Blue Sky Solar Boost 2000E User Manual

Page 7

Installation and Operation Manual

6

SELECTING PV MODULES

Voltage, current and power produced by Photovoltaic (PV) modules fluctuate widely with operating conditions. As a result a set of test conditions

referred to as Standard Test Conditions (STC) are used to rate modules in a meaningful manner and accurately predict real world performance. STC

ratings are not maximum or optimal ratings. Conditions can be present where V

OC

and I

SC

approach 1.25 times STC ratings which is why National Electrical

Code and our recommendations call for 1.25 derating of both V

OC

and I

SC

. Yet in real world conditions I

MP

is commonly only about 75 – 80% of I

MP

at STC.

Key PV module specifications;

P

MAX

Maximum power in watts (P

MAX

= V

MP

x I

MP

)

V

OC

Voltage with module open circuit (typically

≈20 – 22V for 12V nominal modules)

V

MP

Voltage where module produces Maximum Power (typically

≈17 – 18V for 12V nominal modules)

I

MP

Current where module produces Maximum Power

I

SC

Current with module Short Circuit

The 2000E will provide the best MPPT current boost performance if all PV modules are identical. Dissimilar modules should have V

MP

values within

≈0.5V or better and be of the same basic cell technology so their V

MP

will tend to track as operating conditions change. If module types are very different

consider using a separate charge controller for each module type to obtain the best MPPT current boost performance. Select PV modules that do not exceed

the maximum ratings shown below, and preferably produce at least 3.5 amps of I

MP

per 100 amp-hours of battery capacity. For more detail on PV module

sizing see technical bulletin #100214 at

www.blueskyenergyinc.com

.

