Cub Cadet 997 User Manual

Page 32

32

A. Fasteners

B. Recoil Starter

C. Air Cleaner Case

D. Air Cleaner body

E. Latches

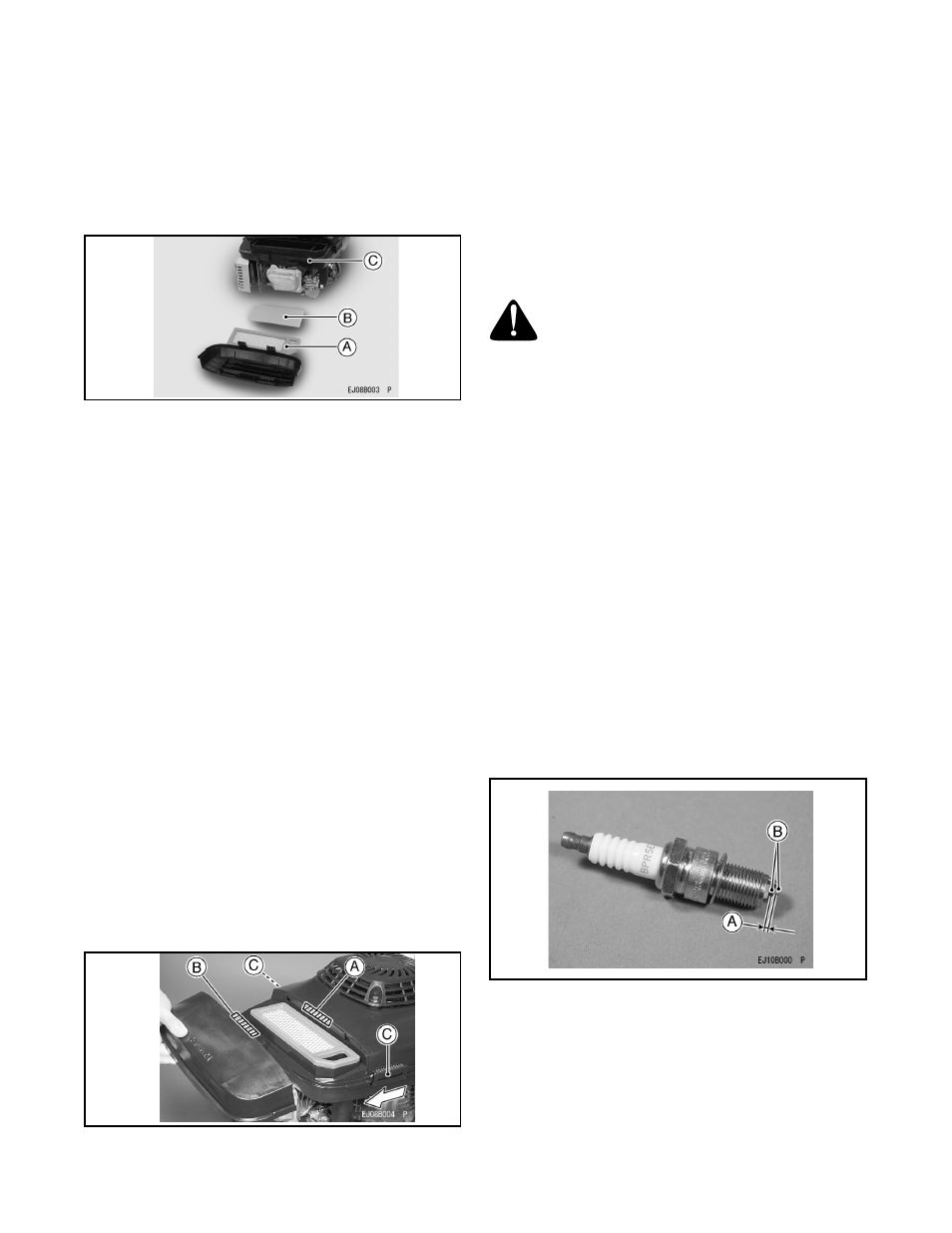

Remove the paper element (A) and the foam element

(B) from the air cleaner body (C).

Figure 15

A. Paper Element

B. Foam Element

C. Air Cleaner body

Foam Element

Clean the foam element every 25 hours.

Wash the element in detergent and water, and dry it

thoroughly.

CAUTION: Do not oil foam element.

Paper Element

•

Clean the paper element every 100 hours.

•

Clean the element by tapping gently to remove

dust. If very dirty, replace the element.

•

Replace paper-element yearly or every 300 hours.

CAUTION: Do not wash paper-element. Do not use

pressurized air to clean or dry paper element.

NOTE: Operating in a dusty condition may require

more frequent maintenance than above.

•

Reinstall the foam element and then the paper

element on the air cleaner body.

•

Reinstall the air cleaner case on the air cleaner

body by first fitting the projection (B) on the edge of

the air cleaner case into the slit (A) in the air cleaner

body. Then, sliding the fasteners (C) toward the air

cleaner case, securely fasten the air cleaner case

with the air cleaner body.

Figure 16

A. Slit in the air cleaner body

B. Projection on the air cleaner case

C. Fasteners

CAUTION: After servicing the air cleaner, be sure

all the removed parts are reinstalled properly in

place. Failure to secure fastening of the air cleaner

case with the air cleaner body may cause dirt or

other foreign materials to enter the engine, while it

is running, through the air cleaner, resulting in

engine troubles or failures.

•

Clean or replace the spark plug and reset gap (A)

every 100 hours of operation.

•

Disconnect the spark plug cap from spark plug and

remove the spark plug.

•

Clean the electrodes (B) by scraping or with a wire

brush to remove carbon deposits.

•

Inspect for cracked porcelain or other wear and

damage. Replace the spark plug with a new one if

necessary.

•

Check the spark plug gap and reset it if necessary.

The gap must be between 0.7 and 0.8 mm (0.028

and 0.032").

To change the gap, bend only the side-electrode, using

a spark plug tool.

-Install and tighten the spark plug to 23 N-m (2.3kgf-m,

17fMb).

-Fit the spark plug cap on the spark plug securely.

-Pull up the spark plug cap lightly to make sure of the

installation of the spark plug cap.

Recommended Spark Plug

NGK... BPR5ES

Figure 17

A.

Spark Plug Gap

B.

Electrodes

CAUTION: Be sure to use the same type of spark

plug for change. Resistor spark plug is required in

some areas by local law.

WARNING:

Hot engine components can

cause severe burns. Stop engine and allow it to

cool before checking spark plug.