Trouble shooting guide – AquaFX The AquaFX Stingray User Manual

Page 8

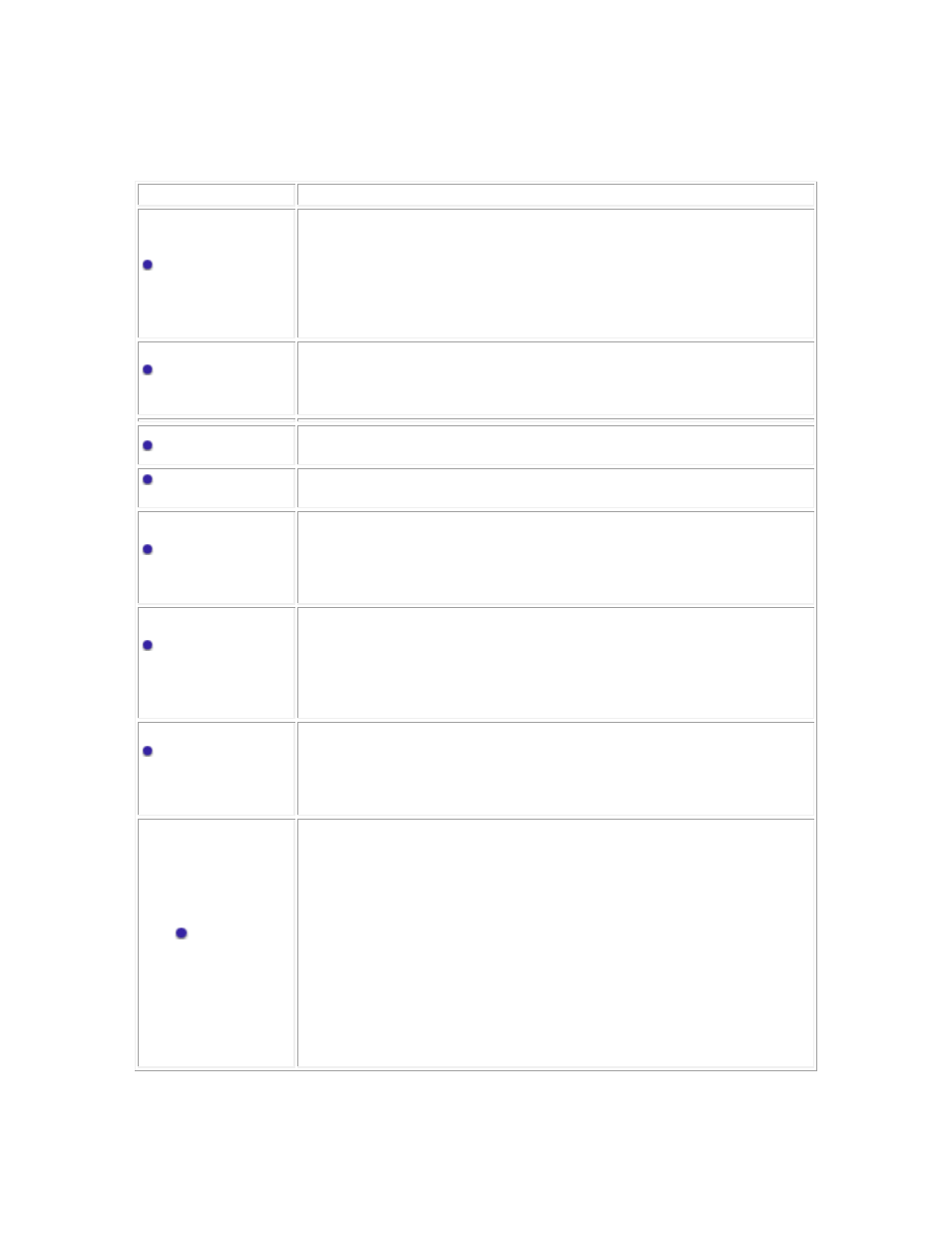

Trouble shooting guide

Problem

Solution

High TDS after

membrane

Clogged Pre-filters. Causing Pressure Drop. Insufficient pressure will yield

poor TDS rejection from RO membranes. Change Pre-Filters.

Average Membrane life is 2 to 3 years. Most common cause for

membrane failure is insufficient pre-filter maintenance. AquaFX Carbons

are rated for 3,750 gal @ 1.0 GPM of 2ppm Chlorine. Do not exclude

drain water from this capacity, as it is treated water. Very high TDS

(>550ppm) may also yield premature failure.

Low incoming water

pressure.

Incoming water pressure must be above 40 PSI, Add a booster pump if

below 40psig. Make sure Pre-Filters are not clogged causing low

pressure.

No water to drain.

Flow Restrictor is clogged, Replace Drain Flow Restrictor. (rare)

Check to see if water is turned on.

All water is going

out of the drain

With no back pressure, most of the water will exit out of the drain. Make

sure a Flow restrictor is present.

Very little/slow

water production

Reference units flow rate vs. actual production. Slow flow from RO is

normal. Cold water, low pressure and high contaminant levels will

contribute to decreasing the rate of water production. Heating water (NO

WARMER THEN 80 Degrees F), increasing pressure or additional pre-

filtration will help to counteract these adverse affects.

Drain Water

Continues After

Product line is full

The most common cause of a ‘continuing drain’ is a pressure leak on the

product side of the RO. If the pressure cannot build, the automatic shut-off

(ASO) will not close. Check ASO with a ball valve right after RO. Close

Ball valve then wait 1-3 minutes. If drain continues, replace ASO Valve. If

it stops, have the customer, find then stop pressure leak. If a float valve is

being used, it is more than likely the culprit.

The incoming feed

water TDS has

increased.

An increase in feed water TDS will also give an increase in Product Water

TDS. R.O. (Dolphin) Users will see this rise in TDS, due to the membrane

removes a percentage of TDS.

RO/DI (Barracuda, Mako, Great White) Users will not see this rise, but the

DI will exhaust faster than normal.

DI is

exhausting

very fast

R.O. Membranes are manufactured with a preservative on them, if your initial

startup allows the membrane to ‘rinse’ into the DI; there will be some immediate

exhaustion, followed by normal exhaustion.

Chloramines Vs Chlorine

– If the customer’s water is disinfected with

Chloramines (NH

2

CL) the ammonia portion will still be present post RO.

For R.O. (Dolphin) users, they may wish to purchase DI to remove the

ammonia..

RO/DI (Barracuda, Mako, and Great White) users will have the ammonia

removed by the DI. This will tax the DI, Chloramines appears in several

forms, so the decreased life would depend on the state of Chloramines.

(mono, di or tri)