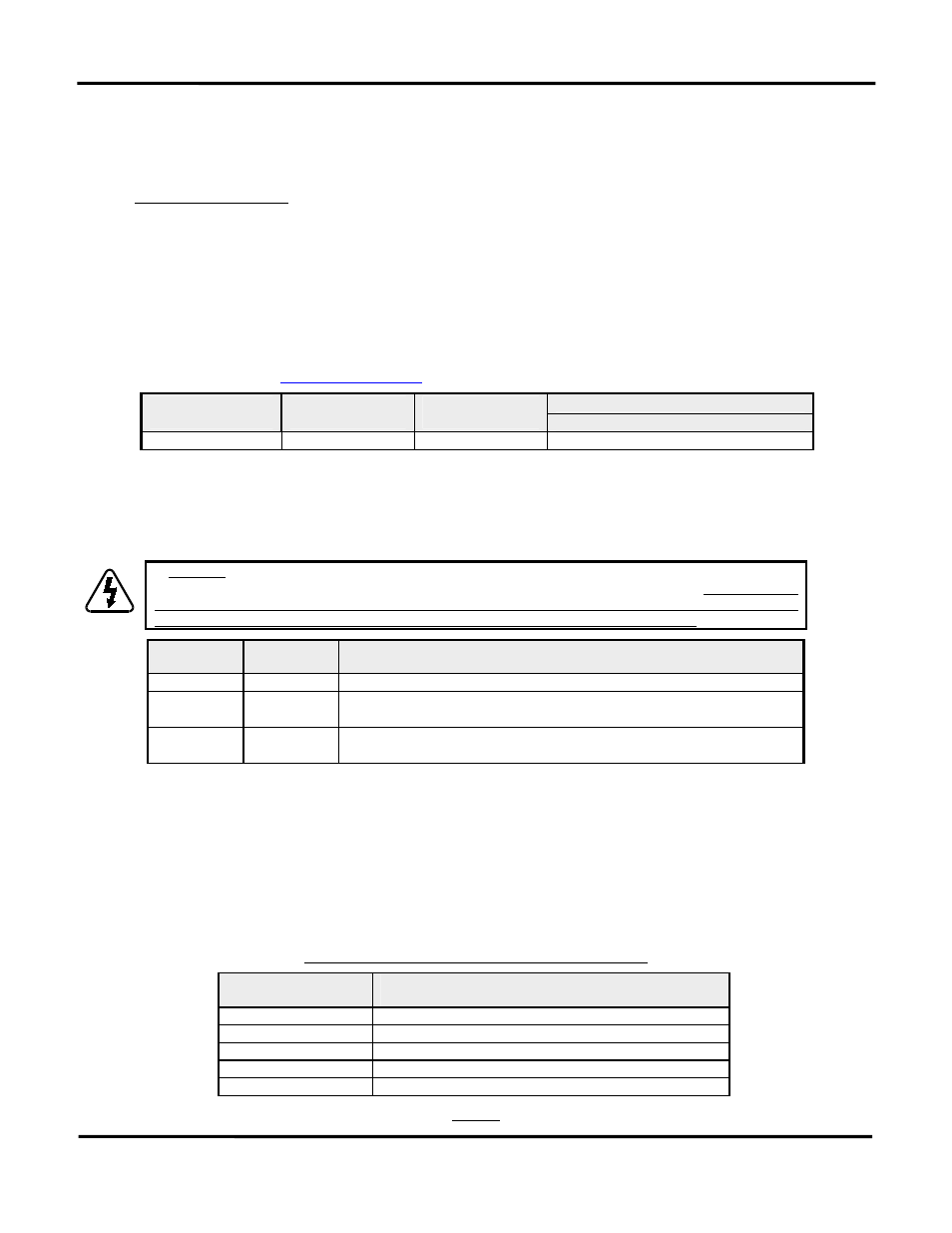

Maximum PV Power @

STC

Maximum PV

Isc @ STC

Maximum PV

V

OC

@ STC

Recommended range of V

MP

at STC

Nominal 12V PV

340W

20A

24.0V

16.5 – 18.5V

TEMPERATURE COMPENSATION

For temperature compensation to operate, battery temperature sensor p/n 930-0022-20 must be installed and temperature compensation enabled via dip

switches 3 & 4. The sensor is electrically isolated and may mount to any battery terminal, but battery negative is preferred. Select a temperature compensation

characteristic that most closely matches the battery manufacturers recommendation. Most 12 volt flooded or GEL lead-acid chemistry batteries require the –

30.0 millivolts/

°C (–5.00mV/°C/cell) setting. NiCd and many lead-acid chemistry AGM type batteries require the –20.0 millivolts/°C (–3.33mV/°C/cell) setting.

¾

WARNING: Do not attach a sensor or any connections other than Blue Sky Energy battery temperature sensor p/n 930-0022-20

to the temperature sensor terminals. Be certain to observe proper RED/BLK polarity as shown in Figure 3. The 2000E cannot

properly limit and control battery voltage if temperature compensation is enabled with the sensor installed reverse polarity.

Additionally, output current will be disabled if temperature compensation is enabled without the sensor installed.

SWITCH

3

SWITCH

4

TEMPERATURE COMPENSATION

OFF OFF

DISABLED

ON ON

–30.0 millivolts/

°C

Flooded Lead-Acid (–5.00mV/

°C/cell • 6 cells)

ON

OFF

–20.0 millivolts/

°C

NiCd (–2.00mV/

°C/cell • 10 cells) ♦ AGM Lead-Acid (–3.33mV/°C/cell • 6 cells)

BATTERY AND PV WIRING

The 2000E panel should be mounted in a dry location that provides easy routing of large size wires to the PV array and battery, and keeps PV/battery wire

length as short as practical. The location should also provide free air circulation around the front of the panel, and if possible, around the rear. Take great care not

to touch or damage circuit board components as this damage is not covered under the limited warranty. Figure 4 provides a 1:1 template for the panel cut-out.

Wiring and connections used with the 2000E can have a significant effect on current boost performance. The 2000E increases charge current by

transforming previously wasted or unharvested power into useable charge current. The effect wiring has on current boost performance is that power wasted

heating wires or connections is power that becomes unavailable to charge the battery. A desirable installation will produce a total system wiring voltage drop of 3%

or less. The lengths shown in Table 2 are one way from the PV modules to the battery with the 2000E located along the path. Wire length can be increased

inversely proportional to actual current. If current was reduced by ½ (to 10 amps), wire lengths could be doubled and still provide the same 3% voltage drop.

MAXIMUM CONDUCTOR PAIR LENGTH – 3% VOLTAGE DROP

WIRE GAUGE

AWG

12 VOLT SYSTEM @20AMPS

FEET / METERS

12 AWG

6.4 / 1.9

10 AWG

10.2 / 3.1

8 AWG

16.2 / 4.9

6 AWG

25.7 / 7.8

4 AWG

40.8 / 12.5

TABLE 2