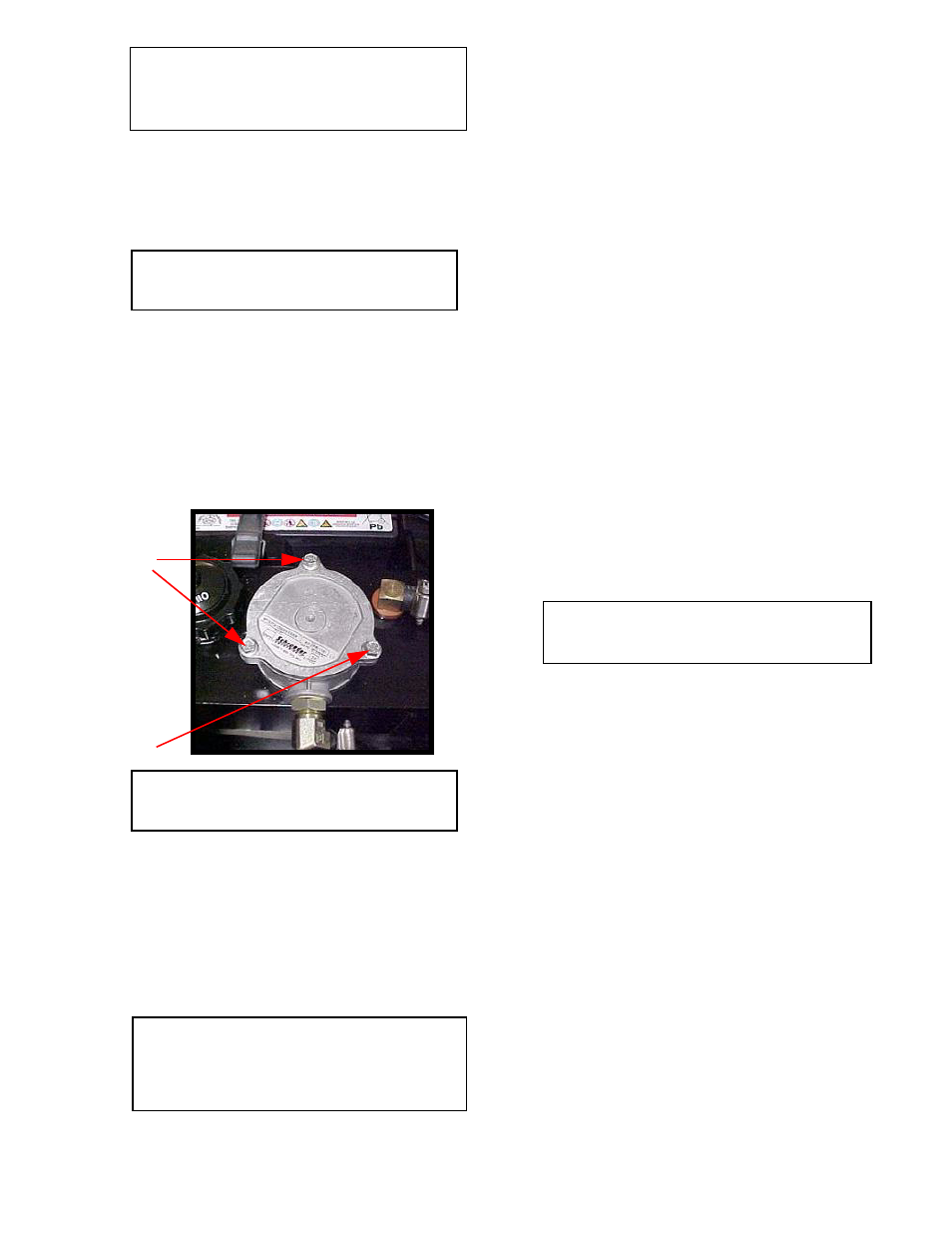

replace the plug. Remove the three screws from the top

of the oil filter and take out the oil filter element You don’t

have to drain the rest of the hydraulic system. Put the

replacement filter element in the oil filter and lubricate

the sealing surface. Install the three screws in the top of

the oil filter to secure the oil filter element. (See photo

below)

Note:

Always wipe off the hydraulic tank fill

cap and the area around it before removing the

cap to prevent dirt from contaminating the oil.

Remove the fill cap and fill the tank with the same 15W-

40 oil selected for the filter until the oil level is a 1/4”

below the oil tank fill neck. Leave this air space for

expansion. Start the engine and let it run at idle for

about five minutes. Check the filter for leaks. Idling the

engine and the pumps in this way will purge any air from

the system. Shut off the engine and recheck the oil level

in the tank. Top-off if necessary until the oil level is a 1/4”

below the oil tank fill neck.

Note:

After unit is up to operating tempera-

ture, turn off engine and re-check hydraulic oil. If

oil appears foamy or contains excessive air bub-

bles, DO NOT OPERATE UNIT. Contact service

technician.

3.

Hydrostatic Pumps and Motors: The pumps

are the hardest-working components in the

hydraulic system. They are in operation all the

time the engine is running. Because of

extremely close tolerances, wear is an important

factor in their life. Contaminants in the hydraulic

oil and cavitation does the greatest harm to the

pumps. Cavitation is a blockage in the supply

lines that produces a partial vacuum causing

violent bubbling in the hydraulic oil in the pump.

Check the two suction hoses (the hoses con-

nected to the filter) daily before starting the

engine. Look for a flattened condition or any

leaks and repair or replace as necessary. A flat-

tened or leakng suction hose will permit cavita-

tion to develop which can destroy the pumps in a

short time.

Contaminants or foreign matter in the oil will also

damage the pumps . To prevent this, use a filter

that captures particles as small as 25 microns or

25 millionths of a meter in diameter. You can

help in the battle against dirt by being very care-

ful when you remove or repair a component in

the hydraulic system. Thoroughly clean off any

component before you work on it. Plug the ends

of any hose or line you remove with a rubber or

plastic plug. Use plastic caps to seal off the ends

of hydraulic fittings. Place any component you

remove in a clean plastic bag so it can’t pick up

dust or dirt. Clean your hands frequently when

working on the hydraulic components.

Note:

The pumps are not owner-repairable. If

a pump fails, contact your Cub Cadet Commer-

cial dealer. Do not disassemble the pump.

4.

Steering Lever Adjustments: The steering

lever controls on this Zero Turn Mower (ZTM)

incorporate a patented interlock mechanism that

secures them in their Neutral position whenever

the Park Brake lever is applied. Additionally, the

lap bars can be opened in any position - Neutral,

when traveling Forward, when traveling in

Reverse, or when executing a zero-turn maneu-

var. The lap bars also incorporate a Return-To-

Neutral (RTN) feature with hydraulic dampers to

provide smooth, non-jerkey, control motion while

affording an automatic hydrostatic braking

means.

Whenever the Park Brake lever is moved rear-

ward to the Park Brake engaged position, a

cable mechanism, connected to each drum

brake on the hydrostatic wheel motors, applies

force to each brake lever so that each wheel

brake mechanism can prevent brake drum and

wheel rotation. At the same time, a second cable

and linkage mechanism is activated to secure

both lap bars in their Neutral positions and to

activate the Park Brake switch. Both lap bars

must be in their Neutral positions for the neutral

lock linkage to function - the spring-loaded link-

age will force rods in through aligning holes in

Screw

Screw